Rolling bearing and method for manufacturing the same

A technology of rolling bearings and rolling elements, which is applied to bearing components, shafts, bearings, mechanical equipment, etc., can solve the problems of high cost and poor insulation, achieve high insulation performance, high corrosion resistance and chemical resistance, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

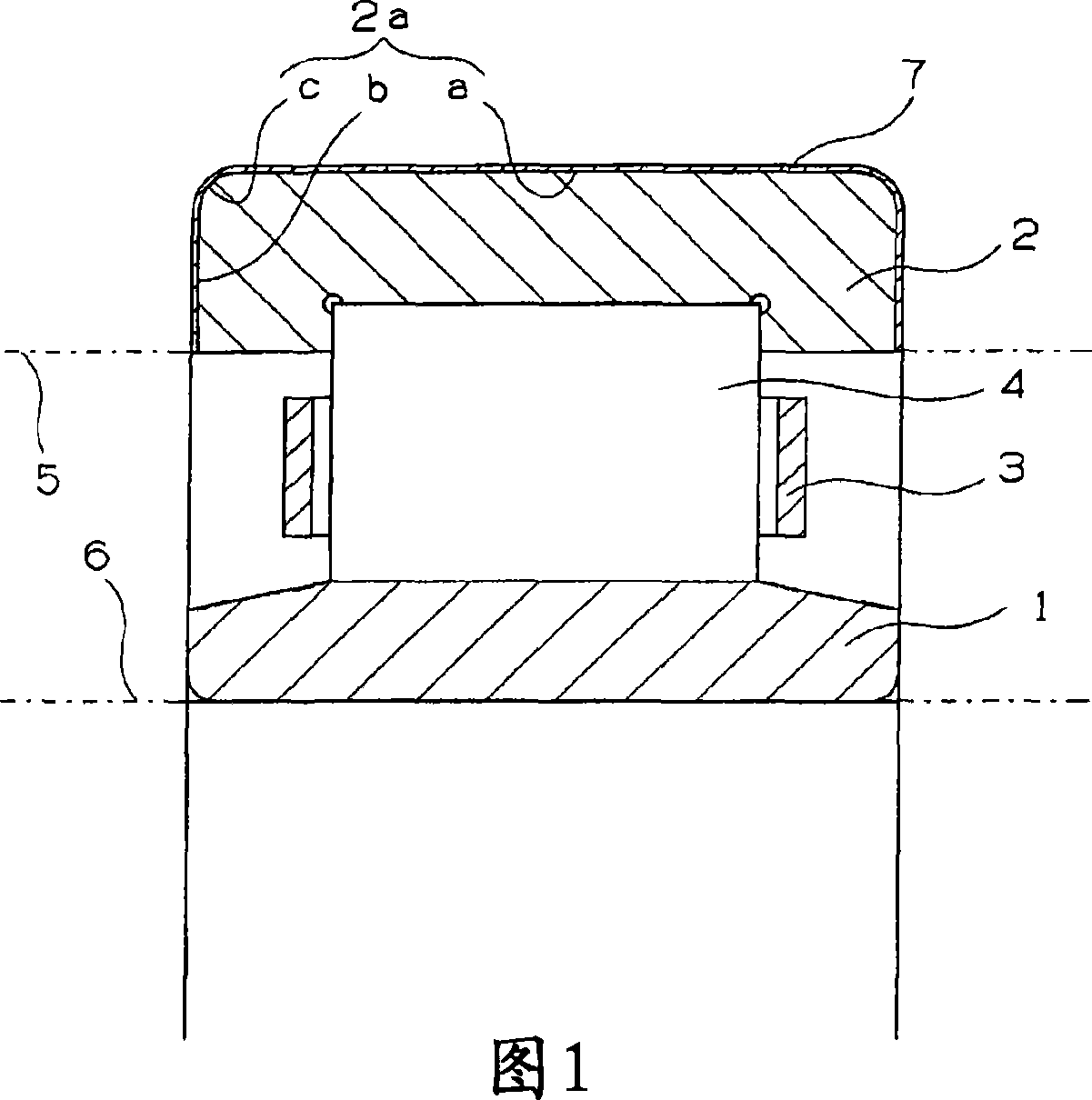

[0070] An insulated rolling bearing shown in FIG. 1 was produced as a test bearing (NU214, outer ring outer diameter: Φ125 mm, outer ring width: 24 mm). Here, on the outer peripheral surface 2a of the outer ring 2, the coating 7 made of alumina fine particles is formed by the AD method. The AD method uses a bearing drive unit that uses both an XY stage for positioning and a motor for rotating an object. The outer peripheral surface of the outer ring that rotates at a peripheral speed of 6mm / min while moving in the axial direction is under a reduced pressure of 100Pa or less. , by spraying an aerosol of alumina particles through a nozzle with an opening size of 5 mm×0.3 mm to form a coating. The film formation was performed until the film thickness became 4 μm.

[0071] The alumina fine particles were Taimicron TM-DAR manufactured by Taimyung Chemical Industry Co., Ltd., with an average particle diameter of 0.16 μm, and were used by heating and drying under a reduced pressure ...

Embodiment 2

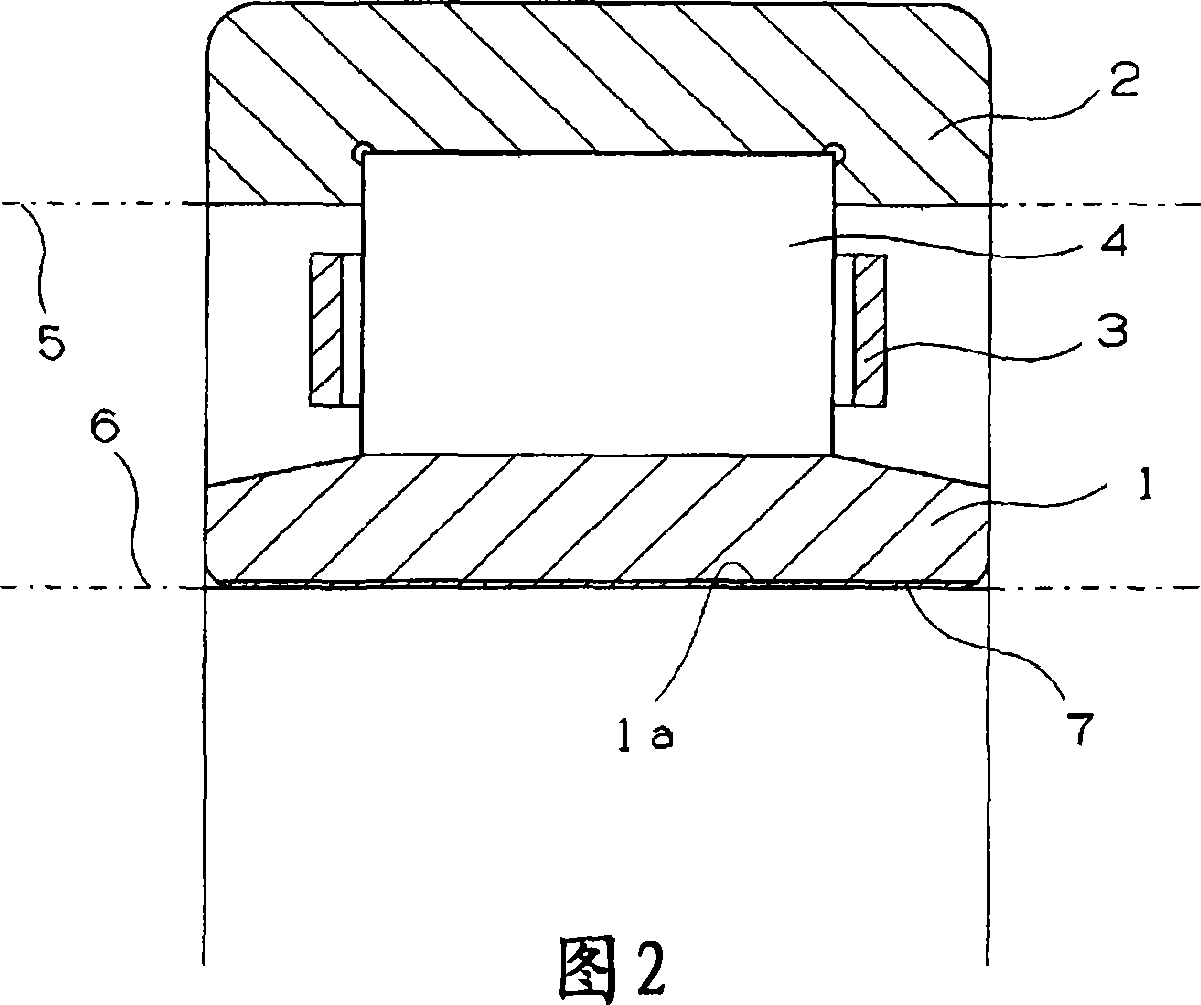

[0074]An insulated rolling bearing shown in FIG. 2 was fabricated as a test bearing. Here, the coating 7 made of alumina fine particles is formed on the inner peripheral surface 1a of the inner ring 1 by the AD method. The AD method uses a bearing drive unit that uses both an XY stage for positioning and a motor for rotating an object, and depressurizes at 100 Pa or less on the inner peripheral surface of the inner ring that rotates at a peripheral speed of 6 mm / min while moving in the axial direction. Next, an aerosol of alumina fine particles was sprayed through a nozzle with an opening size of 5 mm×0.3 mm to form a coating. The film formation was performed until the film thickness became 4 μm.

[0075] Alumina fine particles used the same product as in Example 1. It was confirmed that the obtained test bearings obtained a predetermined insulation resistance (at least 10MΩ / 500V load) between the inner peripheral surface of the outer ring and the outer peripheral surface of...

Embodiment 3

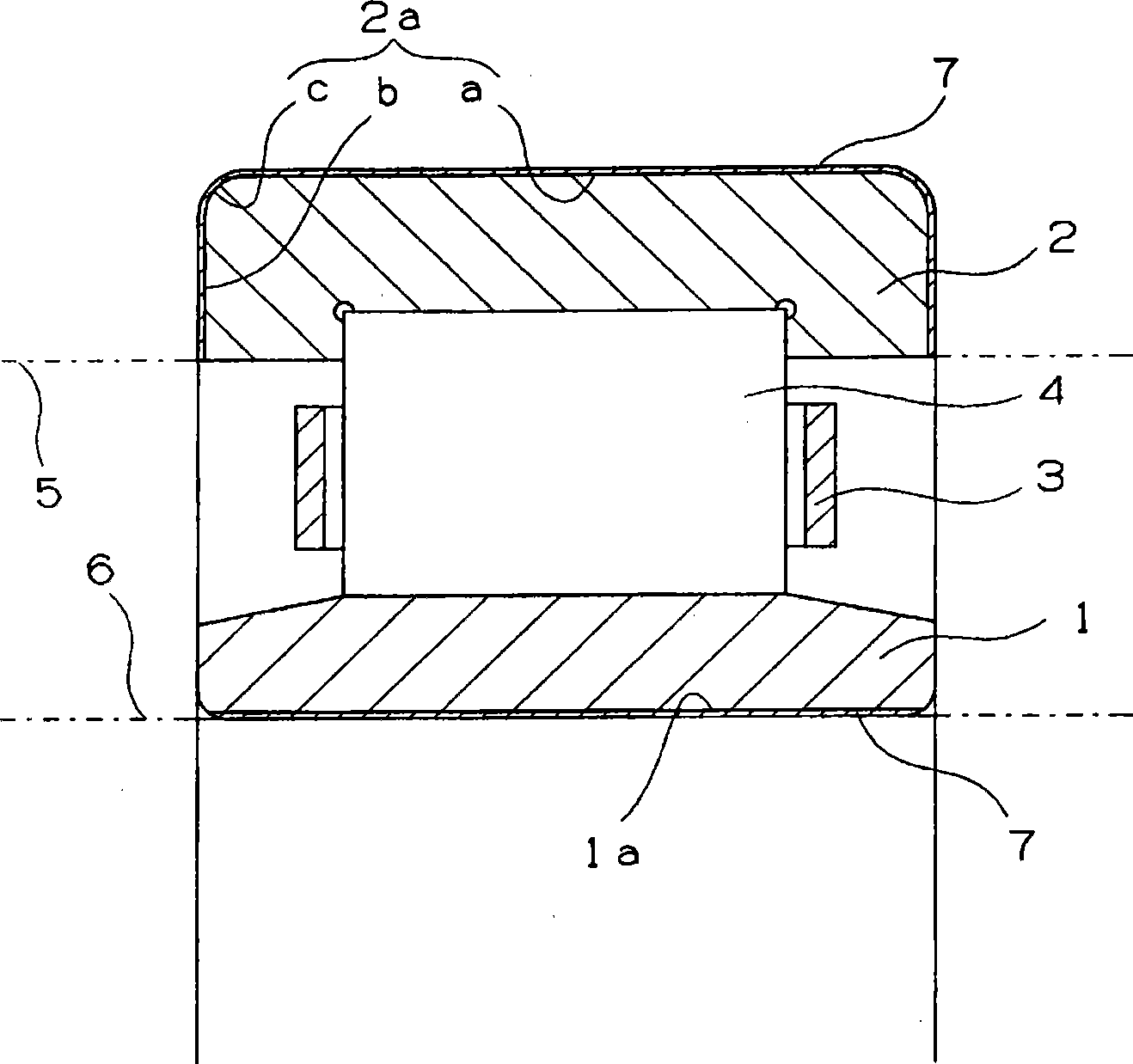

[0077] make image 3 The shown insulated rolling bearings were used as test bearings. Here, the coating 7 made of alumina fine particles is formed on the outer peripheral surface 2 a of the outer ring 2 and the inner peripheral surface 1 a of the inner ring 1 by the AD method. The AD method uses a bearing drive unit that uses both an XY stage for positioning and a motor for rotating an object. The outer peripheral surface of the outer ring that rotates at a peripheral speed of 6mm / min while moving in the axial direction is under a reduced pressure of 100Pa or less. , by spraying an aerosol of alumina particles through a nozzle with an opening size of 5 mm×0.3 mm to form a coating. The film formation was performed until the film thickness became 4 μm. Similarly, the coating is also formed on the inner peripheral surface of the inner ring.

[0078] Alumina fine particles used the same product as in Example 1. It was confirmed that the obtained test bearings obtained a predete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com