Water-soluble pore-foaming agent, porous scaffold and preparation method of porous scaffold

A technology of porous scaffolds and porogens, applied in the field of polymer materials and biomaterials, can solve the problems of difficult separation of particles, unsatisfactory scaffold pore structure and connectivity performance, and unobtainable, etc., and achieve the effect of simple and feasible preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

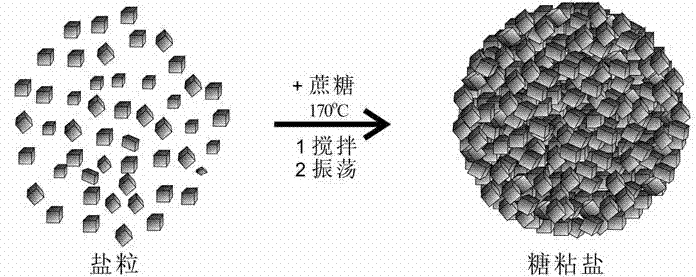

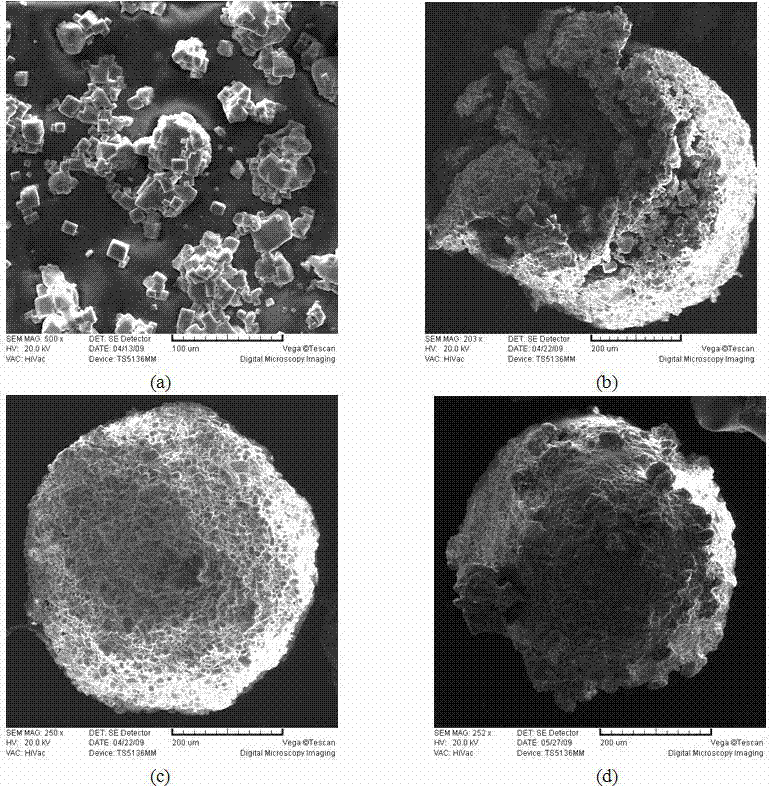

[0043] Add sodium chloride salt grains into a pulverizer, pulverize for 60 seconds to obtain small salt grains, weigh 50 g of small salt grains and 10 g of sucrose into a round bottom flask, place the beaker in an oil bath, and install a mechanical stirring device. The mechanical stirring speed is 300 rpm / min, under the state of stirring, slowly heat the methyl silicone oil to 170 o C, to dissolve the sucrose and bond the small salt particles together. Due to the continuous mechanical stirring, the small salt particles will not be agglomerated as a whole. After 0.5 h, stop stirring and quickly pour the mixture in the flask into the vibrating screen. In the sieve, use the shaking action of the vibrating sieve machine to further form the small particles of sodium chloride bonded into balls while sieving, and after shaking for 0.5 h, a porogen with a diameter of 50-1000 μm in pore size distribution is obtained.

Embodiment 2

[0045] Add sodium chloride salt grains into a pulverizer, pulverize for 60 seconds to obtain small salt grains, weigh 50 g of small salt grains and 10 g of sucrose into a round bottom flask, place the beaker in an oil bath, and install a mechanical stirring device. The mechanical stirring speed is 100 rpm / min, under the state of stirring, slowly heat the methyl silicone oil to 170 o C, to dissolve the sucrose and bond the small salt particles together. Due to the continuous mechanical stirring, the small salt particles will not be agglomerated as a whole. After 0.5 h, stop stirring and quickly pour the mixture in the flask into the vibrating screen. In the sieve, use the shaking action of the vibrating sieve machine to further form the small particles of sodium chloride bonded into balls while sieving, and after shaking for 0.5 h, a porogen with a diameter of 50-1000 μm in pore size distribution is obtained.

Embodiment 3

[0047] Add sodium chloride salt grains into a pulverizer, pulverize for 60 seconds to obtain small salt grains, weigh 50 g of small salt grains and 10 g of sucrose into a round bottom flask, place the beaker in an oil bath, and install a mechanical stirring device. The mechanical stirring speed is 200 rpm / min, under the state of stirring, slowly heat the methyl silicone oil to 170 o C, to dissolve the sucrose and bond the small salt particles together. Due to the continuous mechanical stirring, the small salt particles will not be agglomerated as a whole. After 0.5 h, stop stirring and quickly pour the mixture in the flask into the vibrating screen. In the sieve, use the shaking action of the vibrating sieve machine to further form the small particles of sodium chloride bonded into balls while sieving, and after shaking for 0.5 h, a porogen with a diameter of 50-1000 μm in pore size distribution is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com