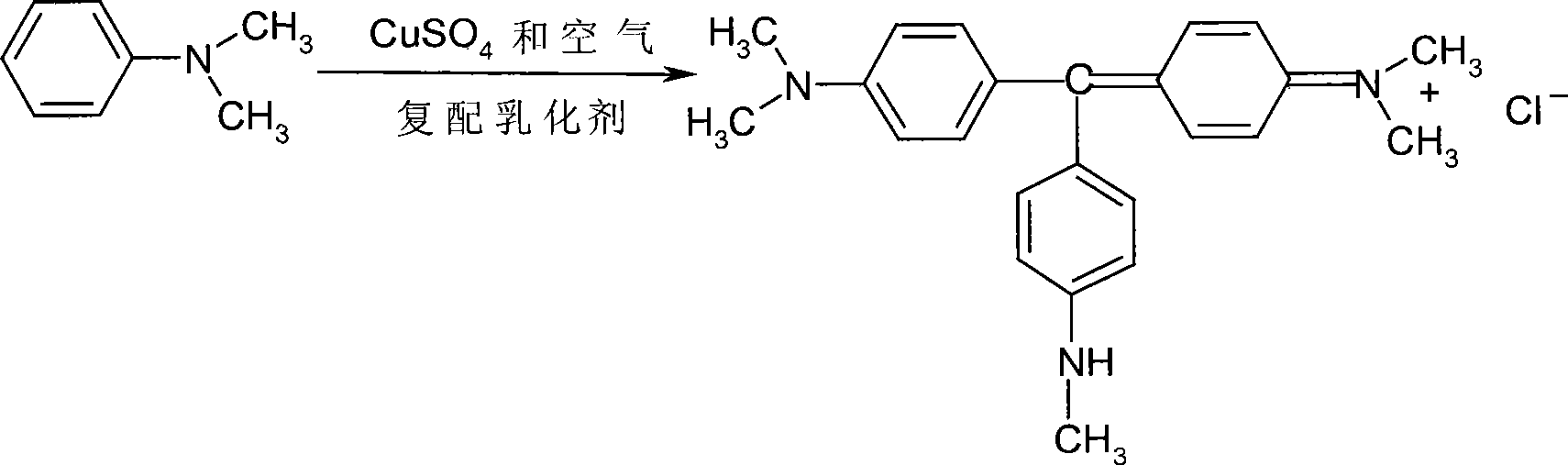

Synthetic technology of phenol-free alkali violet

A synthetic process and basic technology, which is applied in the catalytic oxidation synthesis of phenol-free basic violet dye, and in the field of phenol-free basic violet synthesis process, can solve the problems of high cost, hard oxidized material, low yield, etc., and reduce the recovery Copper cost, reduced emissions, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Take 160ml of N,N-dimethylaniline aqueous solution (containing about 50g of N,N-dimethylaniline), take 5g of AEO-7, 10g of chlorobenzene, 27g of salt, and 30g of copper sulfate crystals into the solution. Stir vigorously at 50-80°C and blow in air, while adding acetic acid dropwise to keep acidic, and react for 40-45 hours. The oxidation material is golden and brittle at room temperature as the end of the reaction. Add 200ml of chlorobenzene and 100ml of liquid caustic soda and heat to 100°C, stir for 3 hours, filter, stand for separation, let go of the water layer, treat the organic layer with dilute hydrochloric acid, discard the organic phase, and obtain 45g of dye. The dye strength is determined to be 100. The yield is more than 95%.

Embodiment 2

[0026] Example 2: Take 160ml of N,N-dimethylaniline aqueous solution (containing about 50g of N,N-dimethylaniline), take 4g of AEO-12, 10g of chlorobenzene, 27g of salt, and 30g of copper sulfate crystals into the solution, Stir vigorously at 50-80°C and blow in air while adding acetic acid dropwise to keep acidic. The reaction is 40-45 hours. The oxidation material is golden and brittle at room temperature, which is the end of the reaction. The oxidation material treatment method is the same as that of Example 1, and 46 g of dye is obtained. , The dye intensity is 100 points after testing. The yield is more than 95%.

Embodiment 3

[0027] Example 3: Take 160ml of N,N-dimethylaniline aqueous solution (containing about 50g of N,N-dimethylaniline), take 5g of AN1810, 10g of chlorobenzene, 27g of salt, and 30g of copper sulfate crystals into the solution. Stir vigorously at ~80°C and blow in air, while adding acetic acid dropwise to keep acidic, react for 40-45 hours. The oxidation material is golden and brittle at room temperature as the end of the reaction. The oxidation material treatment method is the same as that in Example 1, to obtain 43g of dye. The detection dye intensity is 100 points. The yield is more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com