Nitridation apparatus and process for cast iron piston ring

A cast iron piston and piston ring technology, applied in metal material coating process, coating, solid diffusion coating, etc., can solve the problems that the product is difficult to meet customer requirements, the nitriding process of cast iron piston ring, and the process are not well understood. Achieve the effect of meeting market demand, low production cost and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

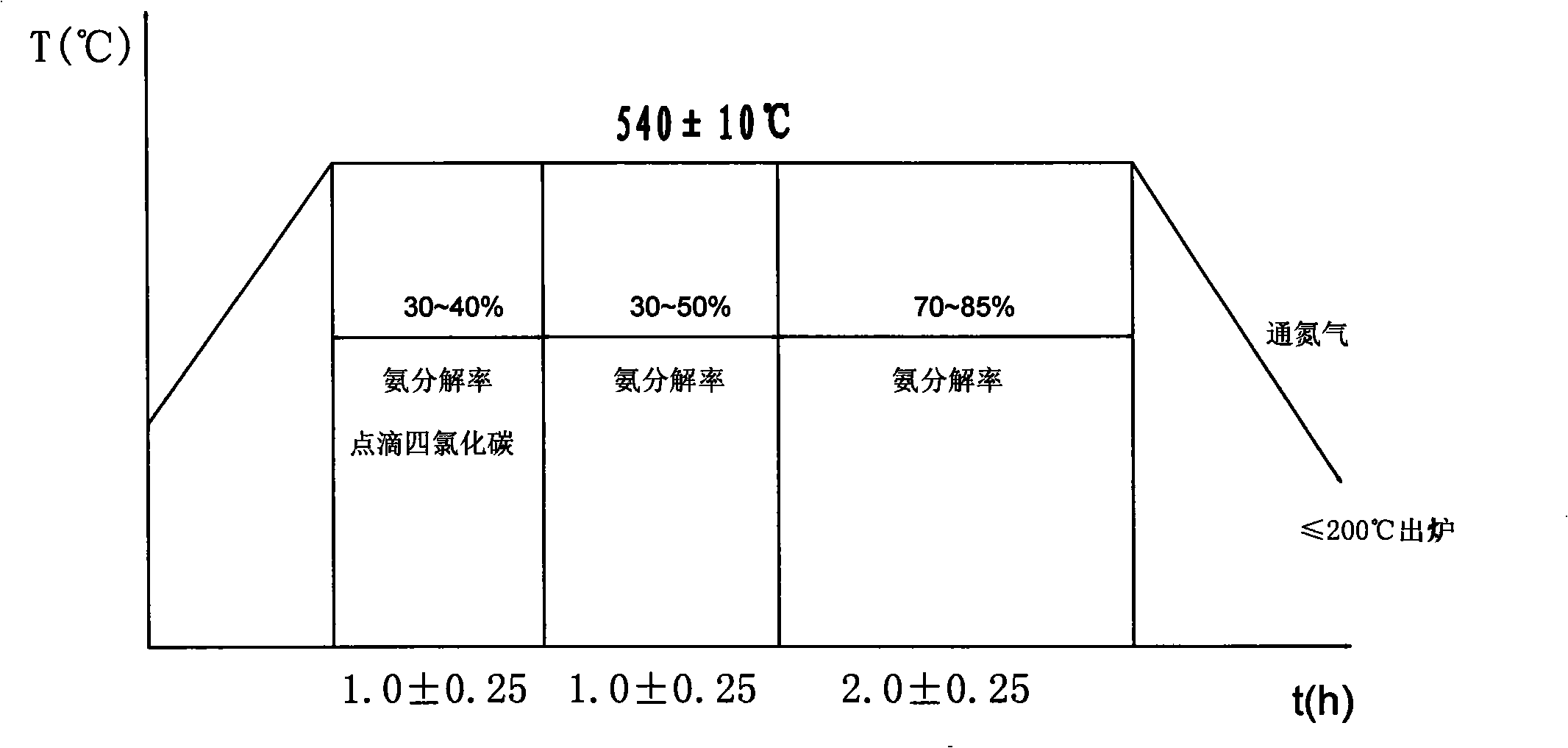

[0054] Nitriding process is:

[0055] (3) Preparations before nitriding: cleaning, drying, pickling, cleaning and drying;

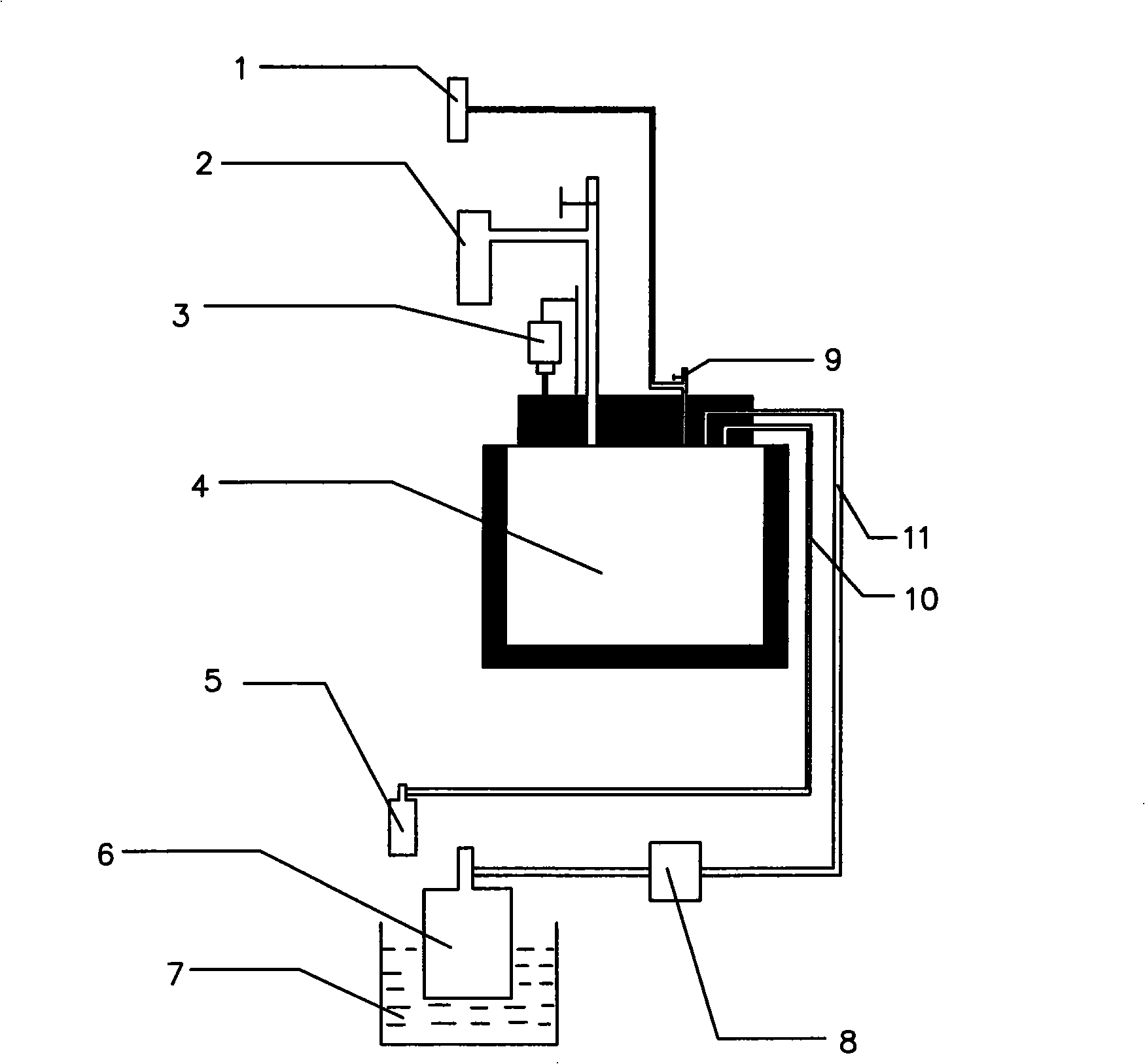

[0056] (4) Nitriding, using an industrial nitriding furnace, using gas nitriding:

[0057] A. Preparation stage:

[0058] a) Check whether ammonia gas, nitrogen gas and desiccant are sufficient;

[0059] b) Clean the furnace, furnace cover and hangers, dredge the pipeline and confirm that the pipeline is unimpeded;

[0060] c) Hang the pickled, oil-free and water-stained ring flat and tightly on the hanger with the opening facing upwards;

[0061] d) Slowly hang the hanging ring into the furnace;

[0062] e) Apply a layer of silica gel and clay mixture on the sealing ring, cover the furnace cover and tighten the bolts;

[0063] f) Insert the thermocouple and connect the ammonia gas and waste gas pipelines;

[0064] g) Adjust the position where the exhaust gas enters the water so that the pressure in the furnace is 600mm water column;

[0065] B. He...

Embodiment 2

[0078] Nitriding process is:

[0079] (1) Preparations before nitriding: cleaning, drying, pickling, cleaning and drying;

[0080] (2) Nitriding, using industrial nitriding furnace, using gas nitriding:

[0081] A. Preparation stage:

[0082] a) Check whether ammonia gas, nitrogen gas and desiccant are sufficient;

[0083] b) Clean the furnace, furnace cover and hangers, dredge the pipeline and confirm that the pipeline is unimpeded;

[0084] c) Hang the pickled, oil-free and water-stained ring flat and tightly on the hanger with the opening facing upwards;

[0085] d) Slowly hang the hanging ring into the furnace;

[0086] e) Apply a layer of silica gel and clay mixture on the sealing ring, cover the furnace cover and tighten the bolts;

[0087] f) Insert the thermocouple and connect the ammonia gas and waste gas pipelines;

[0088] g) Adjust the waste gas inlet position so that the pressure in the furnace is 700mm water column;

[0089] B. Heating stage:

[0090] a) ...

Embodiment 3

[0102] Nitriding process is:

[0103] (3) Preparations before nitriding: cleaning, drying, pickling, cleaning and drying;

[0104] (4) Nitriding, using an industrial nitriding furnace, using gas nitriding:

[0105] A. Preparation stage:

[0106] a) Check whether ammonia gas, nitrogen gas and desiccant are sufficient;

[0107] b) Clean the furnace, furnace cover and hangers, dredge the pipeline and confirm that the pipeline is unimpeded;

[0108] c) Hang the pickled, oil-free and water-stained ring flat and tightly on the hanger with the opening facing upwards;

[0109] d) Slowly hang the hanging ring into the furnace;

[0110] e) Apply a layer of silica gel and clay mixture on the sealing ring, cover the furnace cover and tighten the bolts;

[0111] f) Insert the thermocouple and connect the ammonia gas and waste gas pipelines;

[0112] g) Adjust the waste gas inlet position so that the pressure in the furnace is 650mm water column;

[0113] B. Heating stage:

[0114] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com