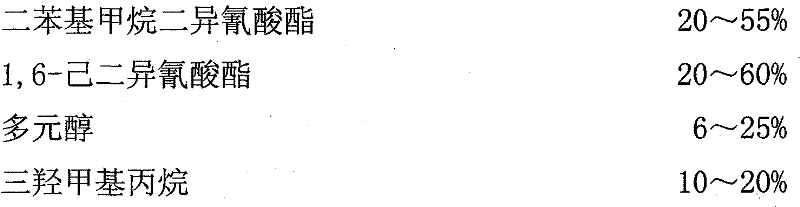

Mixed prepolymer of solidifying agent methyl diphenylene diisocyanate and 1,6-hexamethylene diisocyanate and its preparation method

A technology of hexamethylene diisocyanate and diphenylmethane, which is applied in the field of adhesive curing agent prepolymer and its preparation, polyurethane coatings, and can solve the problems of complex manufacturing process and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

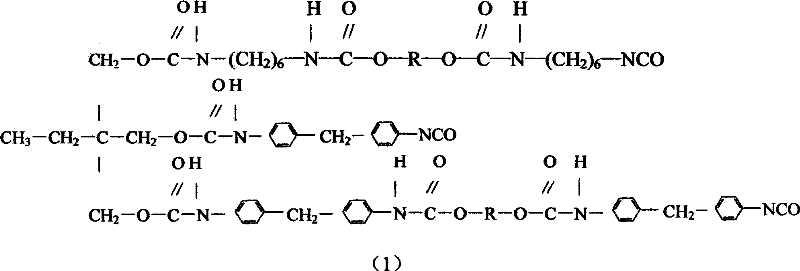

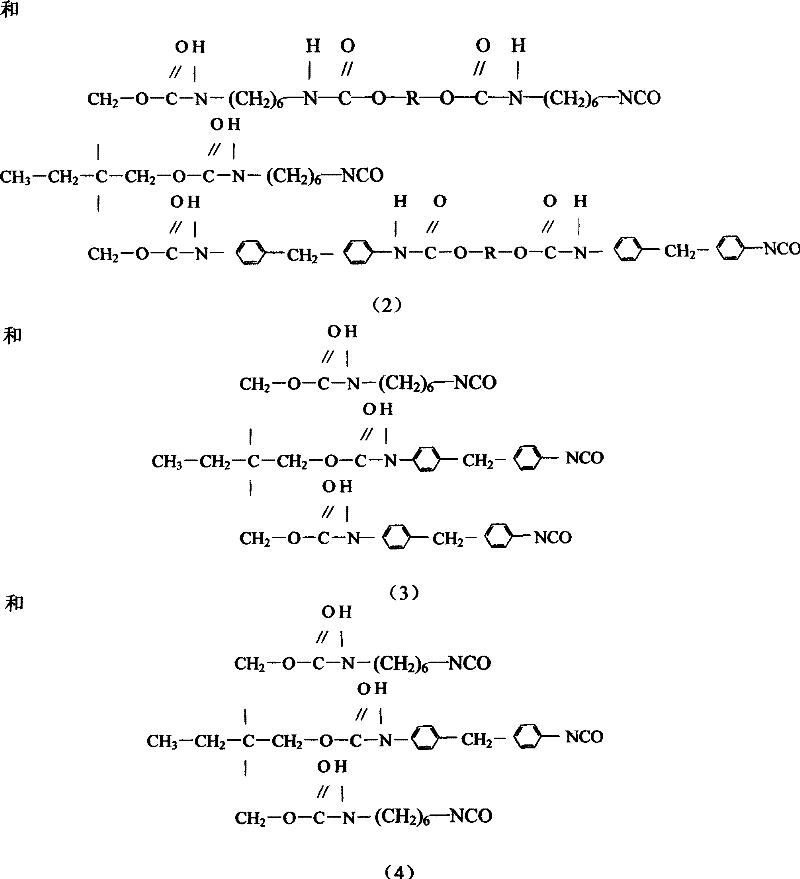

Method used

Image

Examples

Embodiment 1

[0054] a. Add 100 grams of molten MDI-100 and 100 grams of ethyl acetate in the No. 1 reaction kettle, stir evenly, heat up to 65°C, add 30 grams of polyε-caprolactone diol dehydrated by vacuum, at 65 React at ~75°C for 2 hours to obtain the modified MDI; b. Add 180 grams of HDI and 100 grams of ethyl acetate to the No. For ester diol, stir coldly at room temperature for 1.5 hours, raise the temperature to 70-80°C for 2 hours, and react for 1 hour at 85-90°C to obtain HDI modified products; lower the temperature of the material to below 70°C, add 57 A mixed solution composed of 1 gram of trimethylolpropane and 50 grams of ethyl acetate was reacted below 70°C for 3 hours, at 70-80°C for 2 hours, and at 85-95°C for 1 hour to obtain a HDI prepolymer; c , Then lower the temperature of the material in the No. 2 reactor to below 70°C, add the MDI modified product made in the No. 1 reactor, react at 70-80°C for 2 hours, react at 80-90°C for 1.5 hours, and cool down to 60°C; D, add 3...

Embodiment 2

[0059] a. Add 110 grams of melted MDI-100 and 60 grams of ethyl acetate into the No. 1 reaction kettle, stir evenly, heat up to 70°C, add 40 grams of polycarbonate diol that has been dehydrated in a vacuum, and heat it at 70-80°C React for 2 hours at 80-90°C for 1 hour to obtain a modified MDI; b. Add 250 grams of HDI and 60 grams of butanone to the No. 2 reactor, stir well, and add 80 grams of dehydrated MDI Polycarbonate diol, cold stirring at room temperature for 1 hour, heating up to 60-70°C for 2 hours, 80-90°C for 2.5 hours to obtain HDI modified products; lower the temperature of the material to below 70°C, Add a mixture of 64 grams of trimethylolpropane and 50 grams of ethyl acetate, react below 70°C for 2 hours, react at 70-75°C for 3 hours, and react at 80-90°C for 1 hour to obtain HDI prepolymer ; c, then lower the material temperature of the No. 2 reactor to below 70°C, add the MDI modified product made from the No. 1 kettle, react at 65-75°C for 3 hours, react at ...

Embodiment 3

[0062] a. Add 210 grams of melted MDI-100 and 80 grams of ethyl acetate into the No. 1 reactor, stir well, heat up to 75°C, add 60 grams of alkyd resin dehydrated by vacuum, and react at 70-80°C 1.5 hours, react at 85-95°C for 1 hour to obtain modified MDI; b. Add 90 grams of HDI and 30 grams of cyclohexanone into the No. 2 reaction kettle, stir evenly, and add 20 grams of alcohol dehydrated by vacuum Acid resin, cold stirring at room temperature for 0.5 hours, heated to 65-75°C for 2 hours, 80-90°C for 3 hours to obtain HDI modified product; lower the temperature of the material to below 70°C, add 48 grams A mixed solution composed of trimethylolpropane and 33 grams of ethyl acetate was reacted below 70°C for 4 hours, at 65-75°C for 1 hour, and at 80-90°C for 1 hour to obtain a HDI prepolymer; c, Then lower the material temperature of the No. 2 reactor to below 70°C, add the MDI prepolymer made from the No. 1 reactor, react at 65-75°C for 3 hours, react at 85-95°C for 1.5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com