Fixing/releasing auxiliary device for a wafer detection platform, the wafer detection platform and method therefor

A technology of auxiliary device and testing device, which is applied in the direction of measuring device casing, semiconductor/solid-state device testing/measurement, single semiconductor device testing, etc., and can solve the problem of inability of point measuring device to make correct conductive contact, lower output efficiency, and increase of carrying device Vacuum pump suction power and other issues, to improve detection efficiency and output yield, reduce wafer damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

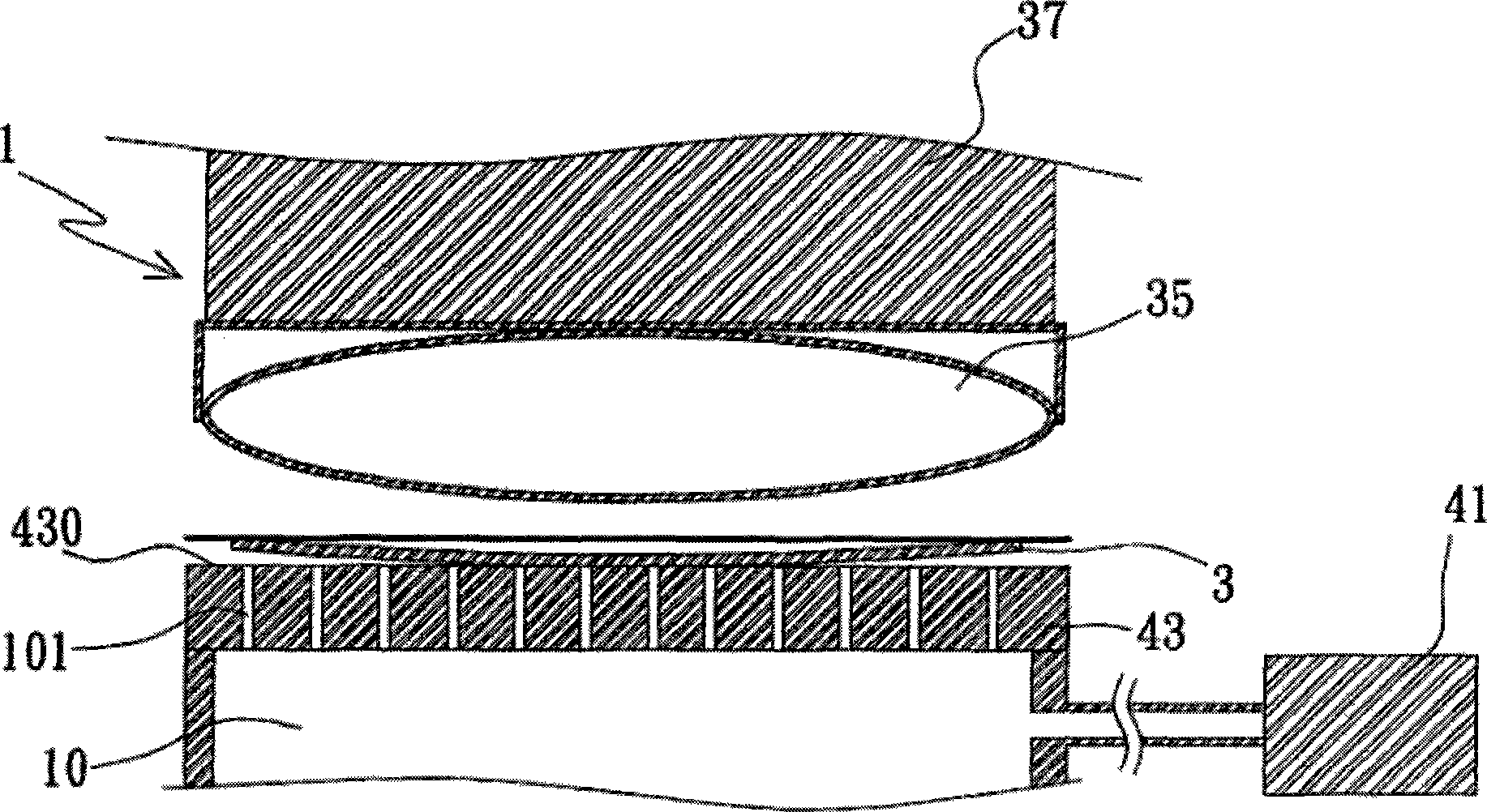

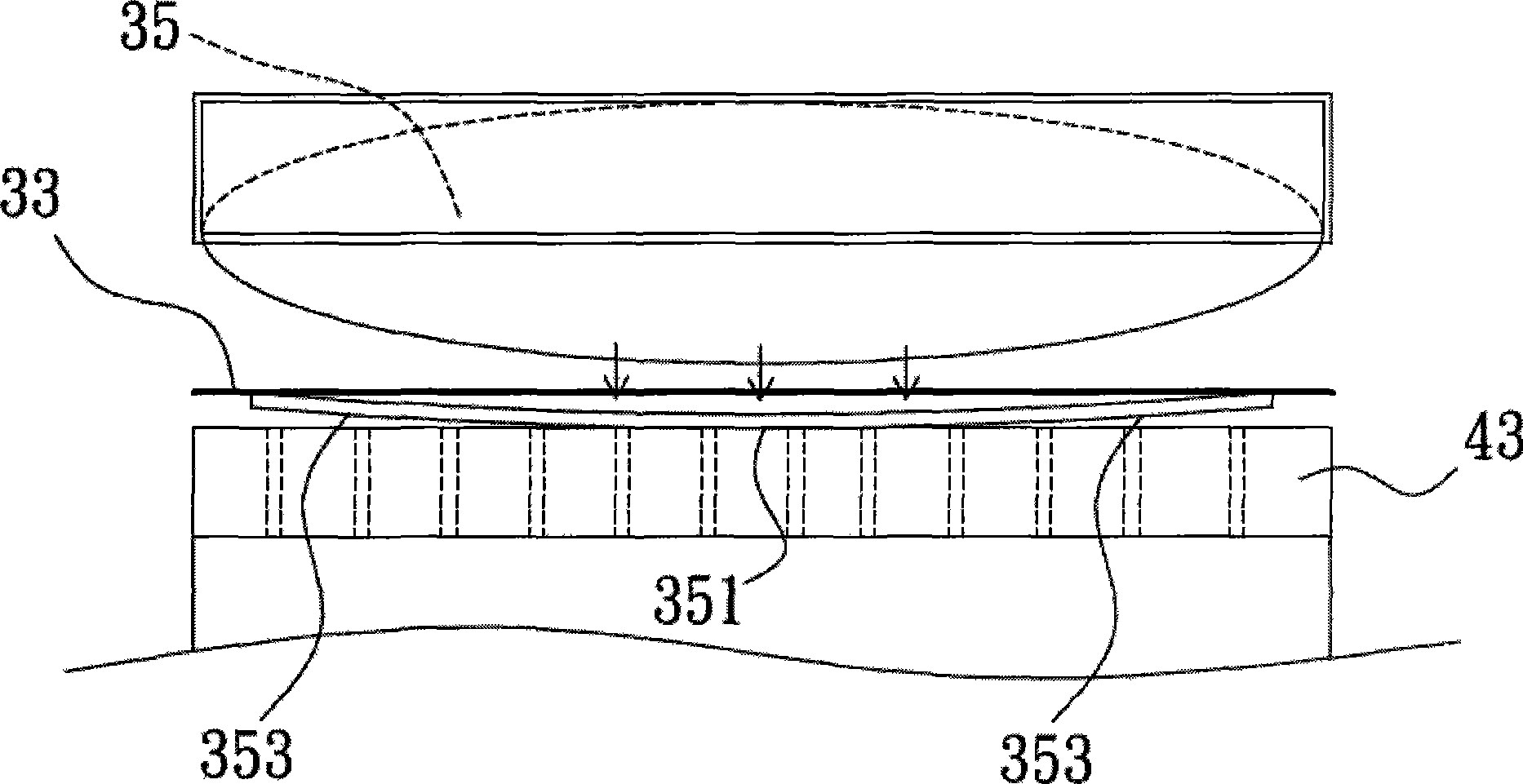

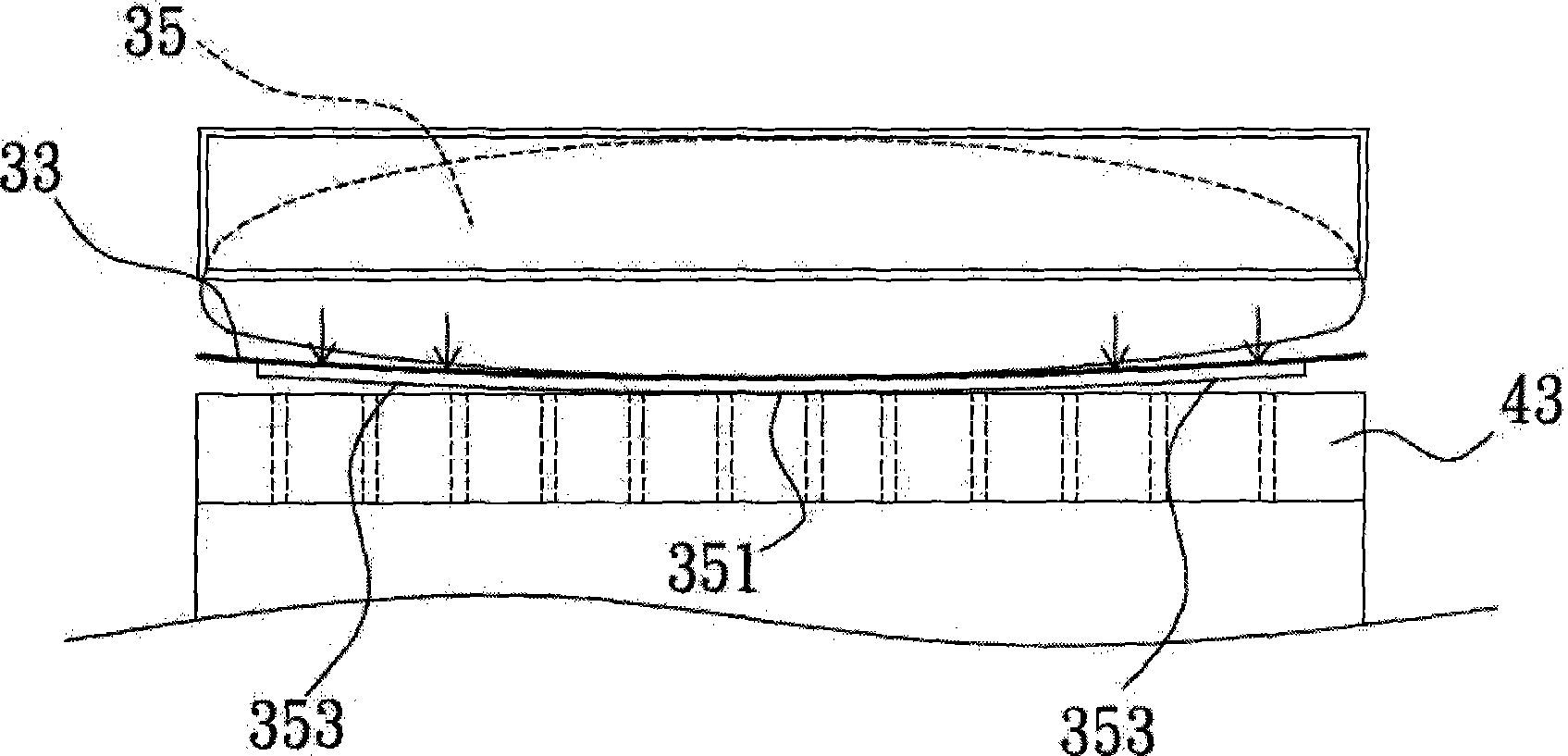

[0026] The present invention as figure 1 and figure 2 As shown, the fixing / releasing auxiliary device 1 utilizes a hollow sphere 35 whose central part 351 is obviously thicker than the peripheral part 353 as a flexible unit for applying pressure. reserve position, so Figure 6 In step 61 , after the wafer 3 to be tested is placed on the carrying surface 430 of the carrying device 43 , the ball 35 is moved to the top of the wafer 3 to be tested and gradually pressed down. Among them, the warpage of the wafer 3 to be tested is not radially symmetrical, but generally because the central part 351 is the lowest, it is close to a flat state when it is placed on the carrying surface 430; and at this time, the air holes 101 on the carrying surface 430 have been ventilated The connected exhaust pump 41 applies negative pressure.

[0027] Therefore step 62 as Figure 1 to Figure 5 As shown, the central part 351 of the sphere 35 will preferentially press against the center of the wa...

no. 2 example

[0033] Of course, as those skilled in the art can easily understand, the flexible unit is not limited to hollow spheres, such as Figure 7 As shown in the second embodiment of this case, solid flexible members such as sponge 35' can also be used to make the thickness of the peripheral part 353' less than that of the central part 351', and when the wafer is finally flattened, the central part The thickness of 351' can be substantially equal to that of the peripheral part 353', which can meet the needs of this case, and exert pressure on the wafer surface to perform inspection operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com