Method for preparing developing polyurethane

A polyurethane and developable technology, applied in catheters, medical science, prostheses, etc., can solve problems such as loss of developable atoms and product changes, and achieve good physical properties, easy processing, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

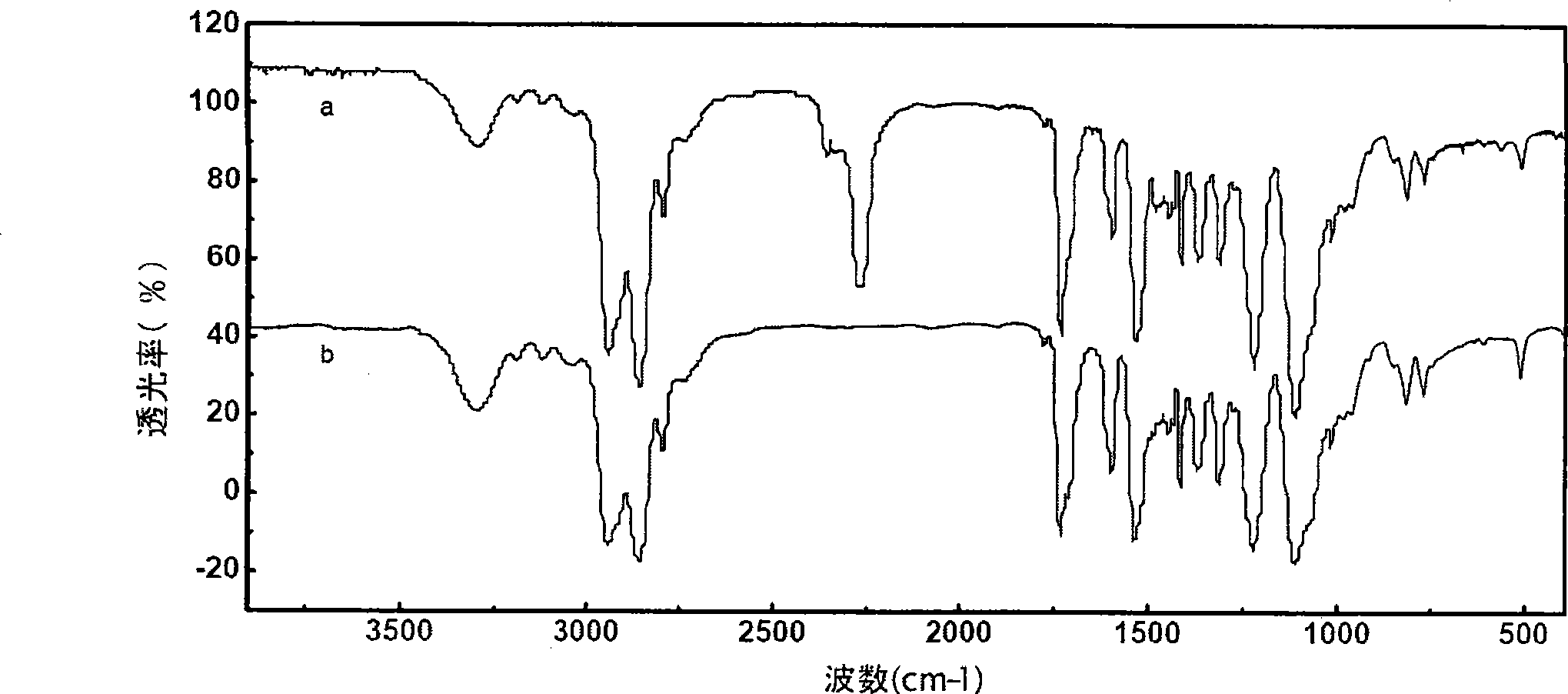

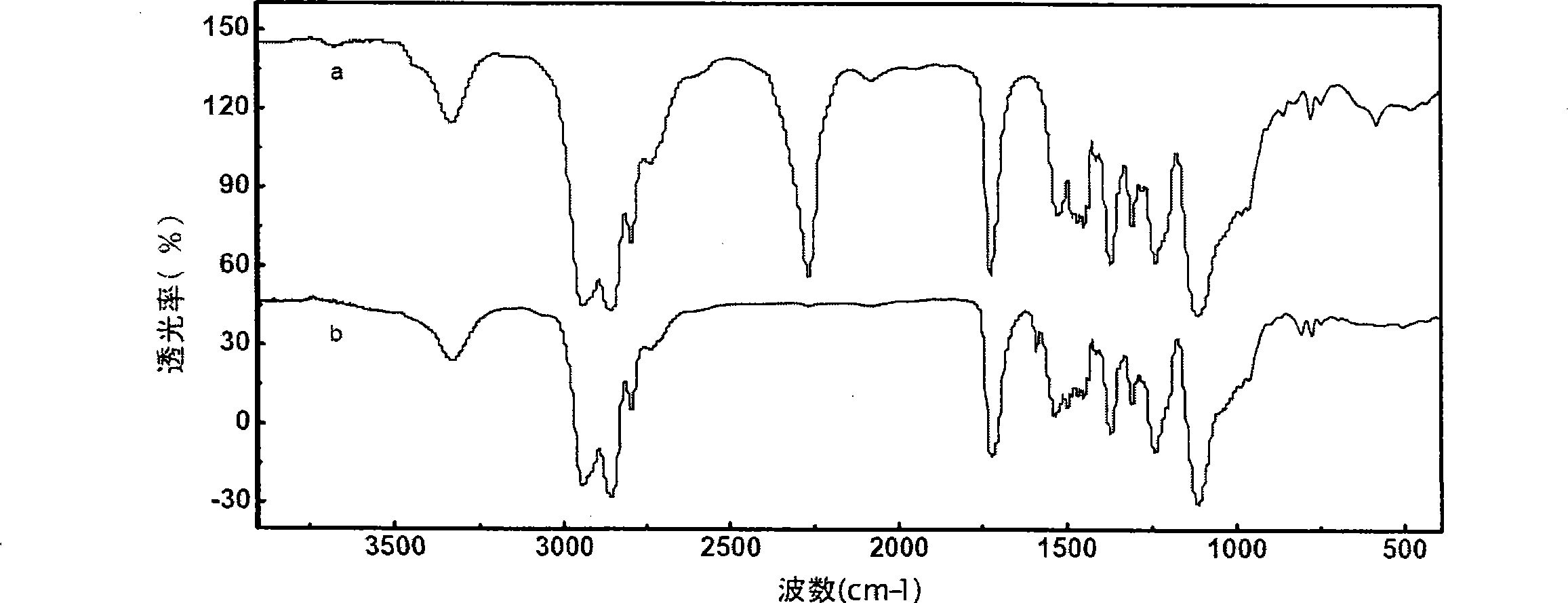

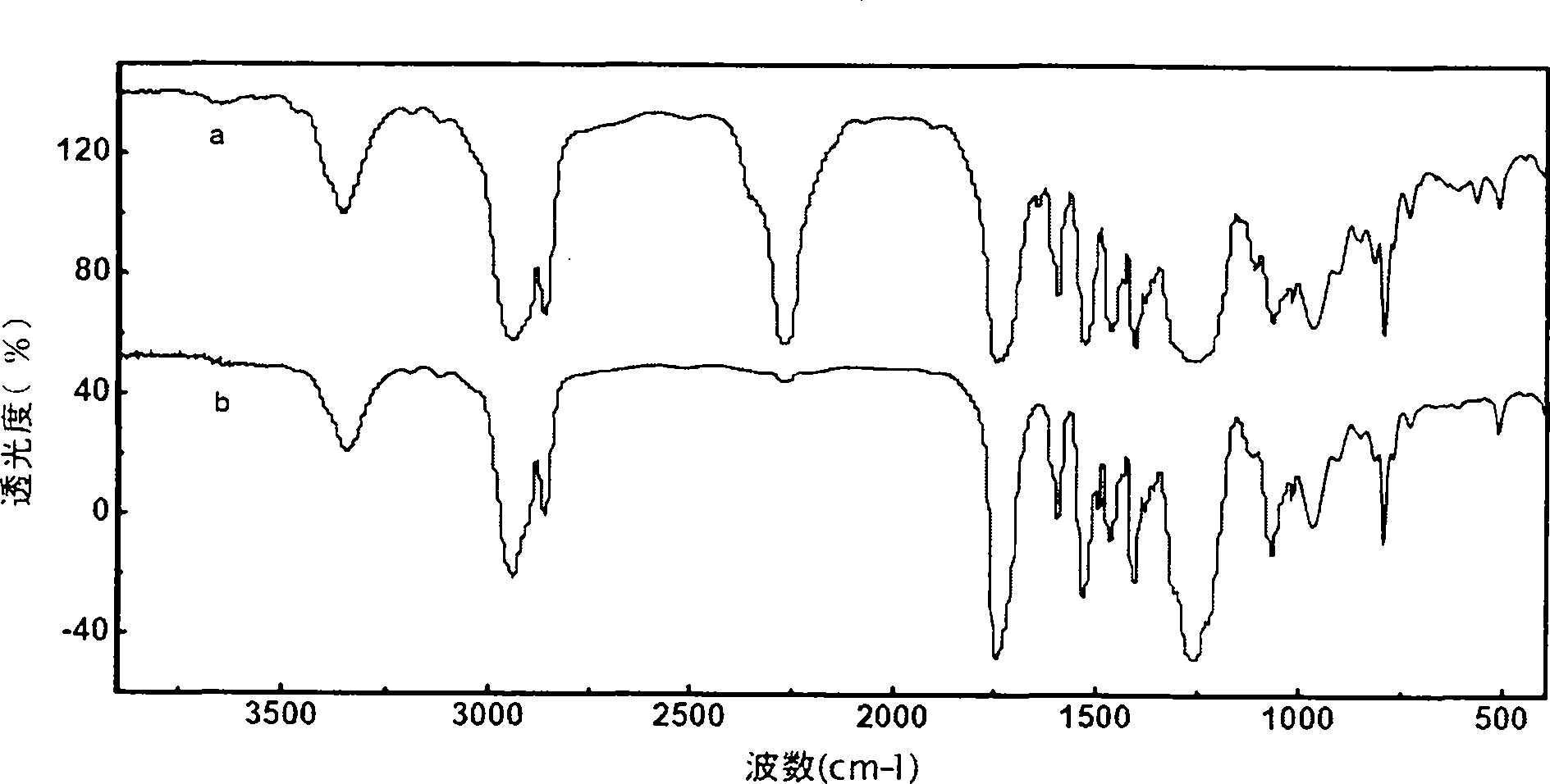

Embodiment 1

[0032] Example 2:

[0033] Mix the pre-vacuum dehydrated polytetrahydrofuran ether diol with a molecular weight of 2000 and isophorone diisocyanate in a molar ratio of 0.46:1, stir and mix at 78°C for 5 hours under the protection of nitrogen to obtain a prepolymer; When the temperature reaches 85°C, add the pre-melted chain extender N, N-dihydroxyethyl-p-iodoaniline, the molar ratio of which to isophorone diisocyanate is 0.49:1, stir for about 3 hours, and add 0.08% of the total mass % catalyst stannous octoate, and then stirred for 10 minutes, discharged, and the obtained polymer was matured at a temperature of 75° C. for 4 hours.

Embodiment 2

[0035] Example 3:

[0036] Mix the poly(1,6-hexanediol) diol with a molecular weight of 2000 and 4,4'-diphenylmethane diisocyanate with a molecular weight of 2000 before vacuum dehydration, and the molar ratio of mixing is 0.49:1. Stir and mix at 80°C for 2.5 hours to obtain a prepolymer; raise the temperature to 90°C, add the pre-melted chain extender N,N-dihydroxyethyl-p-iodoaniline, which is mixed with 4,4'-diphenylmethane The molar ratio of diisocyanate is 0.50:1, the reaction is stirred for about 10 minutes and the material is discharged, and the obtained polymer is aged at a temperature of 75°C for 3 hours.

Embodiment 3

[0038] Figure 4 It is the development effect diagram of the developable polyurethane prepared in the above-mentioned Examples 1, 2 and 3.

[0039] Wherein, A) standard aluminum plate, B) non-developing polyurethane (polycarbonate polyurethane with 1,4-butanediol as chain extender), C) sample prepared in Example 1, D) prepared in Example 2 Sample, E) The sample prepared in Example 3.

[0040] The developable polyurethane prepared in the example was dissolved in THF, and the solvent was volatilized in a glass petri dish to form a film with a film thickness of 2 mm. Using a standard clinical X-ray instrument (GE, XR / A) through a 2.5mm aluminum filter to test under the condition of 60kV×10mA×0.2s, the sample film has the minimum radiopacity required in the polymer resin developability test The resistance is equivalent to the aluminum plate (ISO4049-1978) with a thickness of 2mm. It can be seen from the figure that compared with the non-developable polyurethane, the developable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com