Construction method for tunnel continuous mucking, lining and excavation synchronization

A tunnel and lining technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of infeasibility and practical application, and achieve the effect of shortening the tunnel construction period and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method of the present invention is described in conjunction with accompanying drawing, but does not form any restriction to the present invention:

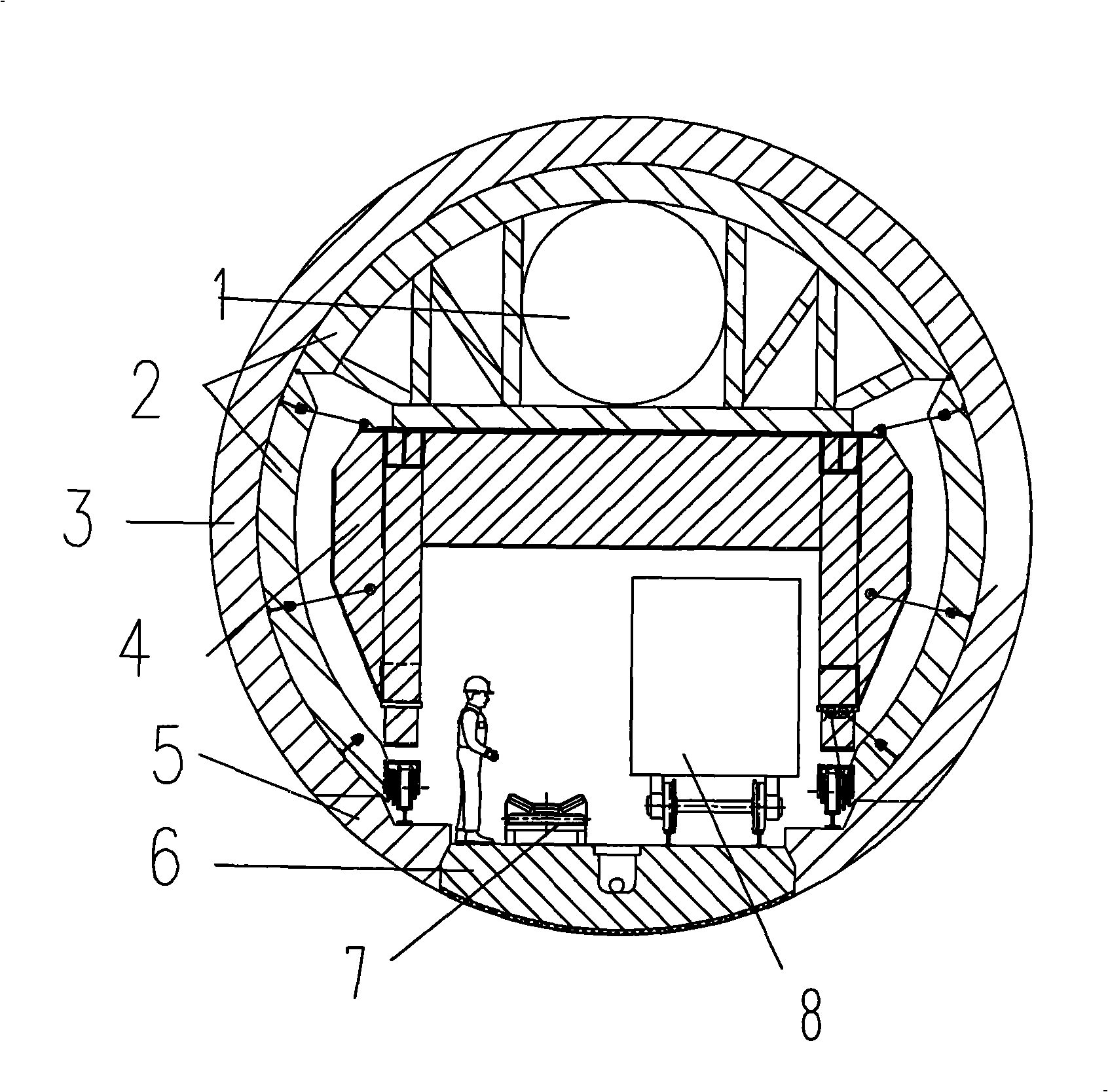

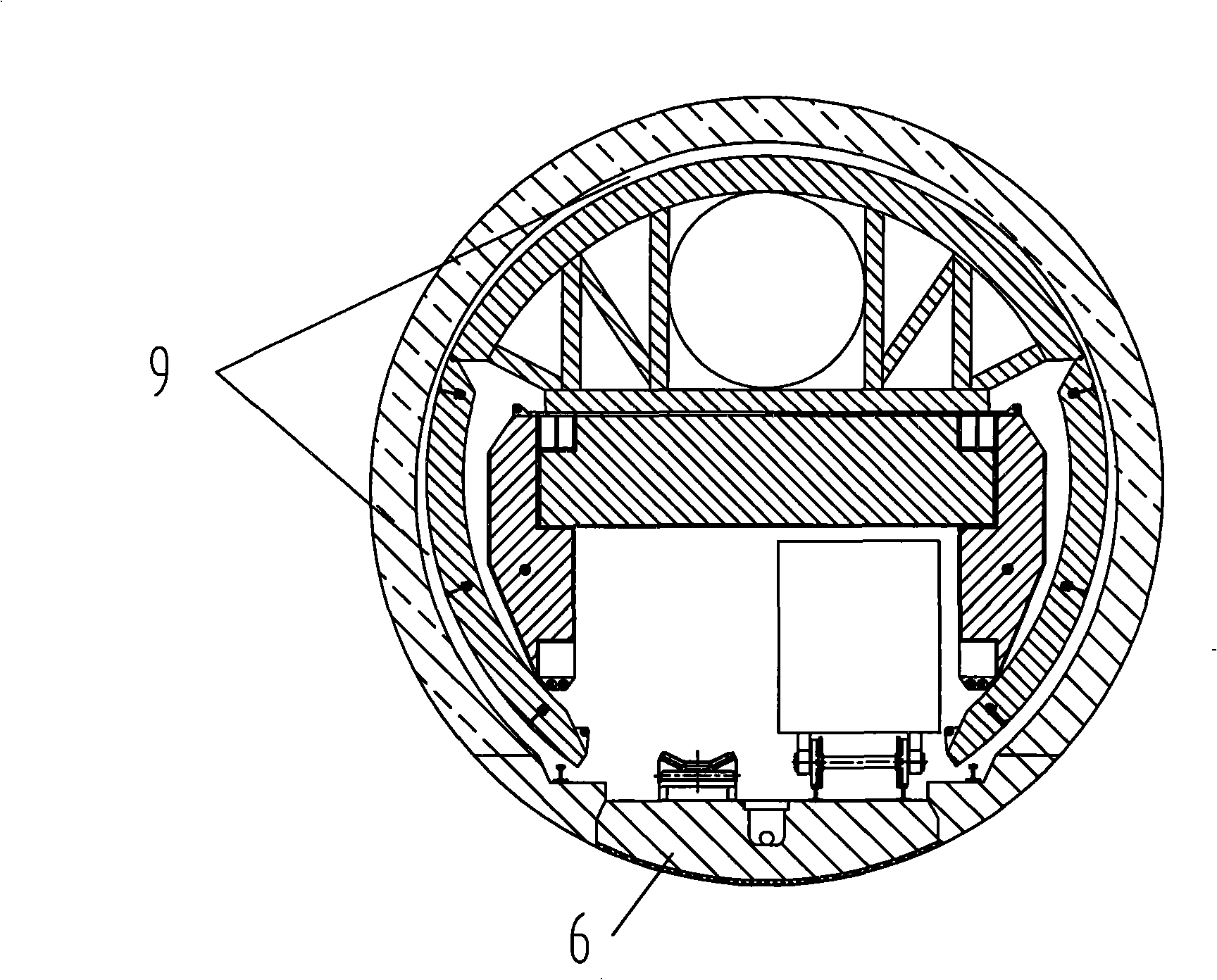

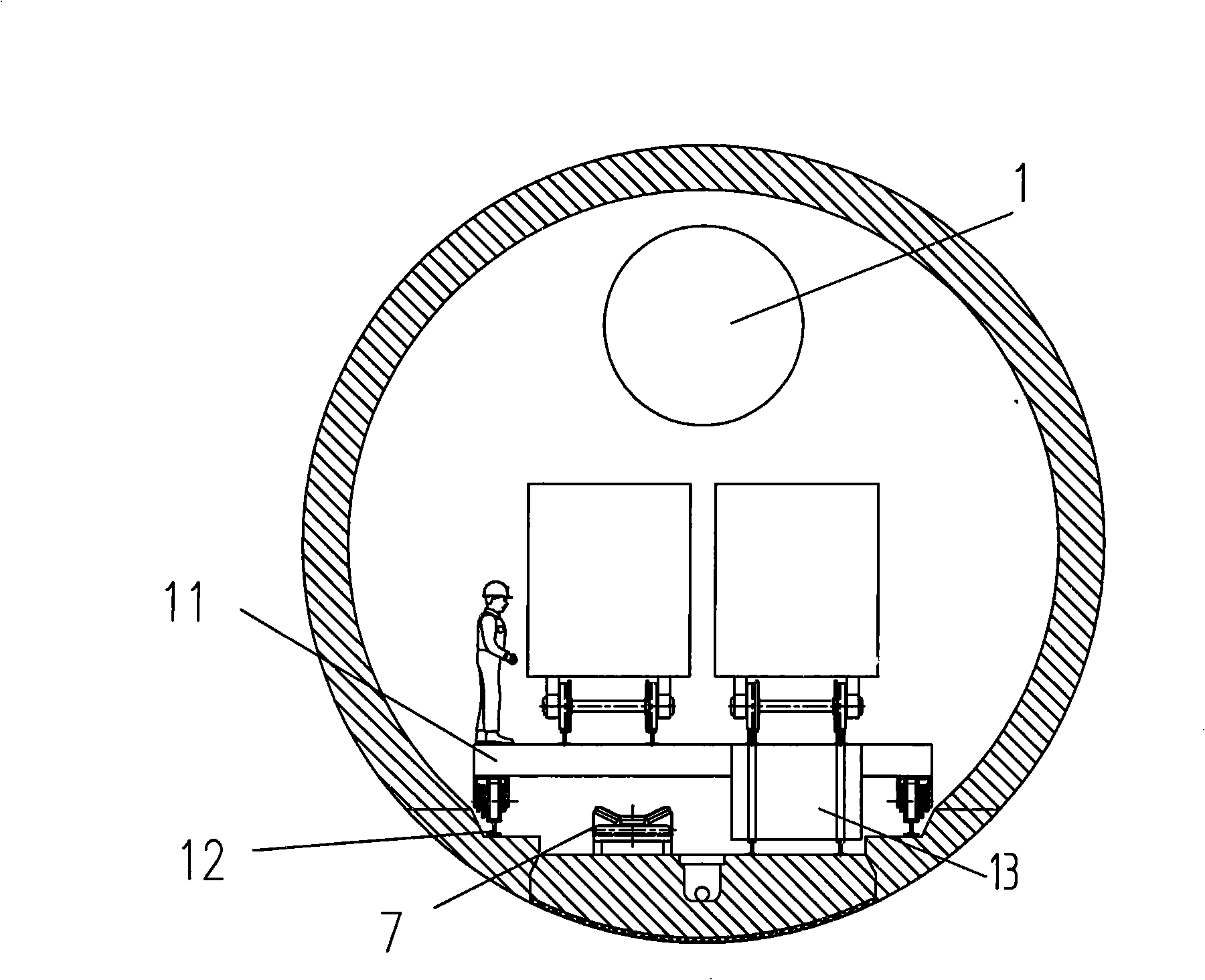

[0031] Such as figure 1As shown, the excavation of the TBM method tunnel is a circular section, and the prefabricated inverted arch block 6 is laid at the bottom of the tunnel inside the TBM equipment. Behind the TBM equipment, side wall foundations 5 are artificially poured on both sides of the inverted arch block. Lay the track 12 connected before the steel formwork trolley for the steel formwork trolley to travel. For the permanent support of the tunnel, the left side of the steel formwork trolley mast 4 is a long-distance continuous belt conveyor 7, which continuously transports the waste dregs excavated by the TBM cutter head outward, and the right side of the mast is an auxiliary transportation track for Rail transport machinery transports construction facilities and materials, and can also be used as a channel f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com