Production technology for T-shaped screen cloth

A production process and warping technology, which is applied in the field of polyester fabric processing, can solve the problems of warp and weft bending, poor machinability in the back channel, easy tearing, etc., and achieves the effect of small warp and weft shrinkage, improving production efficiency, and facilitating rolling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

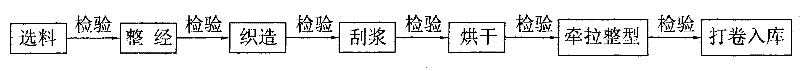

[0013] Embodiment one: the process of producing T-shaped cloth or large mesh cloth base cloth

[0014] First of all, the raw materials have passed the inspection and are put into the warehouse. The raw material warehouse requires drying, ventilation, and humidity less than or equal to 80%. The raw material is polyester filament. The strength is greater than or equal to 3.8cN / dtex, the coefficient of variation of the breaking strength is less than or equal to 5.0%, the elongation at break is 24% to 32%, the coefficient of variation of the elongation at break is less than or equal to 12.0%, and the degree of network is 2 to 12 per meter. The boiling water shrinkage rate is 6% to 8%, and the oil content is 0.3% to 1.3%.

[0015] Followed by warping, the warping workshop requires constant temperature and humidity. Silk plate porcelain eye, yarn dividing needle, tension roller, wool meter, yarn dividing needle, storage yarn dividing needle, oiler, herringbone reed dividing needle,...

Embodiment 2

[0019] Embodiment two: the technique of producing green mesh cloth or small mesh cloth:

[0020] This embodiment is all the same as Embodiment 1 in material selection, warping and weaving process, just add specific dyestuff when finalizing and squeegeeing, preheating setting machine oven, batching according to technological requirement: resin, catalyst, dyestuff A, Dye B, dye ℃, degreaser and water are mixed and stirred according to a specific ratio, and put into the slurry tank after stirring evenly. While preparing the slurry, place the base fabric that needs to be shaped on the unwinding machine, install the winding paper tube at the winding place, and guide the base fabric to the slurry slot with the pre-prepared guide cloth. After the oven temperature reaches the specified requirements, Start production, the base fabric passes through the slurry tank for sizing, and then passes through the roller with an air pressure of 0.5KG. During the process of unwinding and sizing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com