Sulfonation phenylphosphonic acid zirconium doping proton exchanging film and method of producing the same

A technology of sulfonated phenylphosphonic acid and proton exchange membrane, which is applied in electrochemical generators, fuel cell parts, fuel cells, etc. High temperature resistance, improved proton conductivity, and superior electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

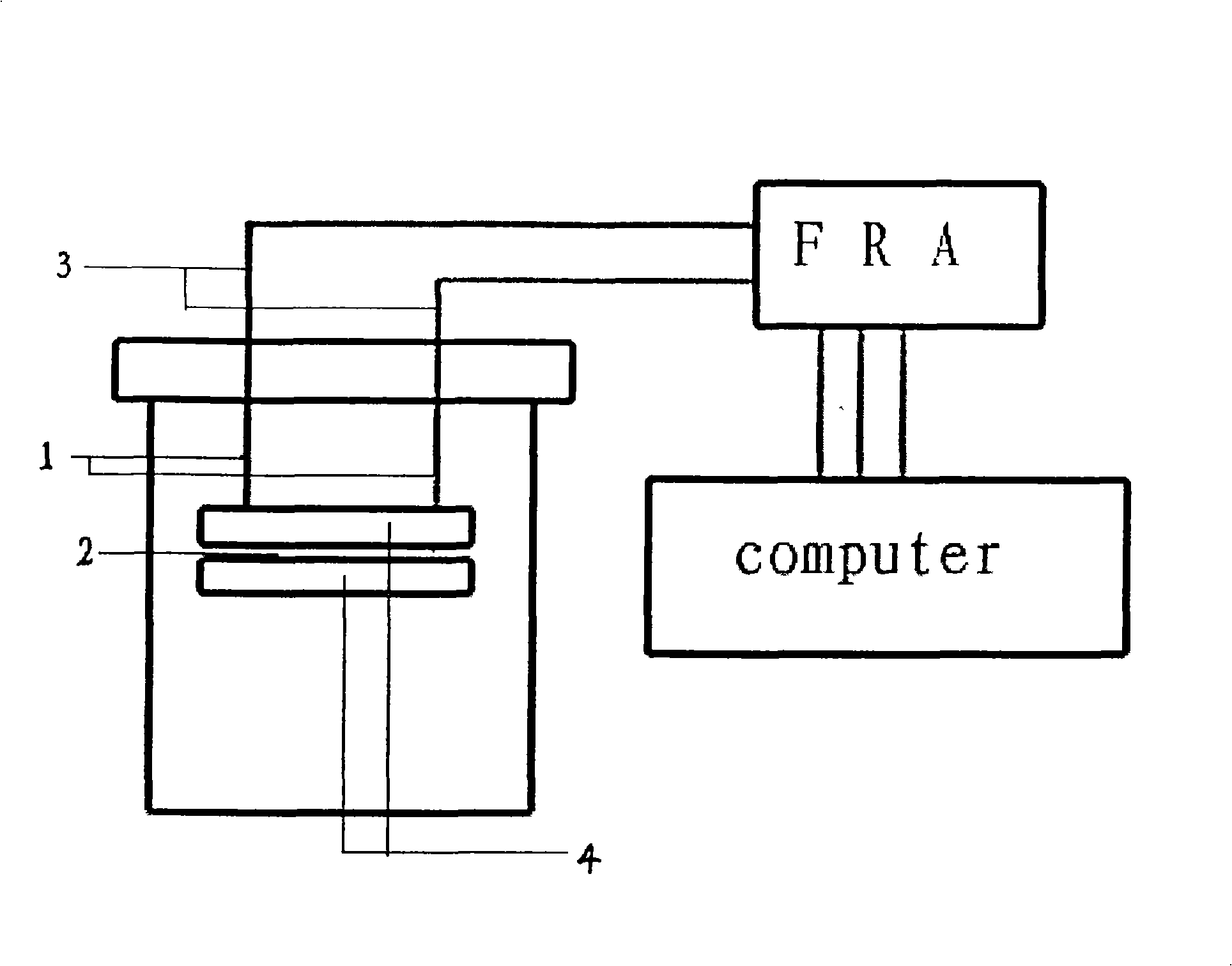

Image

Examples

Embodiment 1

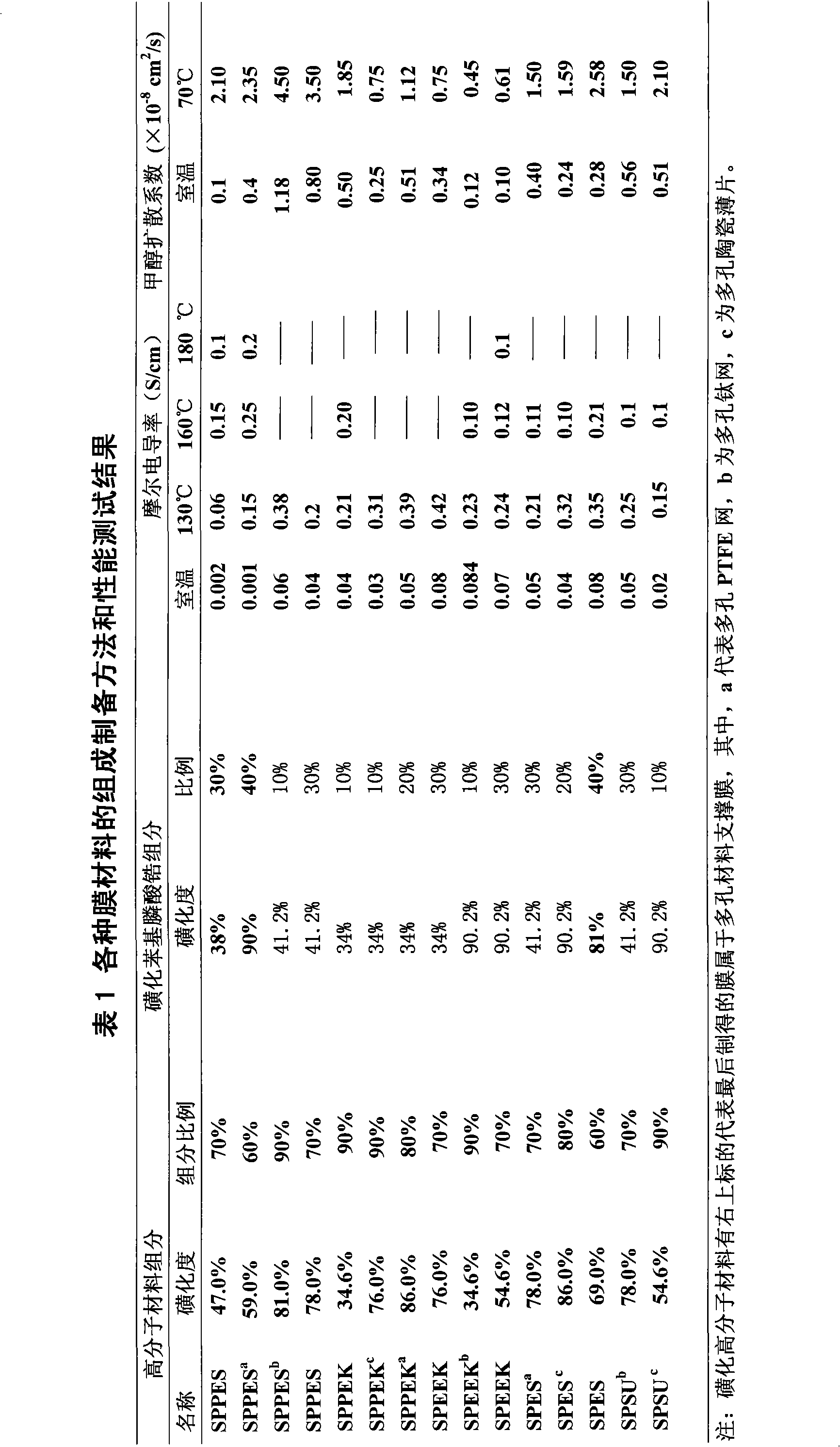

[0044] [Example 1]: Preparation of Sulfonated Polyphthalene Polyethersulfone (SPPES)

[0045] Add 3g of PPES to a three-necked flask equipped with an electric stirrer, a reflux condenser, and a dropping funnel, heat in a water bath, stir, and dropwise add a mixed solution of concentrated sulfuric acid and oleum to it, and finish adding dropwise within 10 to 30 minutes. Reflux and stir at 60°C to 80°C for 3 to 5 hours. After the reaction is complete, pour out the supernatant in the three-neck flask, pour the brown viscous liquid at the bottom into the ice-water mixture and spin to obtain a white filament. Wash with water until neutral (PH is about 7), and put it into a vacuum drying oven to dry for 24 hours. Take out and pulverize, wash with water until the pH is about 7, filter with suction, put the filter cake in a vacuum drying oven to dry for 24 hours, and pulverize to obtain a white powder. The degree of sulfonation (DS) was determined.

Embodiment 2

[0046] [Example 2]: sulfonated polynaphthalene polyether sulfone ketone (SPPEK), the preparation of sulfonated polynaphthalene polyether sulfone ketone (SPPESK) is the same as embodiment 1, just the raw material polynaphthalene polyether sulfone (SPPEK) PPES) can be replaced by polynaphthalene polyether ketone (PPEK) and polynaphthalene polyether sulfone ketone (PPESK) respectively.

Embodiment 3

[0047] [Example 3]: The preparation of sulfonated polyether ether ketone (SPEEK) and sulfonated polyether sulfone (SPES) is the same as in Example 1, except that the raw material polyether ether sulfone (PPES) is replaced by polyether ether For ketone (PEEK) and polyethersulfone (PES), just replace the sulfonating reagent with concentrated sulfuric acid.

[0048] The sulfonation of other materials is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com