Battery lead wire and manufacturing method

A lead wire, battery technology, applied in cable/conductor manufacturing, manufacturing tools, battery pack components, etc., can solve the problems of poor weldability, rising pure nickel prices, scarcity of nickel materials, etc., to reduce production costs and improve composite materials. Strength, the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] According to the present invention, copper metal has high electrical conductivity, while steel materials have low price and low production cost, especially after welding stainless steel materials, they have the advantages of firm welding with the shell and electrodes, smooth and clean weld seam surface, and smooth solder joints. The feature of rusting provides a battery lead wire composed of stainless steel, nickel and copper, which can replace the existing lithium battery lead wire made of pure nickel material, reduce manufacturing costs, and at the same time ensure that the battery lead wire Various properties required electrical conductivity, thermal conductivity, electrical resistance.

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

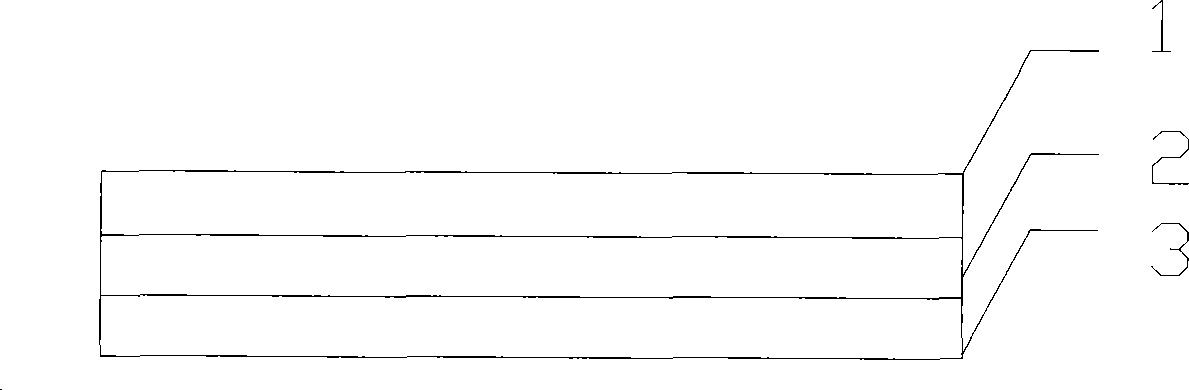

[0032] see figure 1 , The lead-out wire of the battery of the present invention is specifically made of stainless steel 1, nickel 2, copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com