Anisotropic magnetic powder and manufacturing method thereof

An anisotropic, magnetic powder technology, applied in the field of rare earth-iron-boron alloy and anisotropic bonded magnetic powder manufacturing, can solve the problem of difficult to obtain high-performance bonded magnets, difficult to reduce the content of rare earth alloys, rich neodymium Problems such as uneven phase distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

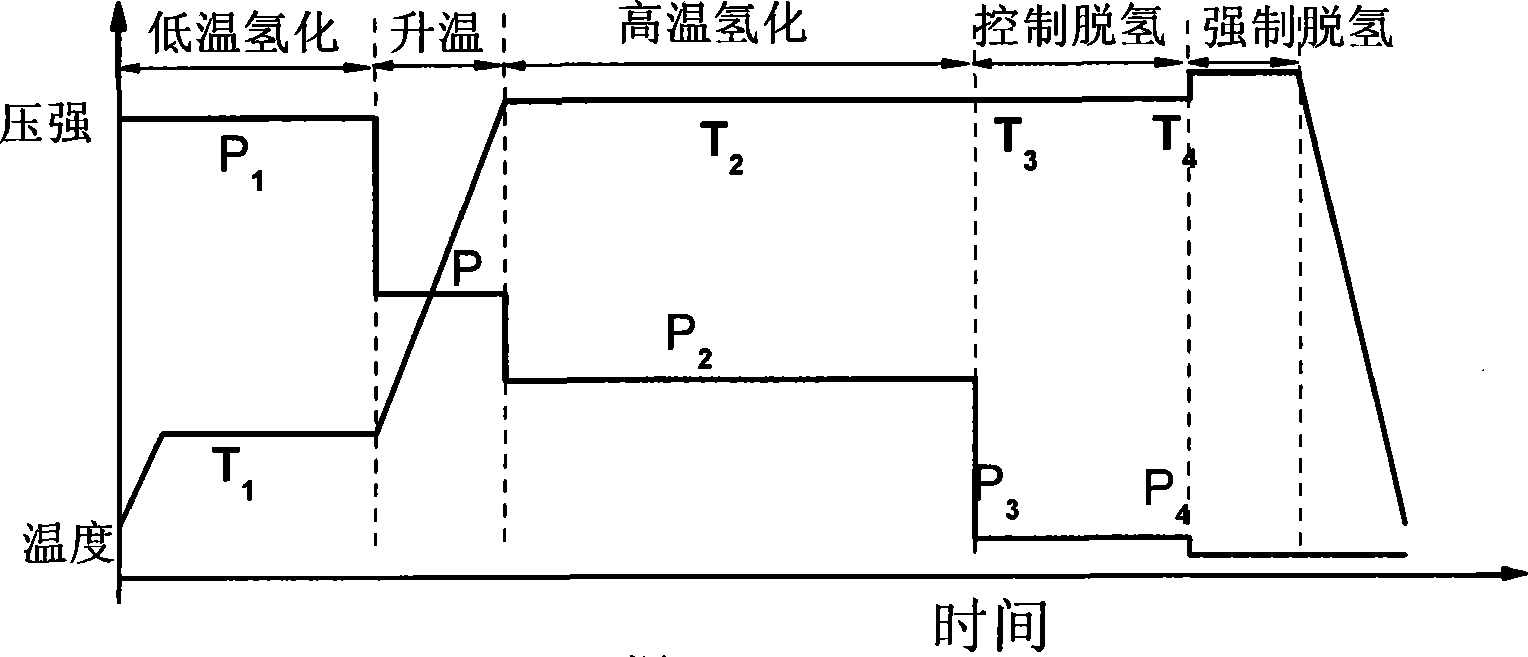

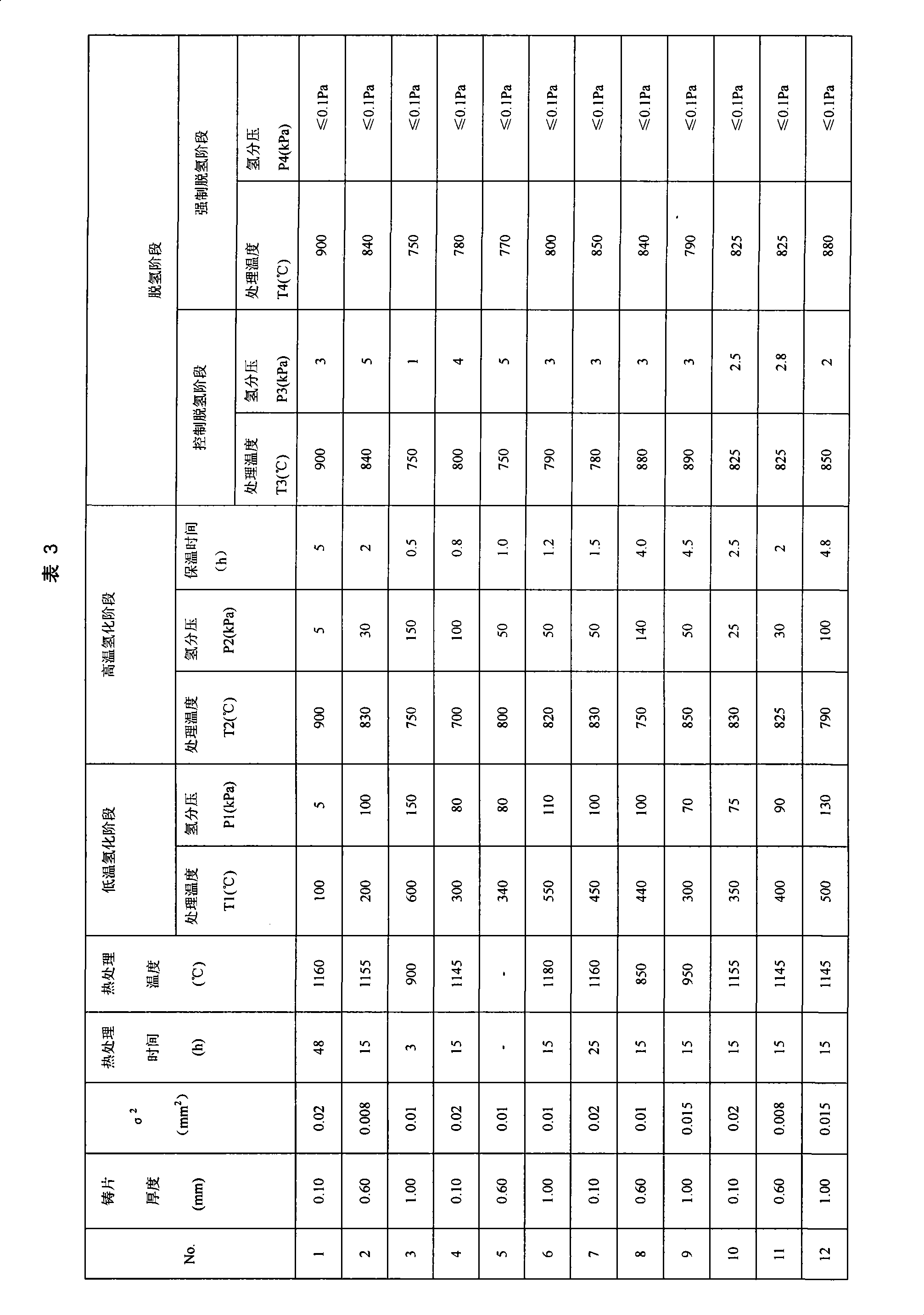

[0026] According to the ingredient distribution shown in Table 1. Its preparation method is: under the protection of inert gas, use medium frequency induction melting to form rare earth alloy melt, and then cast it on the rotating water-cooled copper roller in the form of plane flow through the casting tank, and obtain the alloy casting at the speed of water-cooled roller shown in Table 3. Sheet, cast sheet thickness and σ 2 See Table 3, the obtained alloy cast pieces were heat-treated (or not) in vacuum or inert gas atmosphere according to the temperature and time shown in Table 3. The heat-treated (or untreated) alloy cast pieces are put into a hydrogenation device for hydrodehydrogenation treatment under the process conditions shown in Table 3, and the properties of the obtained magnetic powder are shown in Table 2.

[0027] Table 1

[0028] Element Nd Pr Fe B Ga Al Zr Nb Proportion (atm%) 12.5 0.3 margin 6.4 0.3 0.1 0.2 0.1

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com