Technique for producing slag runner ramming mix by using waste blast furnace runner material and blast furnace dust collecting powder

A technology of ramming material and blast furnace is applied in the field of regeneration of waste resources to achieve the effects of being beneficial to environmental protection, reducing production costs and novel production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Use 75% of the finished material of waste trench material with a particle size of 8-0mm as the aggregate, add 20% of the finished material fine powder of blast furnace dust collection powder with a particle size of ≤0.044mm, 5% of the first-grade soft clay fine powder with a particle size of ≤0.044mm and 0.02% of the modified additive with a particle size of ≤0.044mm is used as the base material, and 4.3% of the binder industrial syrup solution is added to each base material to obtain the slag ditch ramming material of the present invention.

[0046] In this formula, the added amount of recycled waste refractories and blast furnace dust powder reaches 90%.

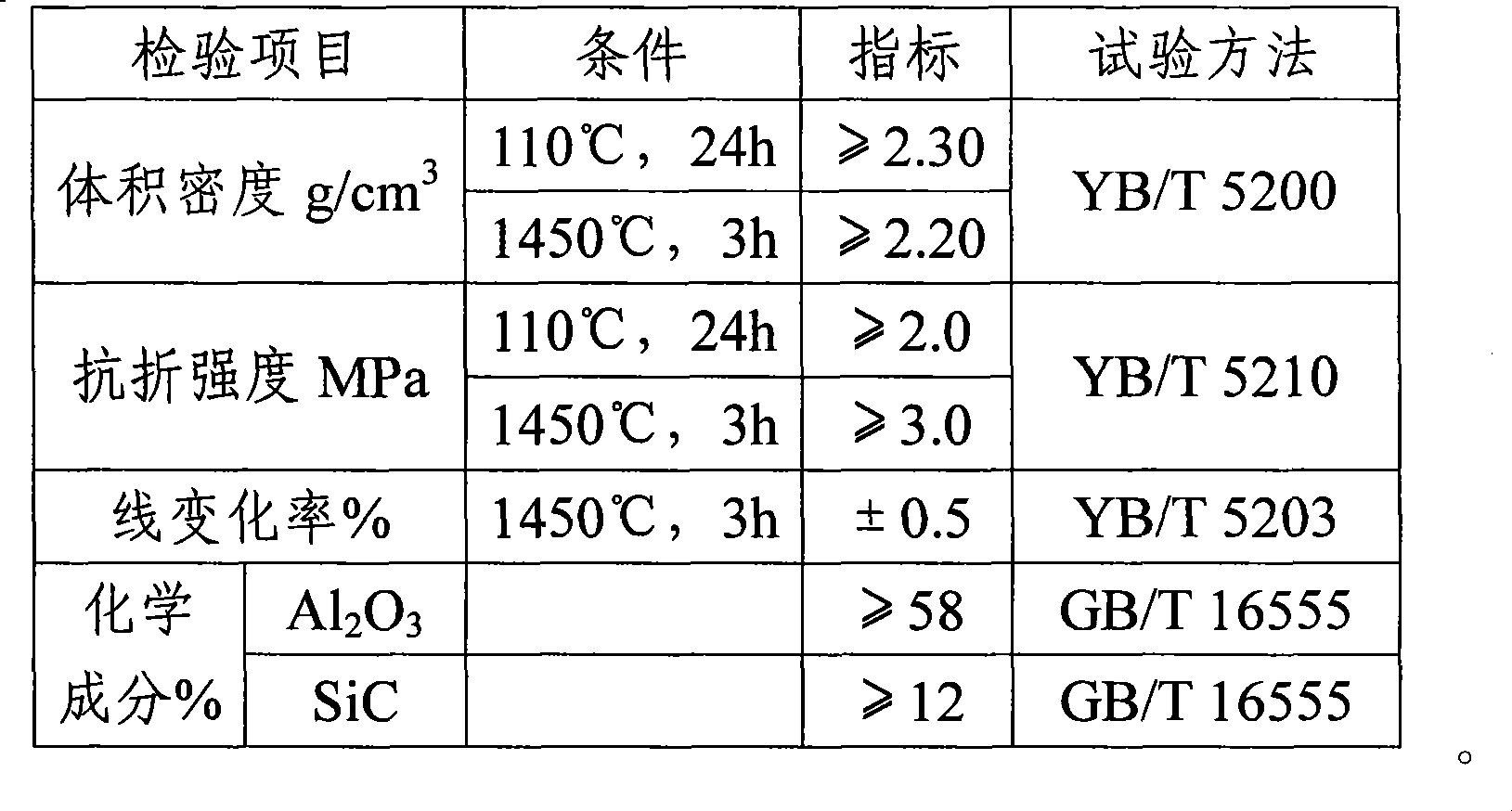

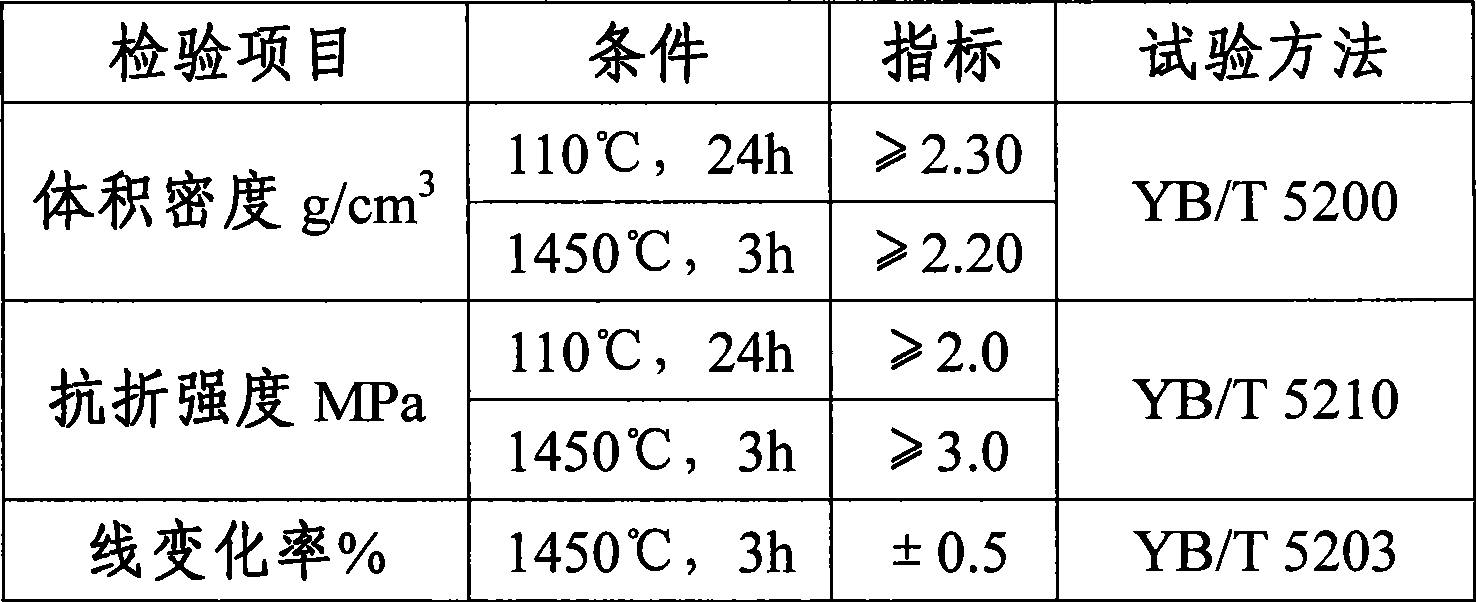

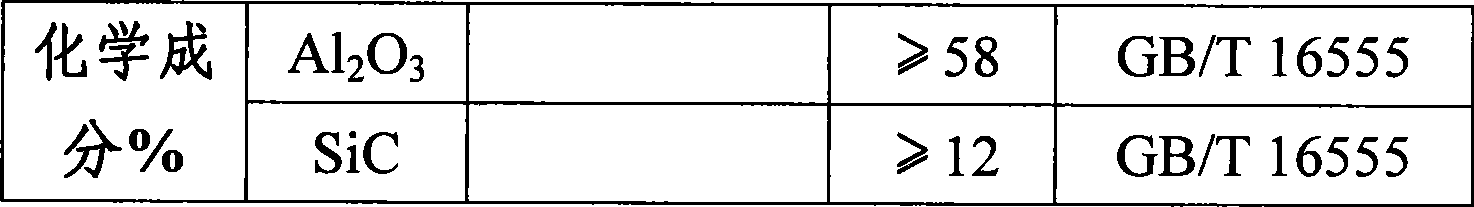

[0047] Raw material requirements:

[0048] The particle size of the finished material is less than or equal to 8mm, and the chemical composition is Al 2 o 3 +SiC≥70%, Fe 2 o 3 ≤2.0%.

[0049] The particle size of the finished material of recovered blast furnace dust collection powder is ≤0.044mm, and the chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com