Single-substrate single-doping lanthanum aluminate full-color adjustable fluorinite and production method thereof

A phosphor, lanthanum aluminate technology, used in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problem of low color rendering of white light, inconsistent light decay and efficiency of absorption, excitation and emission spectra, and weak fluorescence And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

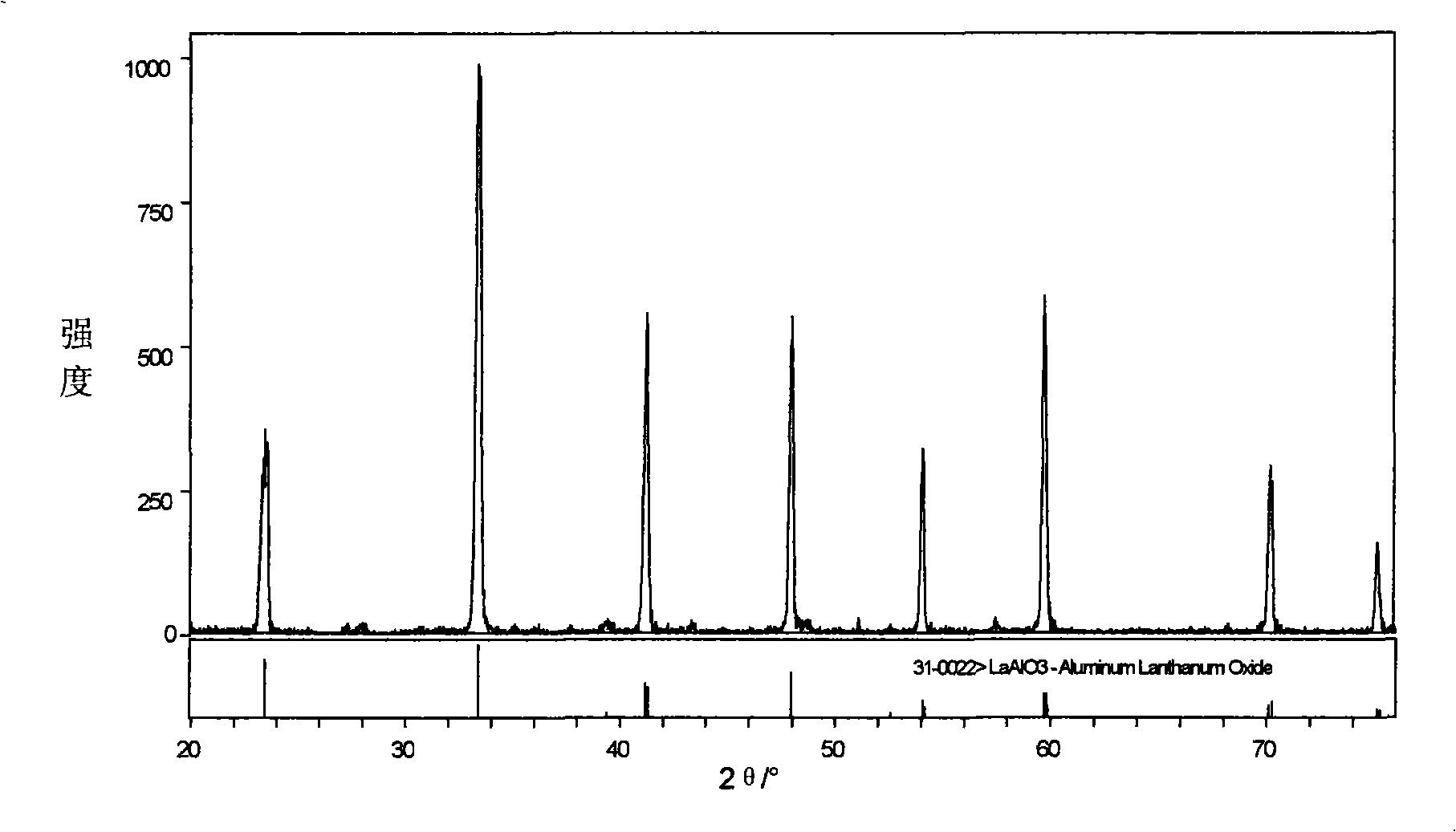

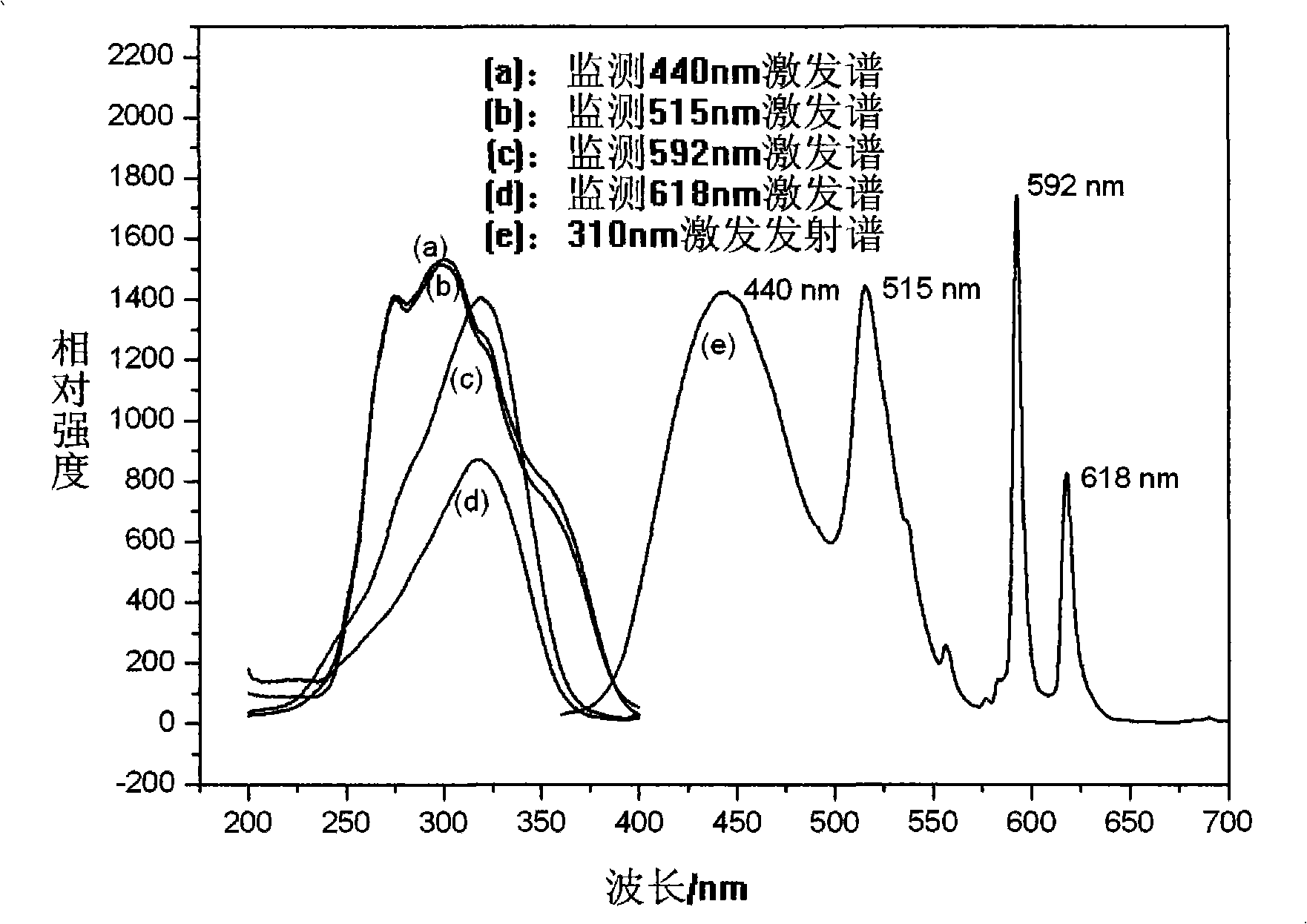

[0029] According to the chemical formula of the phosphor La 1-a AlO 3 :Eu a , Li + b (a=0.02, b=0.00), the weighed raw materials (3.1933gLa 2 o 3 , 1.0196gAl 2 o 3 , 0.0704gEu 2 o 3 ) was dissolved in alcohol to form a slurry; the slurry was oscillated in an ultrasonic wave for 10 minutes and then dried at 50°C. The resulting powder was in H 2 The ratio is 8% N 2 +H 2 Burn in a horizontal tube furnace at 1400°C for 4 hours in a mixed reducing atmosphere. attached figure 1 Be the X-ray diffraction figure of embodiment 1 product in the middle, appendix figure 2 is the emission spectrum and its excitation spectrum under the excitation of 310 nm wavelength light.

Embodiment 2

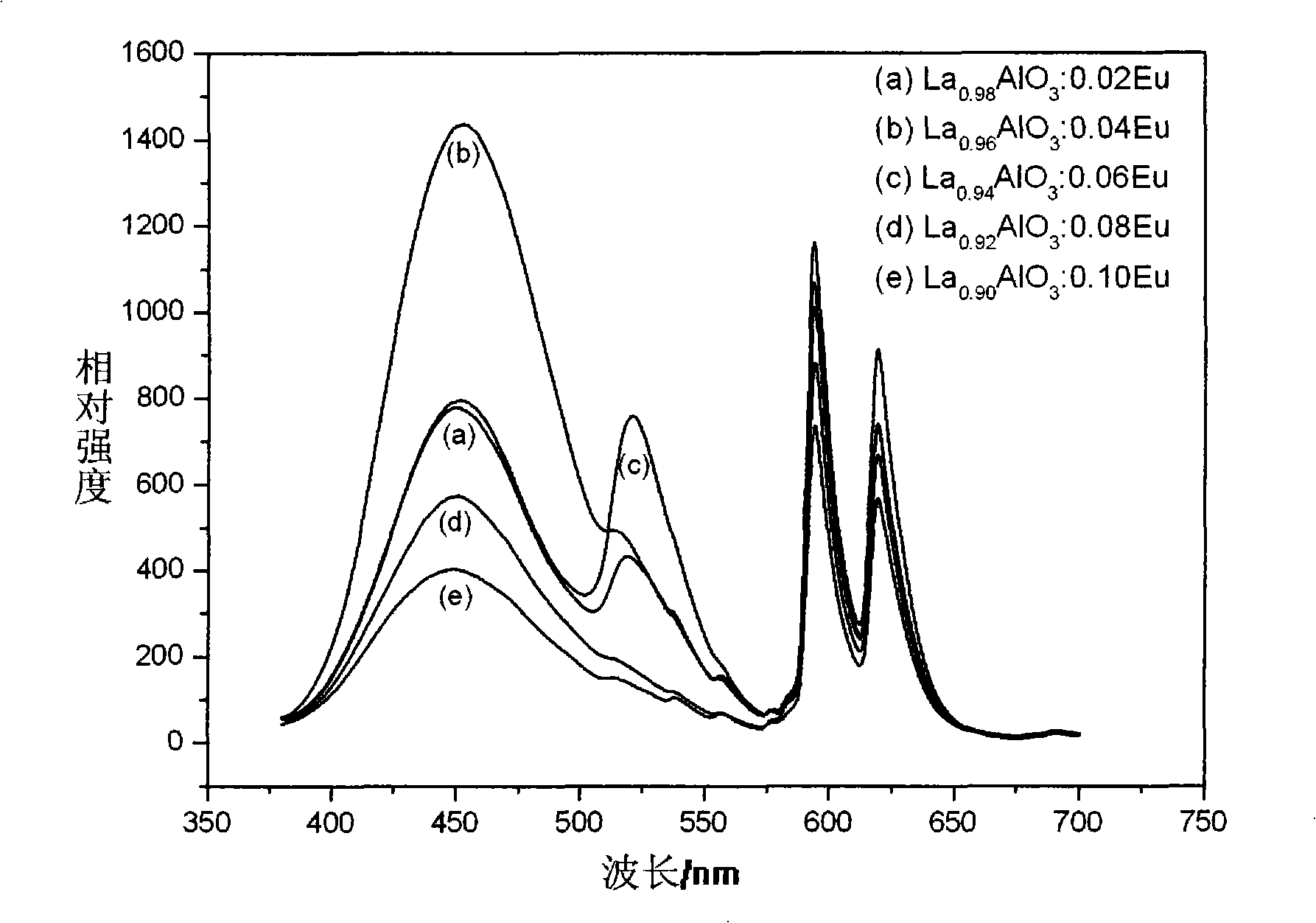

[0031] According to the chemical formula of the phosphor La 1-a AlO 3 :Eu a , Li + b (a=0.02, 0.04, 0.06, 0.08, 0.10, b=0.00), the weighed raw materials (a=-0.02, 3.1933gLa 2 o 3 , 1.0196gAl 2 o 3 , 0.0704gEu 2 o 3 ; a=0.04, 3.1282gLa 2 o 3 , 1.0196gAl 2 o 3 , 0.1408gEu 2 o 3 ; a=0.06, 3.0630gLa 2 o 3 , 1.0196gAl 2 o 3 , 0.2112gEu 2 o 3 ; a=0.08, 2.9978gLa 2 o 3 , 1.0196gAl 2 o 3 , 2816gEu 2 o 3 ; a=0.10, 2.9327gLa 2 o 3 , 1.0196gAl 2 o 3 , 0.3520gEu 2 o 3 ;) was dissolved in alcohol to form a serum; the serum was oscillated in an ultrasonic wave for 30 minutes and then dried at 70 degrees. The resulting powder was in H 2 The ratio is 8% N 2 +H 2 Burn in a horizontal tube furnace at 1400°C for 4 hours in a mixed reducing atmosphere. image 3 is the emission spectrum of Example 2.

Embodiment 3

[0033] According to the chemical formula of the phosphor La 1-a AlO 3 :Eu a , Li + b (a=0.04, b=0.00), the weighed raw material (3.1282gLa 2 o 3 , 1.0196g Al 2 o 3 , 0.1408gEu 2 o 3 ) was dissolved in alcohol to form a slurry; the slurry was oscillated in an ultrasonic wave for 50 minutes and then dried at 90°C. The resulting powder was in H 2 The ratio is 8% N 2 +H 2 Burn in a horizontal tube furnace at 1500°C, 1400°C, 1300°C, and 1200°C for 4 hours in a mixed reducing atmosphere. attached Figure 4 are the emission spectra at different firing temperatures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com