Chinese almond cake and production method thereof

An almond biscuit and a production process technology, applied in food preparation, baking, baked food and other directions, can solve the problems of single nutrient composition of macaroons, difficulty in forming process technology, unscientific ratio, etc. Good, scientific and reasonable effect of nutritional ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

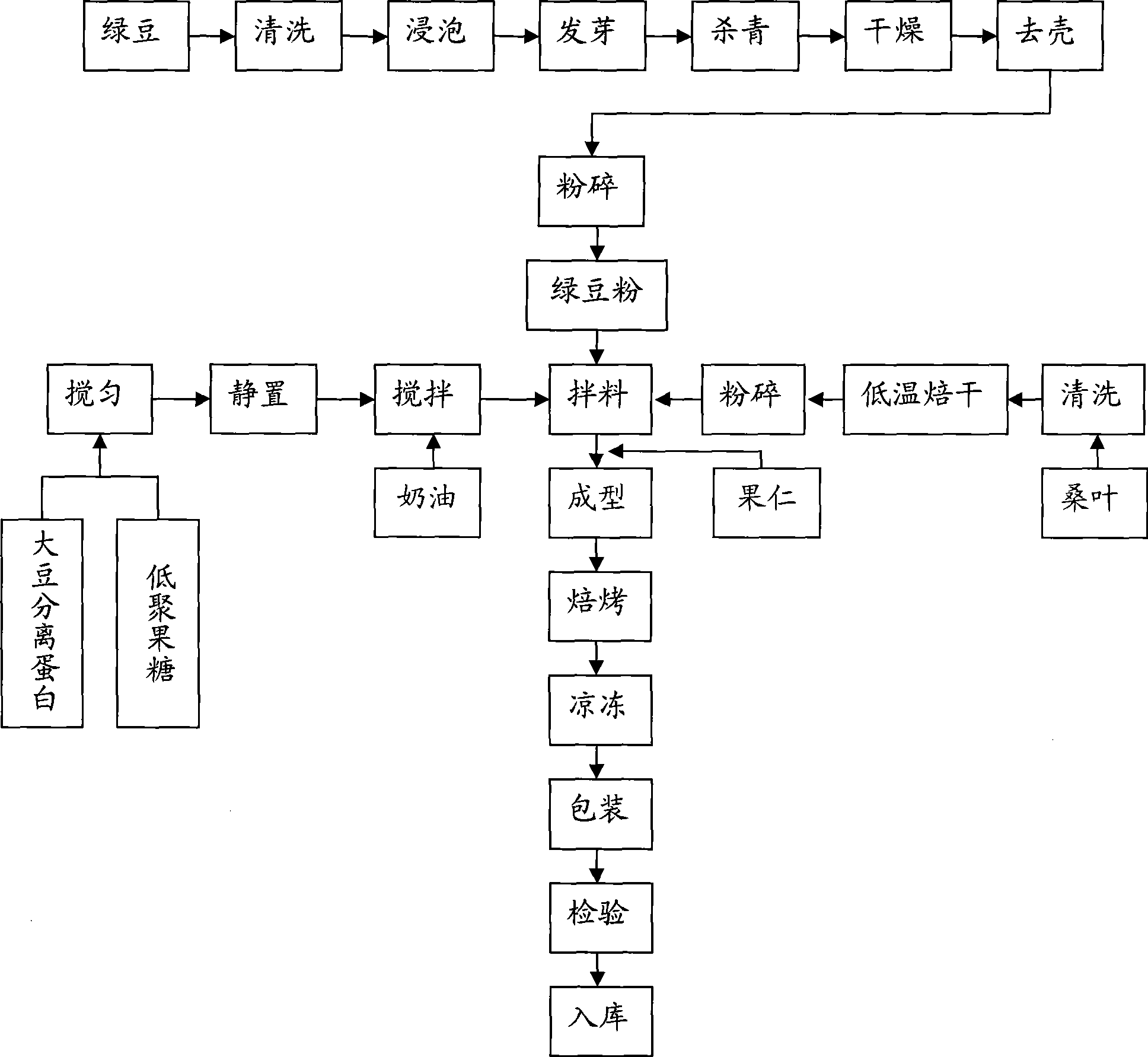

Method used

Image

Examples

Embodiment 1

[0024] Select 150 kg of first-grade mung beans, use cleaning and impurity removal equipment to remove sediment, impurities, and microorganisms adhering to the mung bean skin; send the cleaned and removed mung beans into the soaked bean germination basket, and place them in a heat preservation tank. The weight ratio of beans to water is 1:3~1:2.5, the temperature is 60~80°C, and the time is 3~5 minutes; heat treatment soaks the heat-treated mung beans, the weight ratio of beans to water is 1:3~1:2.5, and the water temperature is 37 ~40°C, time 4-5 hours; remove soaked bean water, transfer soaked mung beans to another heat preservation tank for heat preservation and germination, room temperature controlled at 37-40°C, humidity above 85%, germination time 4-5 hours , the average bud length at the end is 5-10 mm; use the greening furnace for high-temperature instantaneous killing, the furnace wall temperature is 600-700 °C, the beans stay in the furnace for 8-12 seconds, and the te...

Embodiment 2

[0026] Mulberry leaf preparation: When picking mulberry leaves, it is necessary to prevent leaf veins from being injured, because the overflowing juice will oxidize and change color when exposed to air, and pick out mulberry leaves with black spots, brown spots, and pests. Take fresh mulberry leaves, place them in a drying box, bake them at 45-55°C for 12-18 hours, and dry them with hot air until the water content of the mulberry leaves drops below 5-10%. The mulberry leaves were crushed into 200-mesh powder with a supersonic colliding jet mill, and the powder was collected.

Embodiment 3

[0028] Select first-grade mung beans, wash, soak, germinate, kill, dry, peel and finely grind mung bean powder. The preparation method of the mulberry leaf powder comprises the steps of cleaning, washing, low-temperature drying, crushing, etc., to obtain the dry mulberry leaf powder for future use. Add 100 grams of soybean protein isolate and 250 grams of fructo-oligosaccharide into the mixing tank and stir to emulsify evenly. In order to ensure the sufficient water absorption of soybean protein isolate, add fructo-oligosaccharide syrup and stir to mix. After standing for 45 minutes, add 50 grams of cream and stir well. Then add 400 grams of prepared mung bean powder and 30 grams of mulberry leaf powder and mix well to form a powder, then put the prepared powder in a cake mold to form a cake, put it into the oven for baking, the temperature is 75 ° C, and the time is 50 minutes, cooling, sorting, packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com