Suspending magnetization roasting furnace

A magnetized roasting and furnace body technology, applied in fluidized bed furnaces, furnaces, furnace types, etc., can solve the problems of long lag time in temperature adjustment, low iron ore reduction rate, easy to produce over-burning and under-burning, etc. Environmental protection and social benefits, high magnetic susceptibility, and easy large-scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

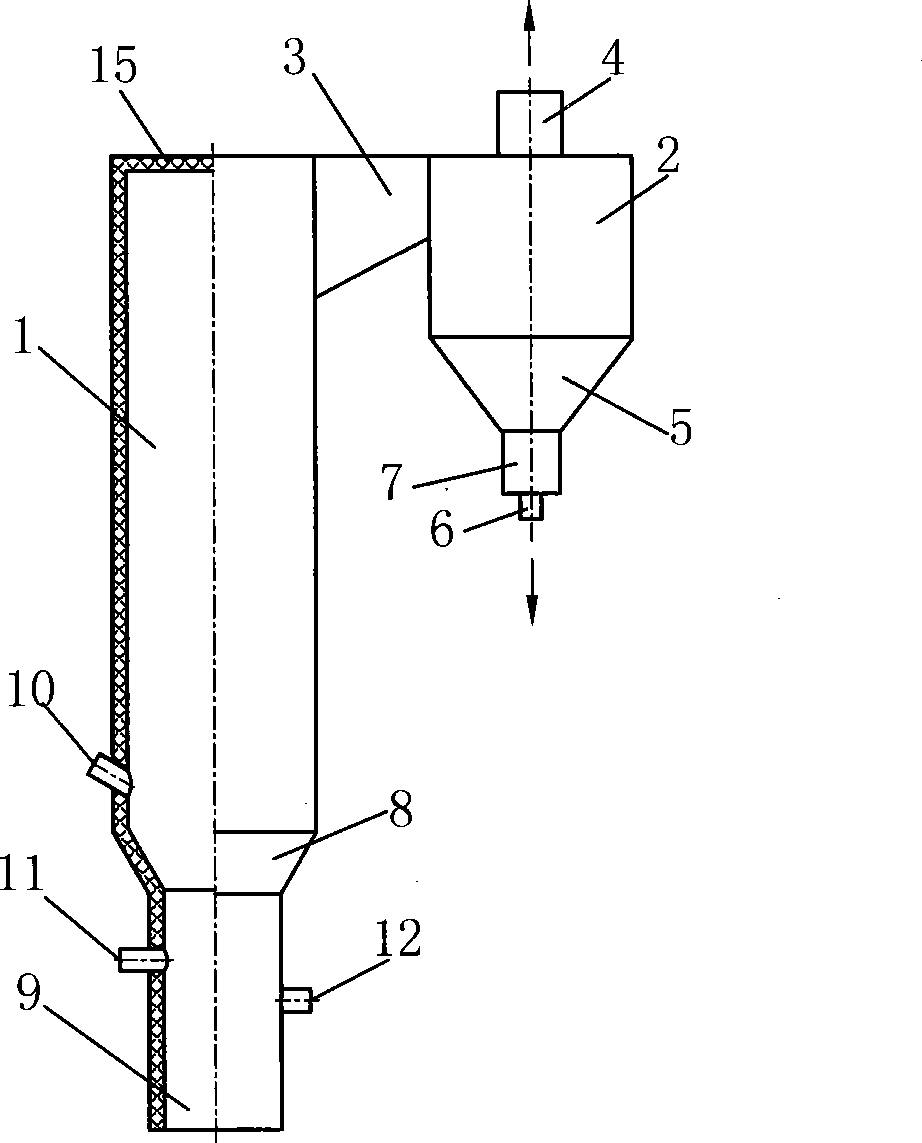

Embodiment 1

[0021] The suspension magnetization roasting furnace is composed of a furnace body 1 and a cyclone separator 2 of the suspension magnetization roasting furnace with a refractory lining. The top cover of the cyclone separator is fixedly connected with an exhaust pipe 4, and the lower end of the cone body 5 of the cyclone separator 2 is fixedly connected with a discharge pipe 6, and the discharge pipe 6 is equipped with a capacity expansion type voltage stabilizer 7. The furnace roof 15 of the body of furnace 1 is a flat furnace roof, and the upper part of the body of furnace of the suspension magnetization roasting furnace is a cylinder, and the lower part of the cylinder is a frustum body 8 and a vertical conduit 9, which are fixedly connected to form an integral body. A feed inlet 10 is fixed on the lower wall of the furnace body 1 , and a heat supply inlet 11 of an auxiliary burner and a heat supply inlet 12 of a heat supply roaster are installed on a vertical conduit 9 .

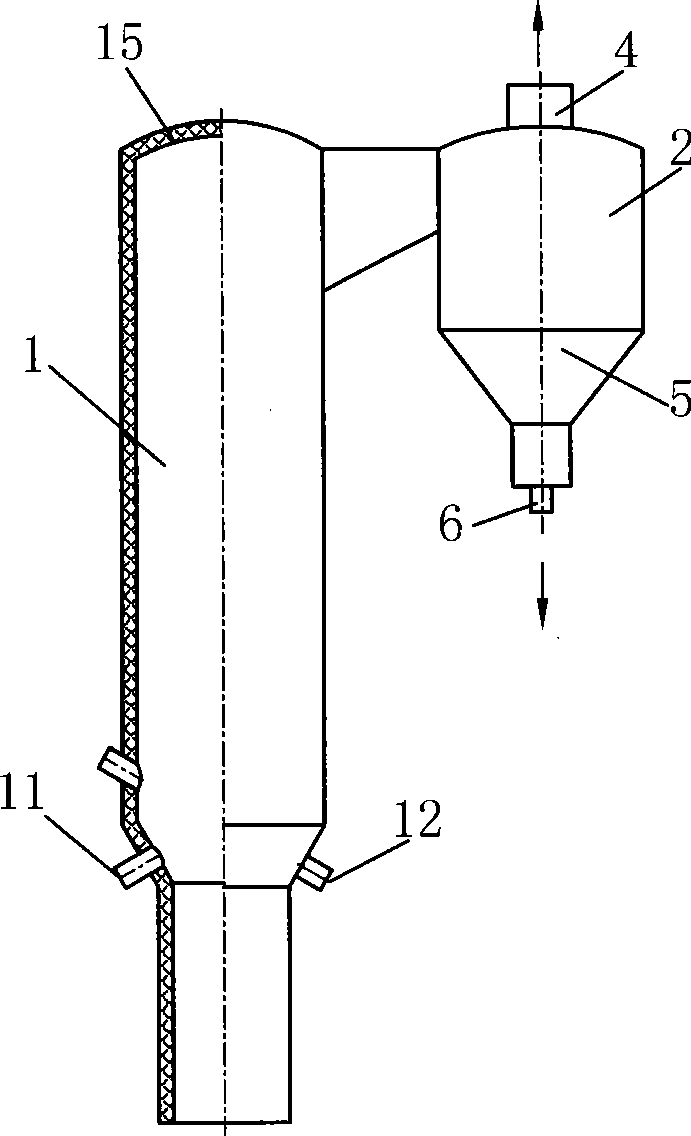

Embodiment 2

[0023] Embodiment 2 is basically the same as Embodiment 1 in structure, and the difference is that the furnace roof 15 of the furnace body 1 of the suspension magnetization roasting furnace is an arched furnace roof, and the heating inlets 11 and 12 are respectively fixed on the frustum body 8 .

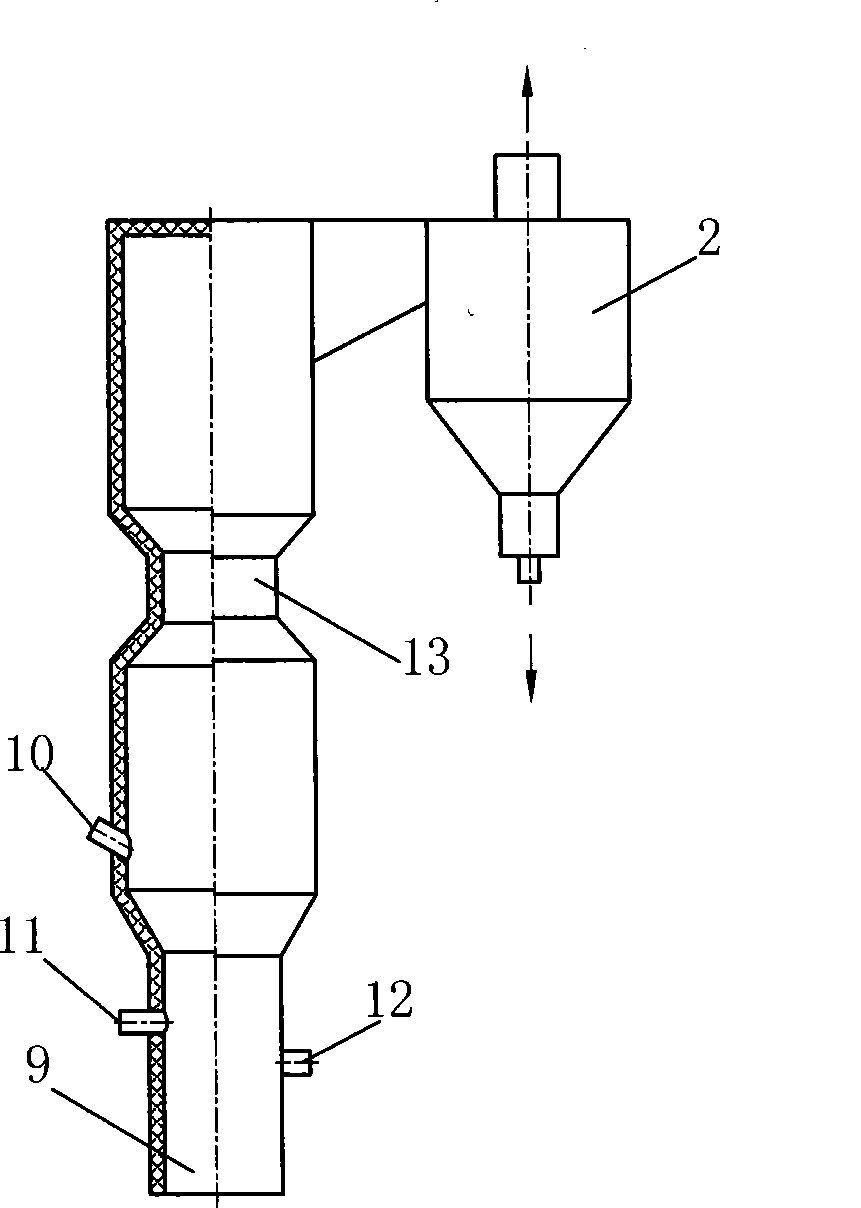

Embodiment 3

[0025] The structure of the third embodiment is basically the same as that of the first embodiment, except that the middle part of the furnace body 1 of the suspension magnetization roasting furnace is a concave saddle-shaped pipe body 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com