Coating composition of colorful material, colorful material and preparation method thereof

A coating composition and dazzling technology, which can be applied to devices for coating liquids on surfaces, coatings, pretreated surfaces, etc., can solve the problems of limited practical application, poor adhesion, low mechanical strength of coatings, etc. Excellent practicability, high production efficiency, and the effect of lowering the application threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

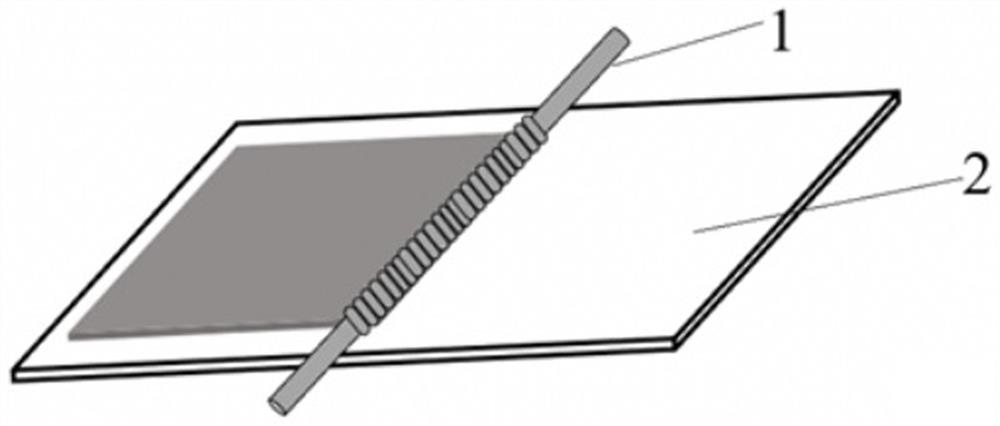

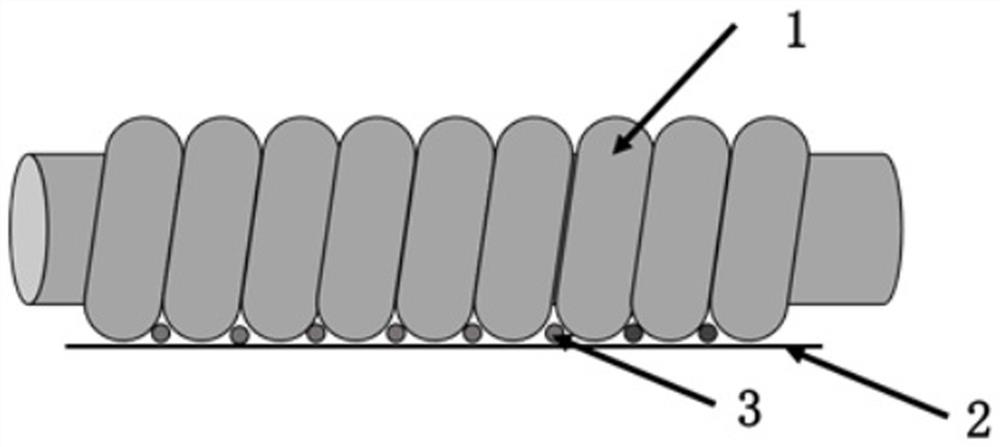

[0096] The schematic flow chart of the preparation method of colorful material of the present invention is as figure 1 , 2 Shown, the preparation method of colorful material comprises the steps:

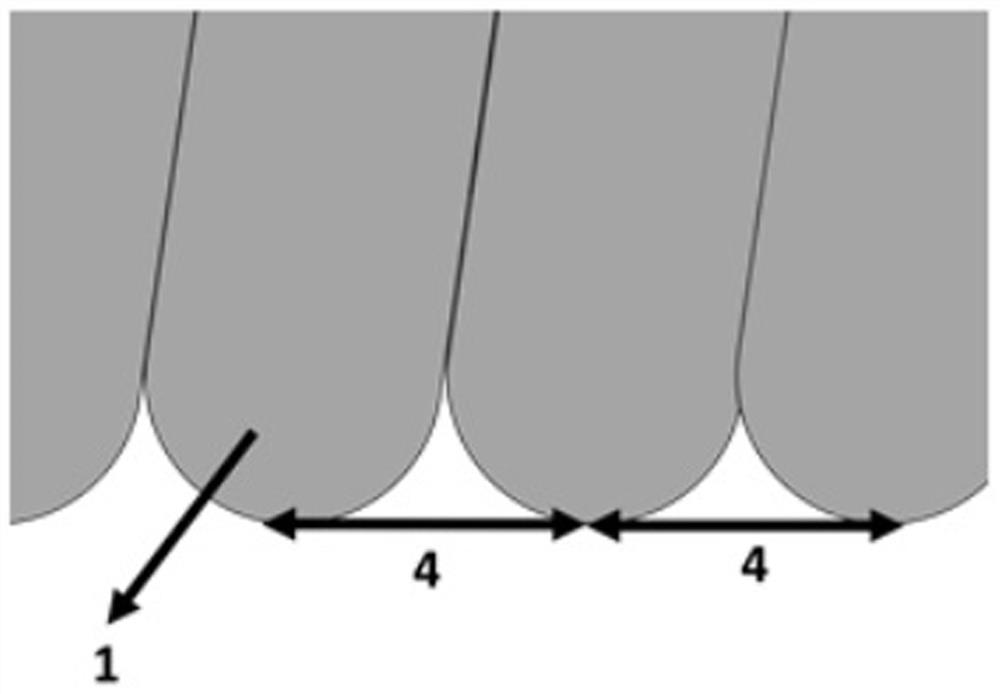

[0097] 1) The coating composition A is coated on the substrate 2 through the wire rod 1, and the periodically arranged gaps (pitch 4) between the wire rods are used to pass through the periodically arranged gaps when the nanospheres 3 are coated , after the solvent is completely dried and volatilized, the nanospheres 3 form a regular and periodic arrangement on the surface of the polymer substrate;

[0098] 2) Coat the coating composition B on the coating substrate 7, dry until the solvent is completely volatilized, and attach the coating composition A coating surface 6 obtained in step 1) to form the coating composition B coating surface 8. The coating surface 6 of the coating composition A is bonded to the coating surface 8 of the coating composition B, and UV curing is carried o...

Embodiment 1

[0100] Coating composition A includes: 5 parts of nanospheres (JNS-PC01-100, diameter 100 nm), 0.01 part of dispersant Anti-Terra-203, 0.05 part of leveling agent FS-3100, adding water to make coating The total solid content of the composition is 5 wt%, and it is stirred and mixed evenly. Coating composition A prepared above was evenly coated on PET film (thickness 50 μm) with a wire rod (wet thickness 20 μm, pitch 1 μm), and the coating dry thickness was 1 μm to complete the periodicity of the nanostructure. Arranged neatly; then dried at 100°C for 2 minutes. Coating composition B includes: 10 parts of trimethylolpropane triacrylate (SR351 NS), 0.5 parts of photoinitiator Irgacure 184, 1 part of adhesion promoter Silquest A-1170, leveling agent FS- 3100 is 1 part, add water to make the total solid content of the coating composition 30 wt%, stir and mix evenly. Coating composition B prepared above was uniformly coated on PET film (thickness 100 μm) with a doctor blade, the c...

Embodiment 2

[0102] Coating composition A includes: 10 parts of nanospheres (JNS-PC01-150, diameter 150 nm), 1 part of dispersant Anti-Terra-205, 2 parts of leveling agent FS-3100, adding water to make coating The total solid content of the composition is 10 wt%, and it is stirred and mixed evenly. Coating composition A prepared above was evenly coated on PET film (thickness 100 μm) with a wire rod (wet thickness 50 μm, pitch 5 μm), and the coating dry thickness was 5 μm to complete the periodicity of the nanostructure. Arranged neatly; then dried at 100°C for 2 minutes. Coating composition B includes: 20 parts of trimethylolpropane triacrylate (SR351 NS), 1 part of photoinitiator Irgacure 184, 2 parts of adhesion promoter CoatOSil MP 200, leveling agent FS-3100 For 2 parts, add isopropanol to make the total solid content of the coating composition 30 wt%, stir and mix evenly. The above-prepared coating composition B was uniformly coated on the PC film (thickness 100 μm) with a spatula t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com