Method for preparing leadless piezoelectric potassium sodium niobate film

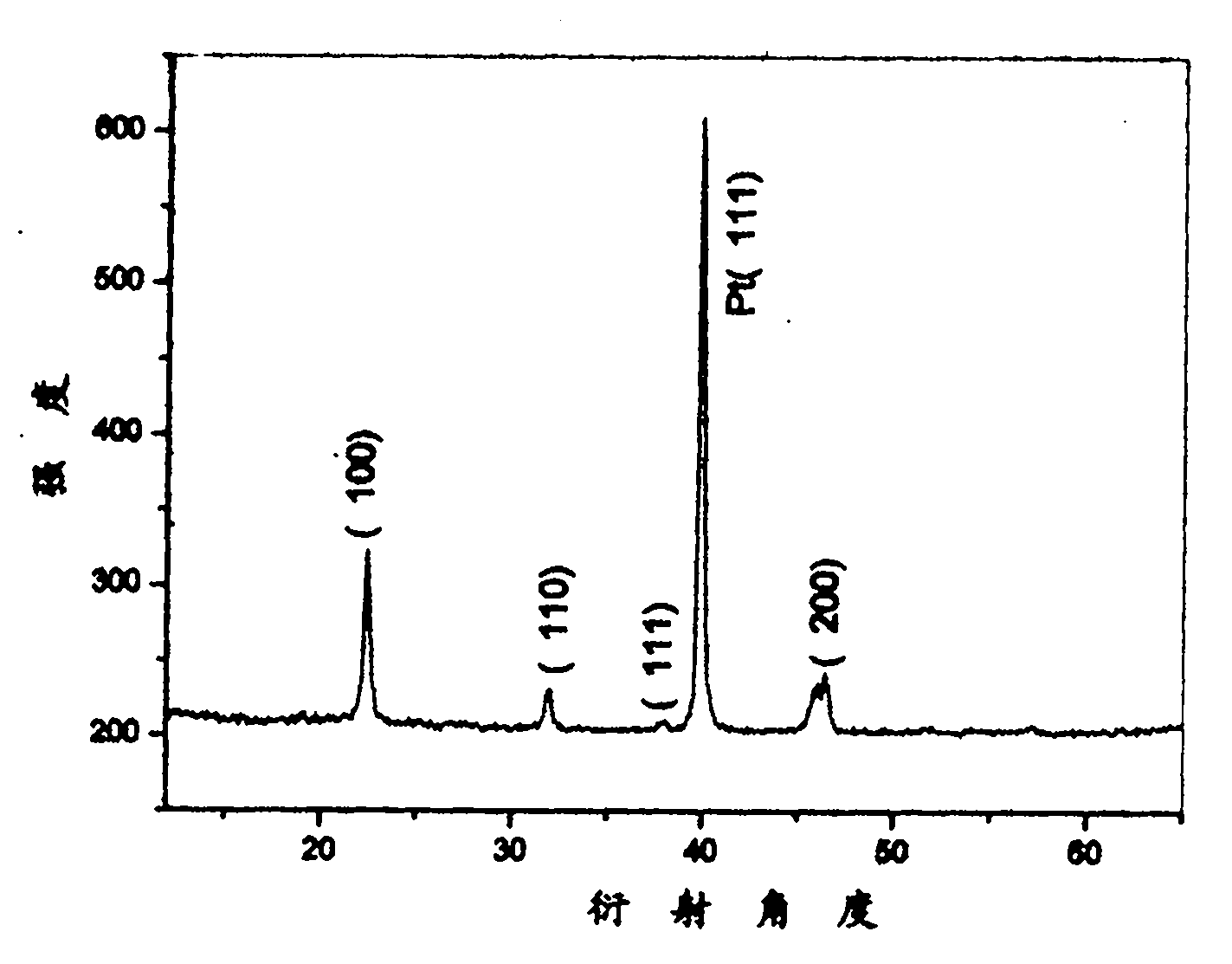

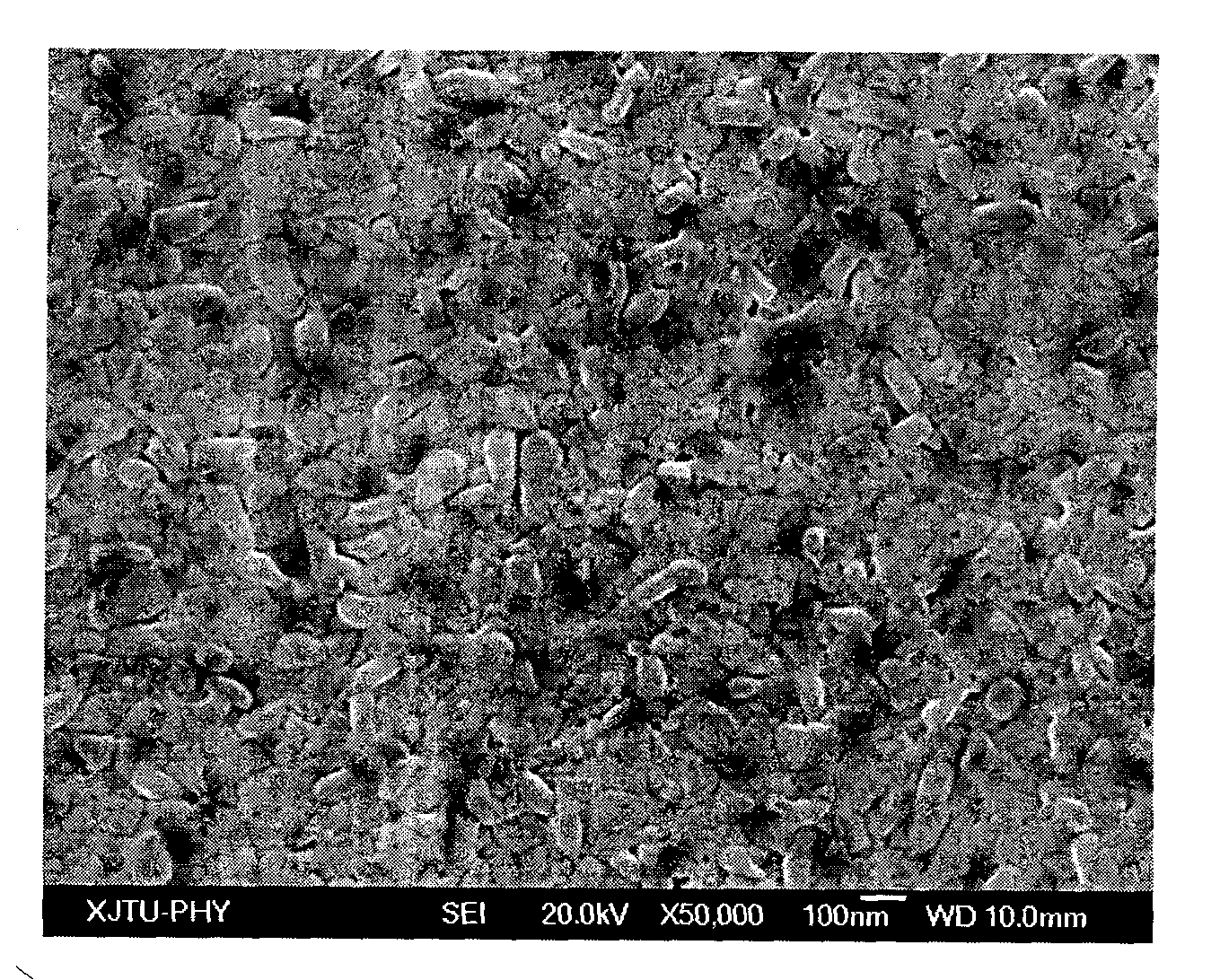

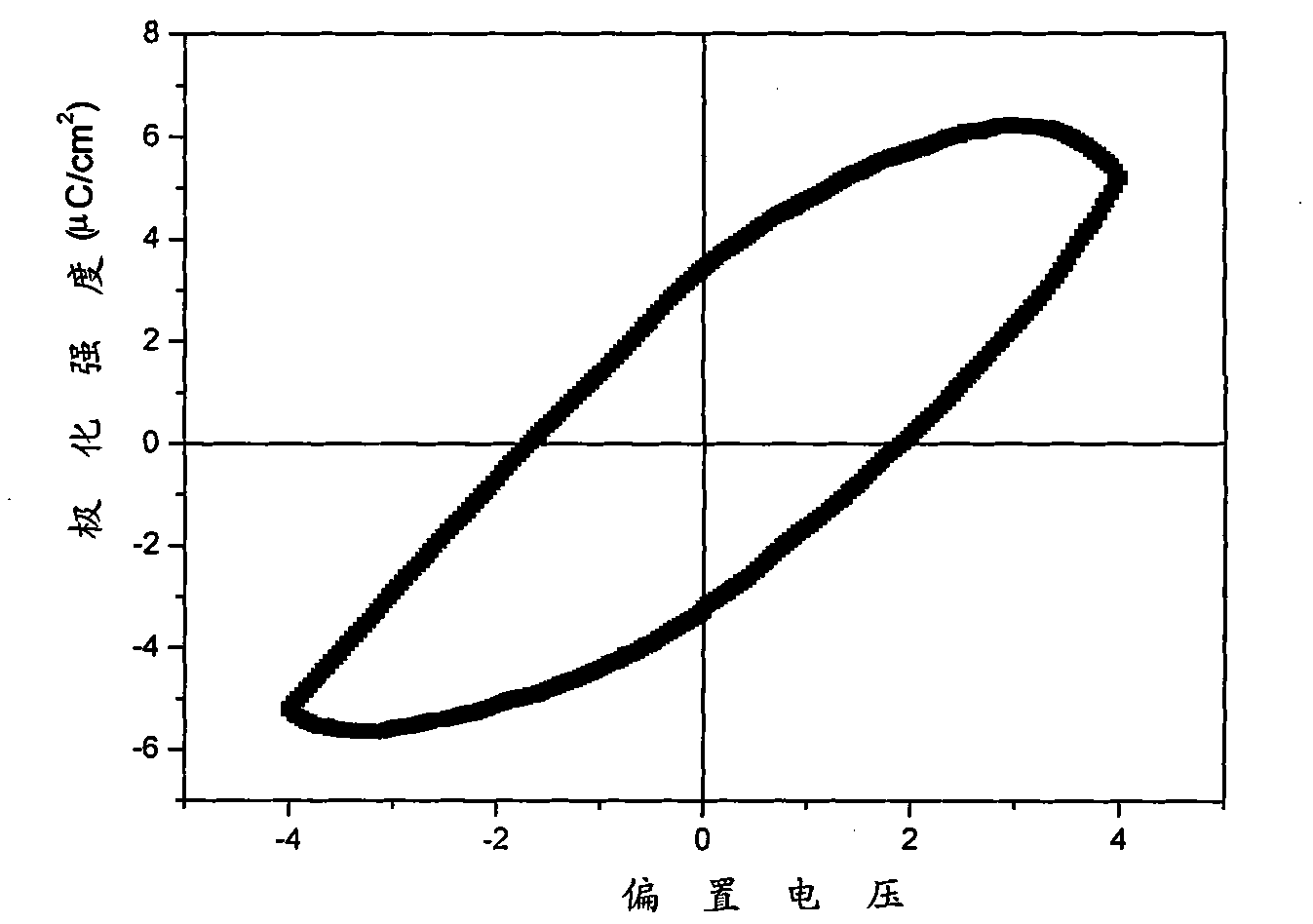

A potassium-sodium niobate, lead-free piezoelectric technology, applied in the fields of chemical instruments and methods, inorganic chemistry, niobium compounds, etc., can solve problems such as the unobtainable properties of potassium-sodium niobate thin film, instability of potassium-sodium niobate precursor solution, etc. , to achieve good preferred orientation, not easy to hydrolyze, dense and uniform crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Molar ratio NbCl 5 : Ethanol = 1: 10 Weigh anhydrous niobium pentachloride and absolute ethanol respectively, use anhydrous benzene as the reaction solvent, and then feed ammonia gas for 3 hours, and the obtained white precipitate NH 4 Cl suction filtration, the obtained filtrate was washed with benzene, and the benzene and excess absolute ethanol were removed by normal pressure distillation to obtain a yellow transparent niobium ethanol solution.

[0018] According to Na 0.5 K 0.5 NbO 3 Potassium, sodium and niobium molar ratio Na:K:Nb=0.5:0.5:1 ratio, first take anhydrous sodium acetate and anhydrous potassium acetate, and be dissolved in acetic acid solution, obtain potassium-sodium mixed solution; Next, take the niobium ethanol solution and dissolve it in the ethylene glycol methyl ether solution to obtain a niobium-containing solution. Mix the potassium-sodium-containing mixed solution obtained above with the niobium-containing solution, heat to 100° C., and st...

Embodiment 2

[0021] Molar ratio NbCl 5 : Ethanol = 1: 14 Weigh anhydrous niobium pentachloride and absolute ethanol respectively, use anhydrous benzene as the reaction solvent, and feed ammonia gas for 3 hours, and the obtained white precipitate NH 4 Cl suction filtration, the obtained filtrate was washed with benzene, and the benzene and excess absolute ethanol were removed by normal pressure distillation to obtain a yellow transparent niobium ethanol solution.

[0022] According to Na 0.5 K 0.5 The molar ratio of potassium, sodium and niobium in NbO3 is Na:K:Nb=0.5:0.5:1, first weigh anhydrous sodium acetate and anhydrous potassium acetate, dissolve them in acetic acid solution, and obtain a mixed solution containing potassium and sodium ; Next, take niobium ethanol solution and dissolve it in ethylene glycol methyl ether solution to obtain niobium-containing solution. Mix the potassium-sodium-containing mixed solution obtained above with the niobium-containing solution, heat to 100° ...

Embodiment 3

[0025] Molar ratio NbCl 5 : Ethanol = 1: 16 Weigh anhydrous niobium pentachloride and absolute ethanol respectively, use anhydrous benzene as the reaction solvent, and feed ammonia gas for 4 hours, and the obtained white precipitate NH 4 Cl suction filtration, the obtained filtrate was washed with benzene, and the benzene and excess absolute ethanol were removed by normal pressure distillation to obtain a yellow transparent niobium ethanol solution.

[0026] According to Na 0.5 K 0.5In NbO the molar ratio Na:K:Nb=0.5:0.5:1 ratio of sodium potassium and niobium in NbO, at first take by weighing anhydrous sodium acetate and anhydrous potassium acetate, be dissolved in the acetic acid solution, obtain the mixed solution containing potassium sodium; Next, take the niobium ethanol solution and dissolve it in the ethylene glycol methyl ether solution to obtain a niobium-containing solution. Mix the potassium-sodium-containing mixed solution obtained above with the niobium-contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com