Surface crack renovation method for key elements of chain grate

A repairing method and a technology for surface cracks, which are applied in the coating process of metal materials, coatings, etc., can solve the problems of cumbersome process, unfavorable real-time operation, long processing time, etc. The effect of little damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

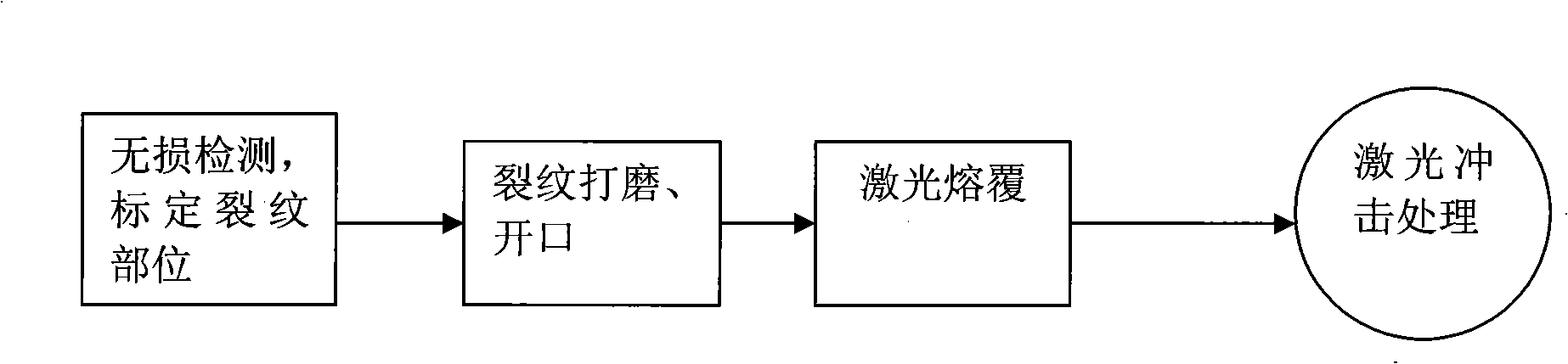

[0023] Embodiment: select the small shaft of the grate machine to do the surface crack repair test, the repair process is as follows figure 1 shown. Experimental material: 12CrMoV. Firstly, detect surface cracks on the surface of the small shaft of the grate, install two eddy current sensors on the surface of the tested workpiece, and determine the specific part of the crack on the surface of the part through the detected sensor signal, and determine the laser cladding treatment part.

[0024] Broadband laser cladding test using NEL-2000A fast axial flow industrial CO 2 Laser, the laser output beam is a multi-order mode, the output power is 2500W, the scanning speed is 2mm / s, the spot size is 15mm×2mm, the focal length is 315mm, the powder is preset on the surface of the substrate, and the thickness is about 115mm. A single scan is performed on the surface, and the thickness of the formed cladding layer is about 1 mm. The sample is cut in the direction perpendicular to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com