Yb-containing deformation magnesium alloy and dynamic precipitation strengthening-toughening preparation thereof

A deformed magnesium alloy, strengthening and toughening technology, applied in the field of metal material strengthening and processing, can solve the problems of insignificant strengthening effect, difficulty in obtaining precipitation strengthening effect, single strengthening and toughening effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

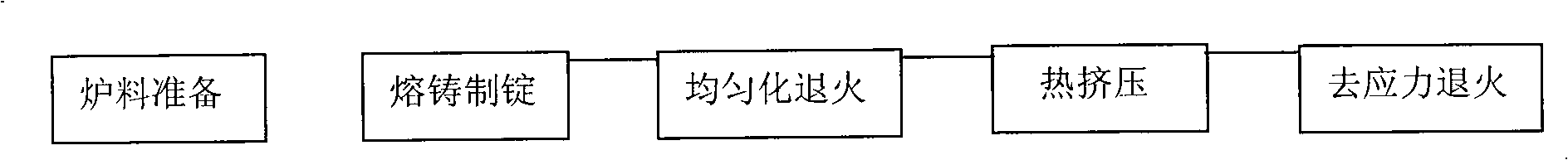

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Melt the magnesium ingot with a resistance heating furnace, then add a Mg-Zr alloy containing 1.5% of the total mass of the material added in this step at 770 ° C, and stir for 6 minutes under solvent protection conditions, and then in Add the Mg-Yb alloy containing 2.0% of the total mass of materials added in this step at 750° C., stir for 4 minutes to help melting, and finally add zinc ingots with 6.0% of the total mass of materials added in this step at 730° C., stir for 1 minute to help melt, After standing at 730°C for 15 minutes, remove the slag and pour the ingot. Place the ingot in a heat treatment furnace with resistance heating and temperature control, and pass through SO 2 After the gas is kept at 380°C for 20 hours, the temperature is then raised to 420°C, held for 6 hours, and then it is taken out of the furnace and cooled naturally outside the furnace; the homogenized ingot is removed by a machine tool to remove 2mm of the skin, and then put ...

Embodiment 2

[0033] Embodiment 2: Melt the magnesium ingot with a resistance heating furnace, then add a Mg-Zr alloy containing 2.0% of the total mass of the material added in this step at 780 ° C, and stir for 5 min under solvent protection conditions, and then in Add the Mg-Yb alloy containing 0.5% of the total mass of materials added in this step at 740° C., stir for 3 minutes to flux, and finally add zinc ingots with 5% of the total mass of materials added in this step at 740° C., stir for 2 minutes to flux, After standing at 740°C for 20 minutes, remove the slag and pour the ingot. Place the ingot in a resistance heating temperature-controlled heat treatment furnace, heat it at 340°C for 16 hours, then raise the temperature to 405°C, hold it for 10 hours, and then put it out of the furnace and put it into a water tank to cool; The outer skin is then placed in an extrusion mold with a temperature control of 320°C to keep warm and preheat for 30 minutes. At this temperature, a hydraulic...

Embodiment 3

[0034]Embodiment 3: the magnesium ingot is melted with a resistance heating furnace, then add a Mg-Zr alloy containing 1.8% of the total mass of the material added in this step at 750 ° C, and stir for 10 min under gas protection conditions, and then in the Add the Mg-Yb alloy containing 0.2% of the total mass of materials added in this step at 760° C., stir for 5 minutes to flux, and finally add zinc ingots with 7% of the total mass of materials added in this step at 750° C., stir for 3 minutes to flux, After standing at 750°C for 10 minutes, remove the slag and pour the ingot. Place the ingot in a resistance heating temperature-controlled heat treatment furnace, heat it at 330°C for 24 hours, then raise the temperature to 400°C, hold it for 4 hours, and then put it out of the furnace and put it into a water tank to cool; The outer skin is then placed in an extrusion die with temperature control at 380°C for heat preservation and preheating for 15 minutes. At this temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com