White mineral oil for polystyrol

A polystyrene and white mineral oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems such as the thermal stability and light stability of crystalline polystyrene oil that cannot be fully achieved. Achieve the effect of improved impact strength, suitable hydrocarbon composition and deep refining degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

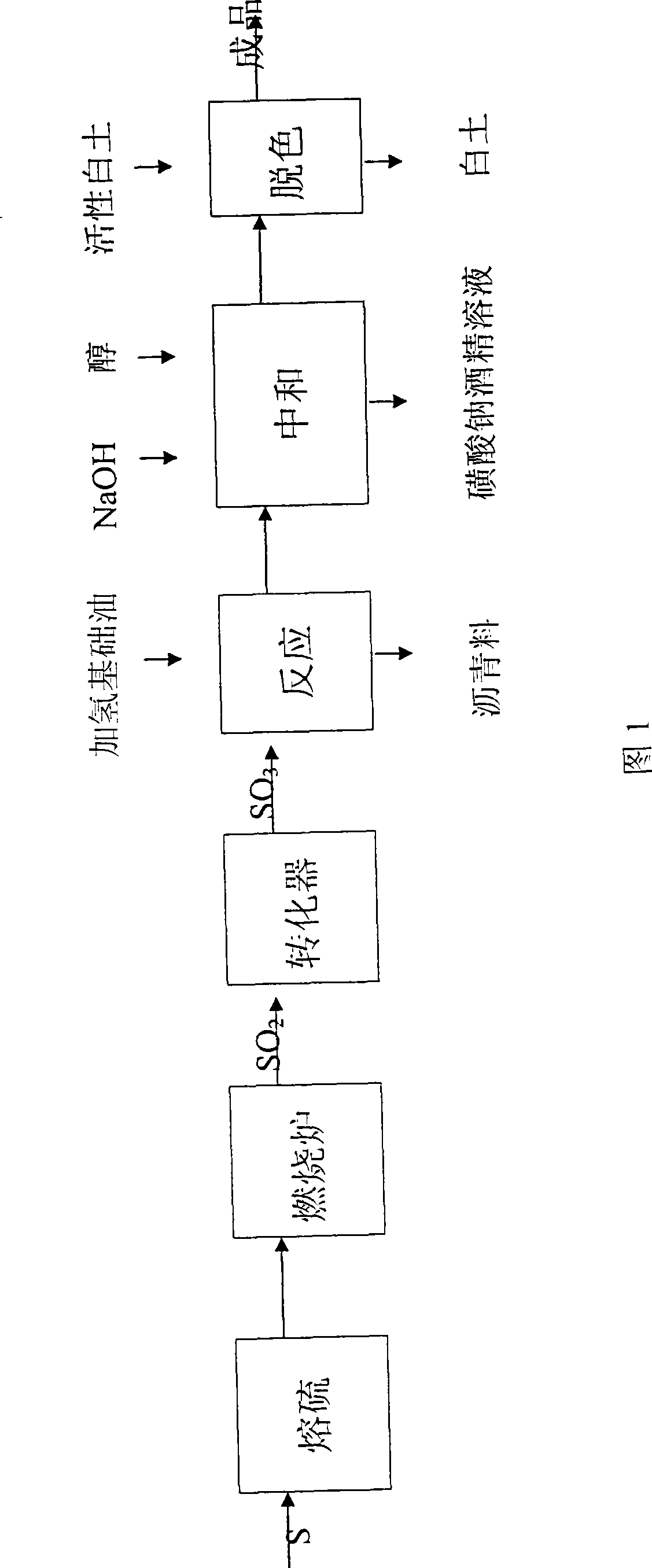

Method used

Image

Examples

Embodiment 1

[0026] Three-stage hydrogenated base oil A (Xinjiang naphthenic oil K371) obtained by three-stage hydrogenation of fractions at 350-550°C in the subtraction line 4 after atmospheric fractionation of Xinjiang Karamay Oilfield crude oil;

[0027] After normal-pressure fractionation of crude oil in Daqing Oilfield, take the 350-550°C cut section of the minus four line and adopt conventional isomerization hydrogenation to obtain isomerization hydrogenation base oil B;

[0028] After normal pressure fractionation of crude oil in Daqing Oilfield, take the 330-500°C fraction of the third minus line and adopt conventional isomerization hydrogenation to obtain isomerization hydrogenation base oil C;

[0029] Take three-stage hydrogenated base oil A35%+isomerized hydrogenated base oil B35%+isomerized hydrogenated base oil C30% to form a mixed base oil, and use sulfur trioxide gas phase sulfonation method to sulfonate the base oil, wherein, Gas-phase sulfonation at 55°C for 18 hours, the...

Embodiment 2

[0034] Three-stage hydrogenated base oil A (Xinjiang naphthenic oil KNH4010) obtained from the three-stage hydrogenation of the 350-550°C fraction section of the fourth reduction line after atmospheric fractionation of crude oil in Karamay Oilfield, Xinjiang;

[0035] After normal-pressure fractionation of crude oil in Daqing Oilfield, take the 350-550°C cut section of the minus four line and adopt conventional isomerization hydrogenation to obtain isomerization hydrogenation base oil B;

[0036] After normal pressure fractionation of crude oil in Daqing Oilfield, take the 330-500°C fraction of the third minus line and adopt conventional isomerization hydrogenation to obtain isomerization hydrogenation base oil C;

[0037] Take the three-stage hydrogenated base oil A30%+isomerized hydrogenated base oil B30%+isomerized hydrogenated base oil C40% to form a mixed base oil, and use the sulfur trioxide gas phase sulfonation method to sulfonate the base oil, wherein, Gas-phase sulfo...

Embodiment 3

[0042] Three-stage hydrogenated base oil A (Xinjiang naphthenic oil KP6010) obtained from the three-stage hydrogenation of the 350-550°C fraction section of the fourth reduction line after atmospheric fractionation of crude oil in Karamay Oilfield, Xinjiang;

[0043] After normal-pressure fractionation of crude oil in Daqing Oilfield, take the 350-550°C cut section of the minus four line and adopt conventional isomerization hydrogenation to obtain isomerization hydrogenation base oil B;

[0044] After normal pressure fractionation of crude oil in Daqing Oilfield, take the 330-500°C fraction of the third minus line and adopt conventional isomerization hydrogenation to obtain isomerization hydrogenation base oil C;

[0045] Take the three-stage hydrogenated base oil A40%+isomerized hydrogenated base oil B40%+isomerized hydrogenated base oil C20% to form a mixed base oil, and use the sulfur trioxide gas phase sulfonation method to sulfonate the base oil, wherein, Gas-phase sulfonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com