Constant-water level CAST wastewater treatment method and system

A sewage treatment method and a sewage treatment system technology, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

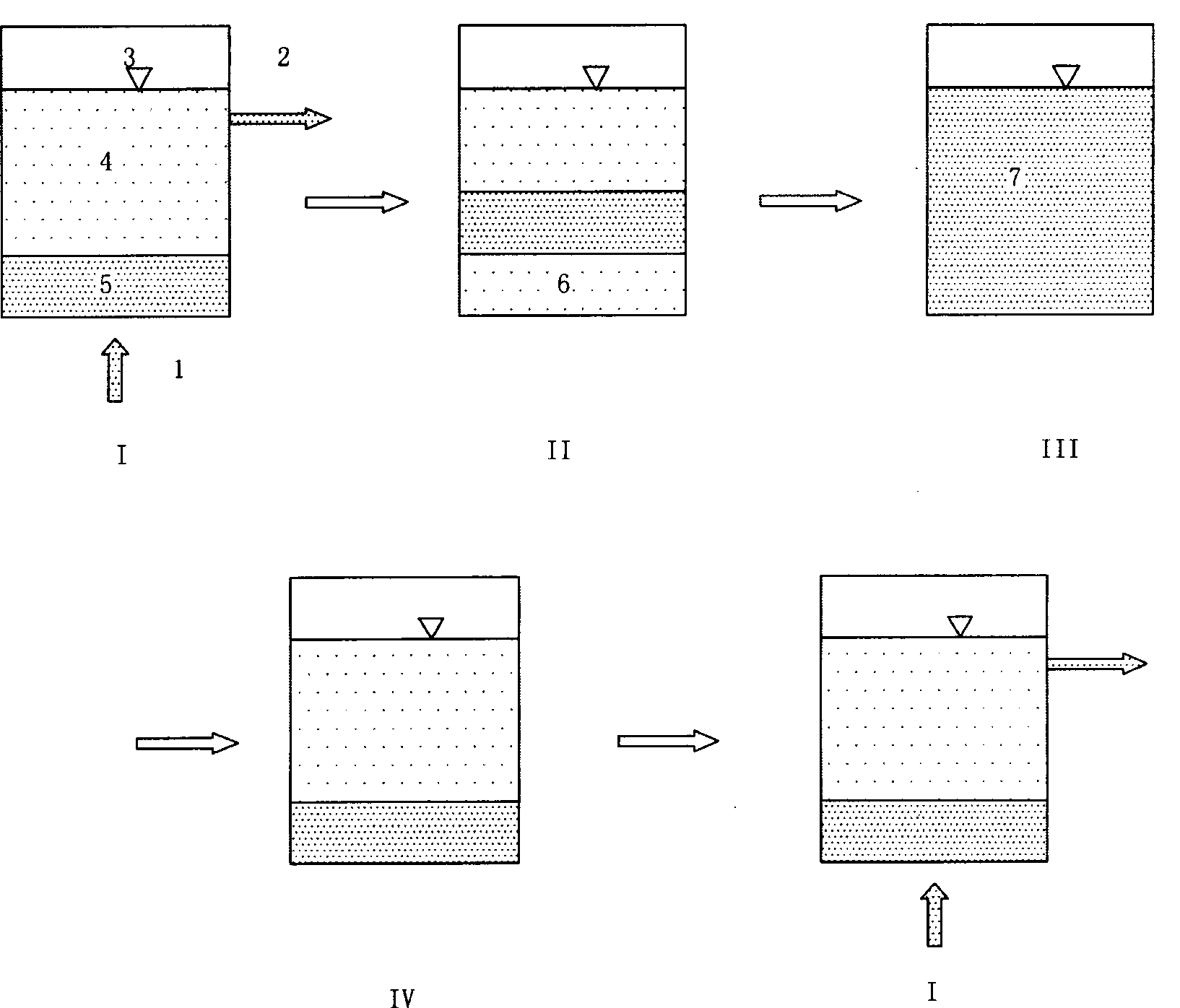

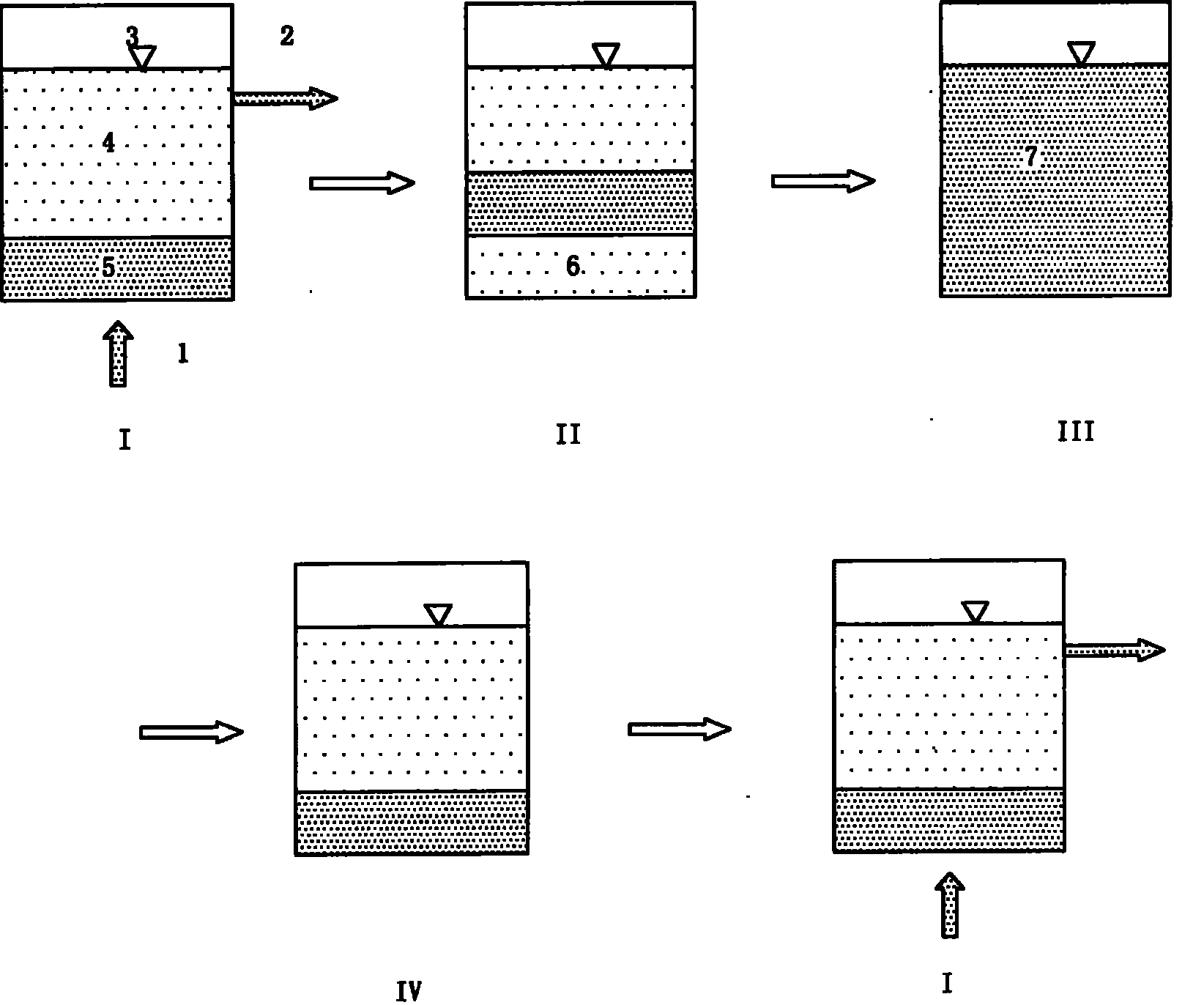

[0045] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0046] According to the designed water quantity, the raw sewage enters the CAST reaction tank, the blower is started for aeration, the organic matter in the water is removed aerobicly, and then the ammonia nitrogen in the water is oxidized to nitrate nitrogen for nitrification. The air bubbles generated in the aeration process make the sewage and activated sludge fully contact, and play the role of stirring and mixing. Activated sludge oxidation of organic matter and ammonia nitrogen in water is an aerobic process. Therefore, when the organic matter is completely degraded and the nitrification reaction is over, the dissolved oxygen in the water will no longer be used by microorganisms. Therefore, the DO (Dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com