Large scale stalk anaerobic fermentation technique and apparatus

An anaerobic fermentation, large-scale technology, applied in the direction of fermentation, fertilization equipment, biochemical cleaning equipment, etc., can solve the problems of non-continuous gas production, no fluidity, low straw density, etc., achieve low cost and reduce waste gas emissions , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

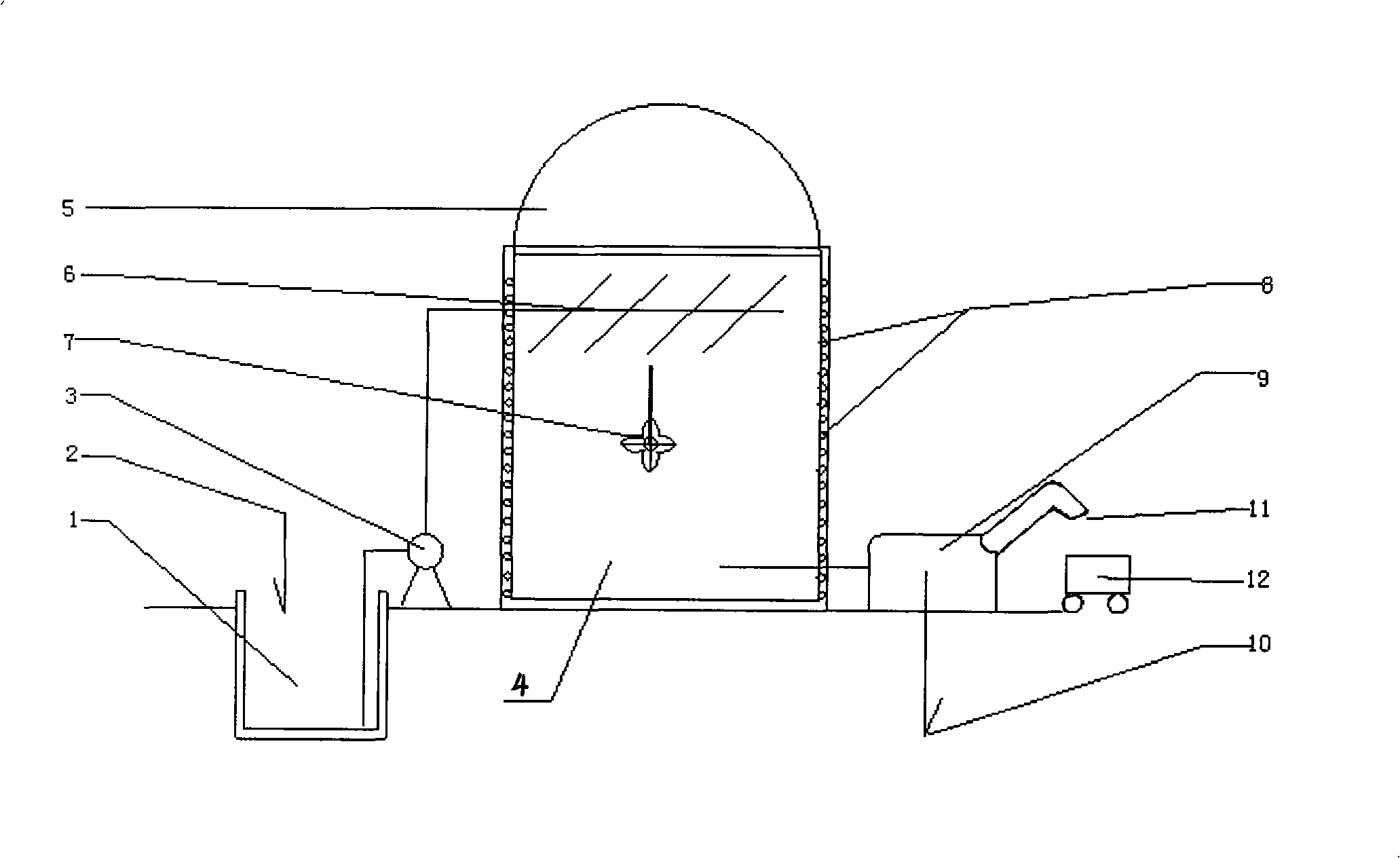

[0039] Anaerobic fermentation device, structure such as figure 1 As shown, the anaerobic bacteria liquid return port 2 is provided on the material tank 1, the raw materials in the material tank enter the anaerobic generator 4 through the pump 3, the top of the anaerobic generator 4 has a rubber storage air bag 5, and the anaerobic generator 4 There is a distributing device 6 on the upper part, the stirring device 7 is located in the middle of the anaerobic generator 4, the steam heating tube coil 8 is coiled on the wall of the anaerobic generator 4, and the outer part is an insulation layer. The lower part of the anaerobic generator 4 is connected to the anaerobic bacteria separation device 9, the bottom of the anaerobic bacteria separation device 9 has an anaerobic bacteria liquid outlet 10, and the upper part of the anaerobic bacteria separation device 9 has a straw organic fertilizer output nozzle 11, which outputs straw organic fertilizer. Below the nozzle 11 is a receiving ca...

Embodiment 2

[0040] Embodiment 2: A large-scale anaerobic fermentation process of straw, which is carried out using the device of embodiment 1, and the steps are as follows:

[0041] (1) Straw pretreatment

[0042] White rot fungi is added to the straw, stacked for 5 days, and naturally fermented to obtain biologically treated straw.

[0043] (2) Anaerobic fermentation

[0044] Crush the biologically treated straw in step (1) to 4-5mm, put it into tank 1, send it to anaerobic generator 4 by pump 3, distribute uniformly by distributing device 6, and stir and react for 7 days at a temperature of 53±1℃ . The obtained biogas is stored in the anaerobic generator 4, and there is a rubber storage airbag 5 on the top. The biogas residue liquid containing bacteria enters the next step of anaerobic bacteria separation.

[0045] In this step, the pH meter is set to 7.2±0.1, and the redox potentiometer is set to -150~400.

[0046] (3) Separation

[0047] The biogas residue liquid containing bacteria obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com