Method for processing steel plate with colorful coating layer and transfer device used by the method

A processing method and a technology of color coating, which are applied to the device for coating liquid on the surface, printing device, coating, etc., can solve the problems that have not been seen before

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

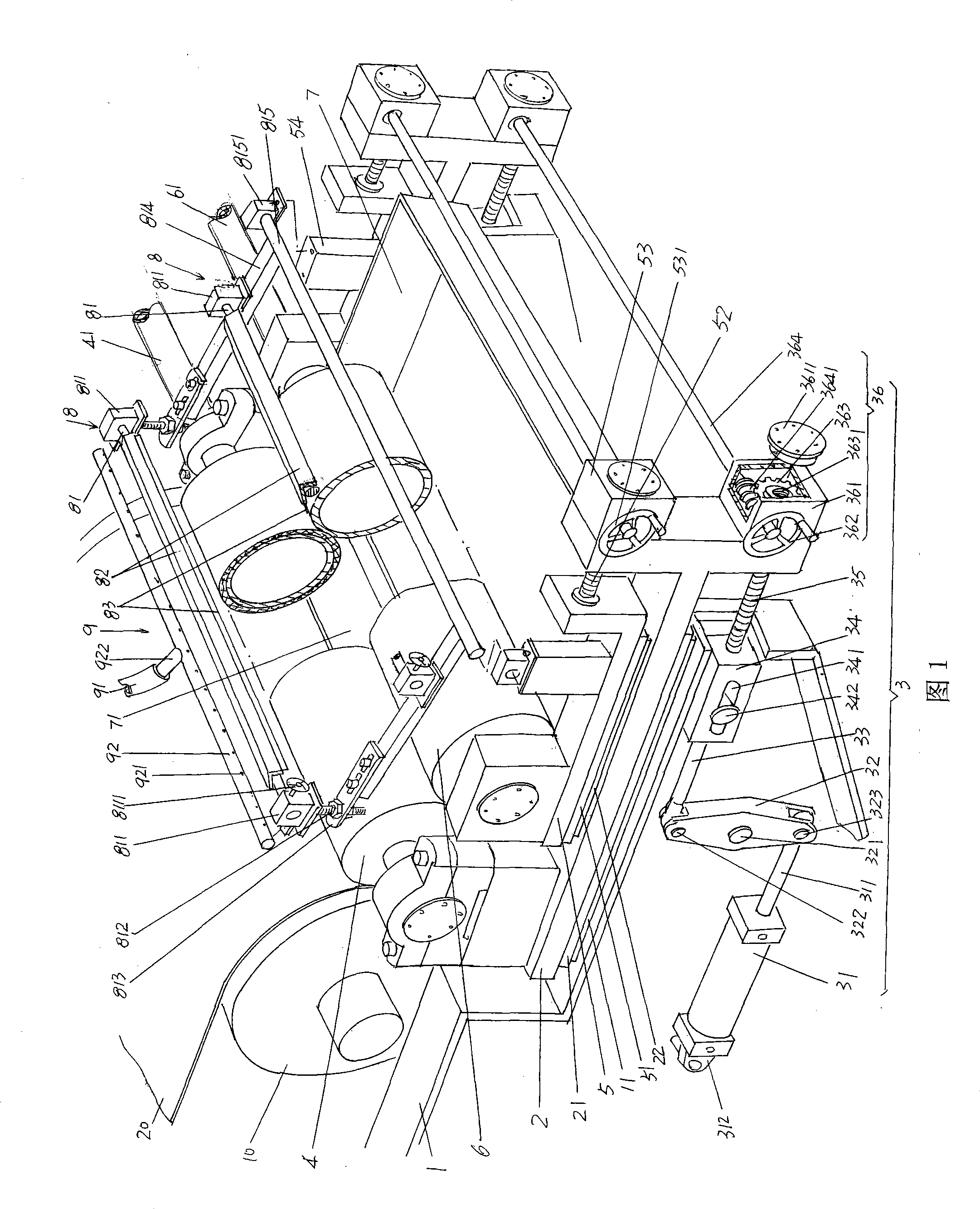

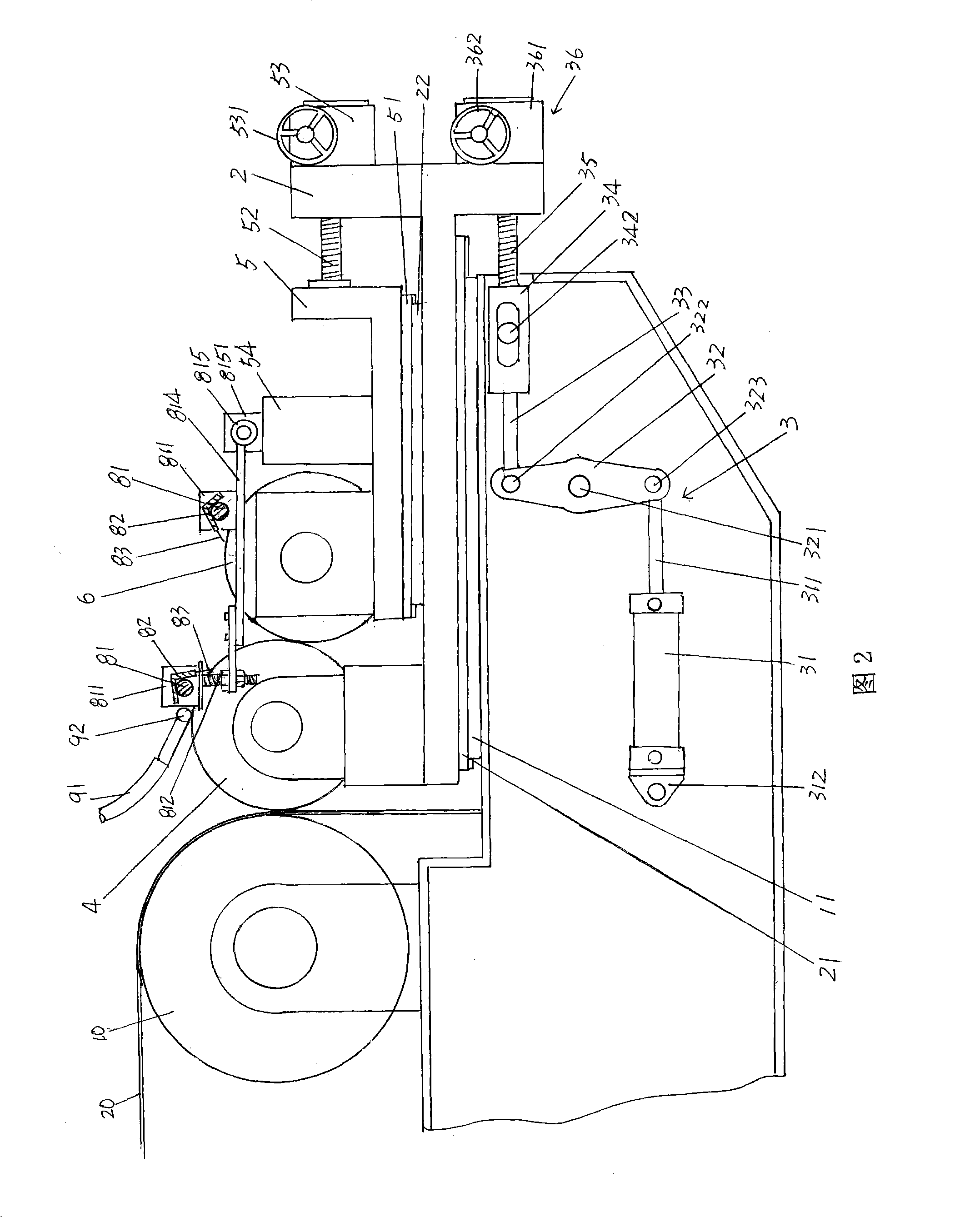

[0034] Take the processing of the steel plate 20 with two different colors as an example.

[0035] A) Uncoiling the galvanized steel sheet, specifically opening the previously coiled galvanized steel sheet;

[0036] B) Pretreatment, chemical treatment is carried out on the galvanized steel sheet after uncoiling. Specifically, the galvanized steel sheet is first introduced into a chemical cleaning tank to wash away the dust, marks and even oil stains remaining on the surface of the galvanized steel sheet, so that the galvanized steel sheet The surface of the galvanized steel is fully cleaned, and then dried after cleaning. The drying temperature is from room temperature to 60°C. If the galvanized steel sheet travels fast, the drying temperature will increase accordingly, and vice versa. Usually, the galvanized steel sheet 20 is controlled. The speed is 35-60m / min, 35m / min is selected in this embodiment, and then passivation treatment is carried out. The mechanism of passivation...

Embodiment 2

[0043] Only change the traveling speed of the galvanized steel sheet in step B) to 60m / min, the passivation temperature is 135°C, and the steel sheet temperature is 70°C; change the baking temperature in step D) to 320°C, and the temperature of the steel sheet is 20°C at 225°C, the traveling speed of the steel plate 20 is changed to 60m / min; the number of transfers in step E) is changed to three times, that is, three sets of transfer printing devices of the present invention are arranged on the traveling channel of the steel plate 20, and each transfer After printing, the temperature of entering the baking furnace for baking is changed to 50°C, and the advancing speed of the steel plate 20 is changed to 60m / min to obtain a color coated steel sheet blank with three colors or patterns; the baking in step F) The temperature was changed to 300° C., the traveling speed of the steel plate 20 was changed to 60 m / min, and the rest were the same as described in Example 1 to obtain a col...

Embodiment 3

[0045] Only change the traveling speed of the galvanized steel sheet in step B) to 55m / min, the passivation temperature is 120°C, and the steel sheet temperature is 62°C; change the baking temperature in step D) to 410°C, and the temperature of the steel sheet is 20°C at 240°C, the advancing speed of the steel plate 20 is changed to 55m / min; the number of transfers in step E) is changed to four times, that is, four sets of transfer printing devices of the present invention are set on the advancing channel of the steel plate 20, and each time After transfer printing, the baking temperature in the baking oven is changed to 60°C, and the traveling speed of the steel plate 20 is changed to 55m / min; the baking temperature in step F) is changed to 405°C, and the traveling speed of the steel plate 20 is changed to 55m / min , and the rest are the same as those described in Example 1 to obtain a color-coated steel sheet with four sets of colors or four sets of patterns on one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com