Feeding complex enzyme preparation by fermentation of dextran waste liquor

A technology of compound enzyme and dextran for feed, applied in the directions of enzymes, enzymes, applications, etc., can solve the problems of high energy consumption and high cost of treatment, and achieve the effects of improving species and activity and reducing treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

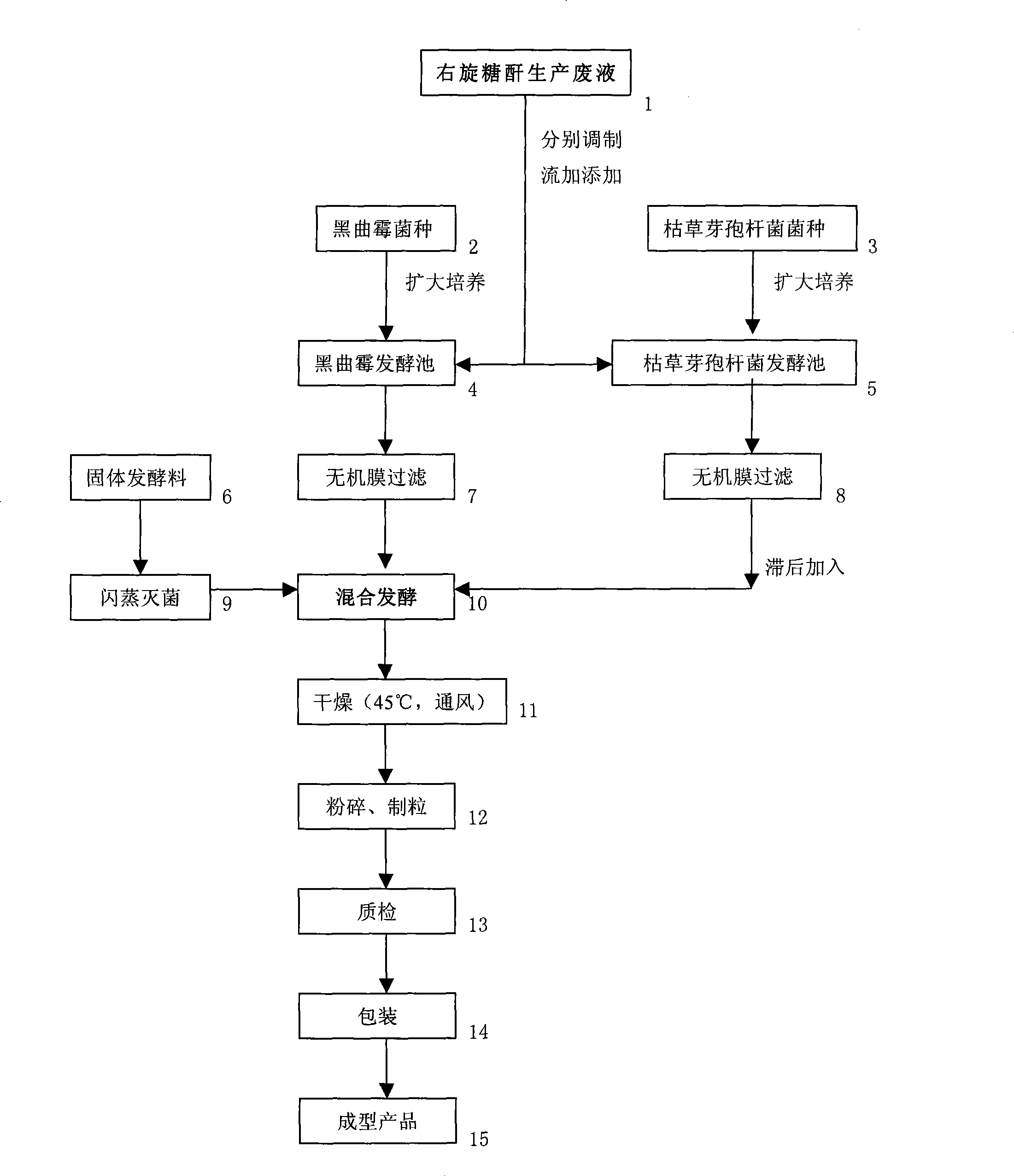

Method used

Image

Examples

Embodiment 1

[0016] Example 1: 1000L of dextran waste liquid, adjusted to pH 5.0-6.0, pumped into a 1500L liquid fermenter, extinguished for 2 hours, inserted into Aspergillus niger at a volume ratio of 1:10-30, kept warm and ventilated for fermentation 7 days. Mix the Aspergillus niger fermented liquid with the steam-sterilized bran at a weight ratio of 1:1.3, put it in a ventilated fermentation tank for fermentation for 7-10 days, dry at 45°C, and pulverize to obtain the enzyme product. After measurement, acid protease activity is 4000U / g, cellulose (CMC) enzyme activity is 12000U / g, pectinase activity is 20000U / g, xylanase activity is 10000U / g, β-glucanase activity is 10000U / g, starch Enzyme activity 600U / g.

Embodiment 2

[0017] Embodiment 2: Dextran waste liquid 1000L, add KH 2 PO 4 , 1Kg; (NH 4 ) 2 SO 4 , 0.5Kg; CaCl 2 , 0.3Kg; MgSO 4 ·7H 2 O, 0.3Kg; FeSO 4 ·7H 2 O, 50g; MnSO 4 4H 2 O, 16g; ZnSO 4 ·7H 2 O, 14g; adjust the pH to 5.0-6.0, pump it into a 1500L liquid fermentation tank, and insert it into the Aspergillus niger strain at a volume ratio of 1:10-30 for 2 hours, heat preservation and aeration for 7 days. Mix the Aspergillus niger fermented liquid with the steam-sterilized bran at a weight ratio of 1:1.3, put it in a ventilated fermentation tank for fermentation for 7-10 days, dry at 45°C, and pulverize to obtain the enzyme product. After measurement, acid protease activity is 4000U / g, cellulose (CMC) enzyme activity is 20000U / g, pectinase activity is 50000U / g, xylanase activity is 20000U / g, β-glucanase activity is 20000U / g, starch Enzyme activity 400U / g.

Embodiment 3

[0018] Embodiment 3: Dextran waste liquid 1000L, add KH 2 PO 4 , 1Kg; (NH 4 ) 2 SO 4 , O.5Kg; CaCl 2 , O.3Kg; MgSO 4 ·7H 2 O, 0.3Kg; FeSO 4 ·7H 2 O, 50g; MnSO 4 4H 2 O, 16g; ZnSO 4 ·7H 2O, 14g; adjust the pH to 7.0-8.0, pump it into a 1500L liquid fermentation tank, and insert it into the Bacillus subtilis strain at a volume ratio of 1:10-30 for 2 hours, keep it warm at 38°C, and ferment with aeration for 3 days. After membrane filtration, the volume is concentrated to 120L, mixed with fermented Aspergillus niger solid fermentation material, the weight ratio is 1:1.3-1.5, mixed evenly, fermented at 23-26°C for 1-3 days, dried at 45°C, and crushed Enzyme products. After measurement, acid protease activity is 6500U / g, cellulose (CMC) enzyme activity is 22000U / g, pectinase activity is 60000U / g, xylanase activity is 25000U / g, β-glucanase activity is 28000U / g, starch The enzyme activity is 800U / g, and the viable count of Bacillus subtilis is 2.3×10 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com