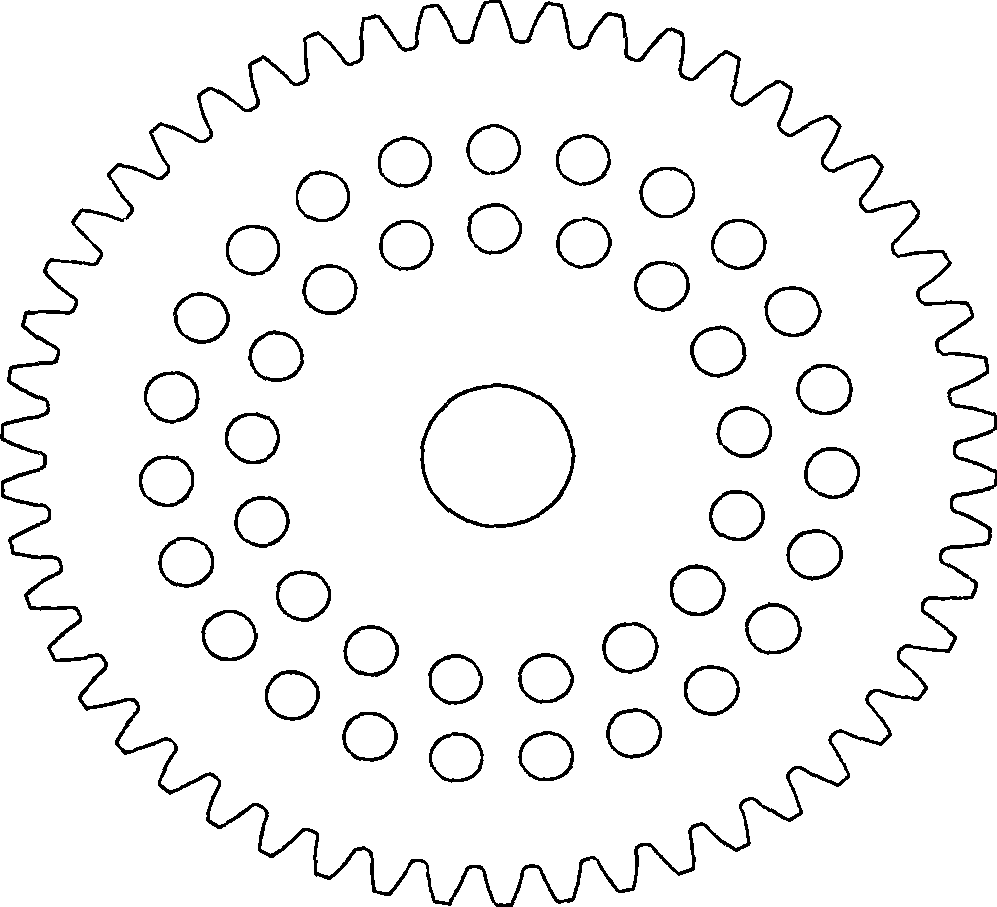

Production process of Planetary gear sheet etching method

The invention relates to a production process and a technology of a planetary wheel, which is applied to the production process of the etching method of a planetary wheel for grinding, and can solve the problems of low machining accuracy, affecting product yield, and burrs on product edges, so as to achieve high machining accuracy and improve yield. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

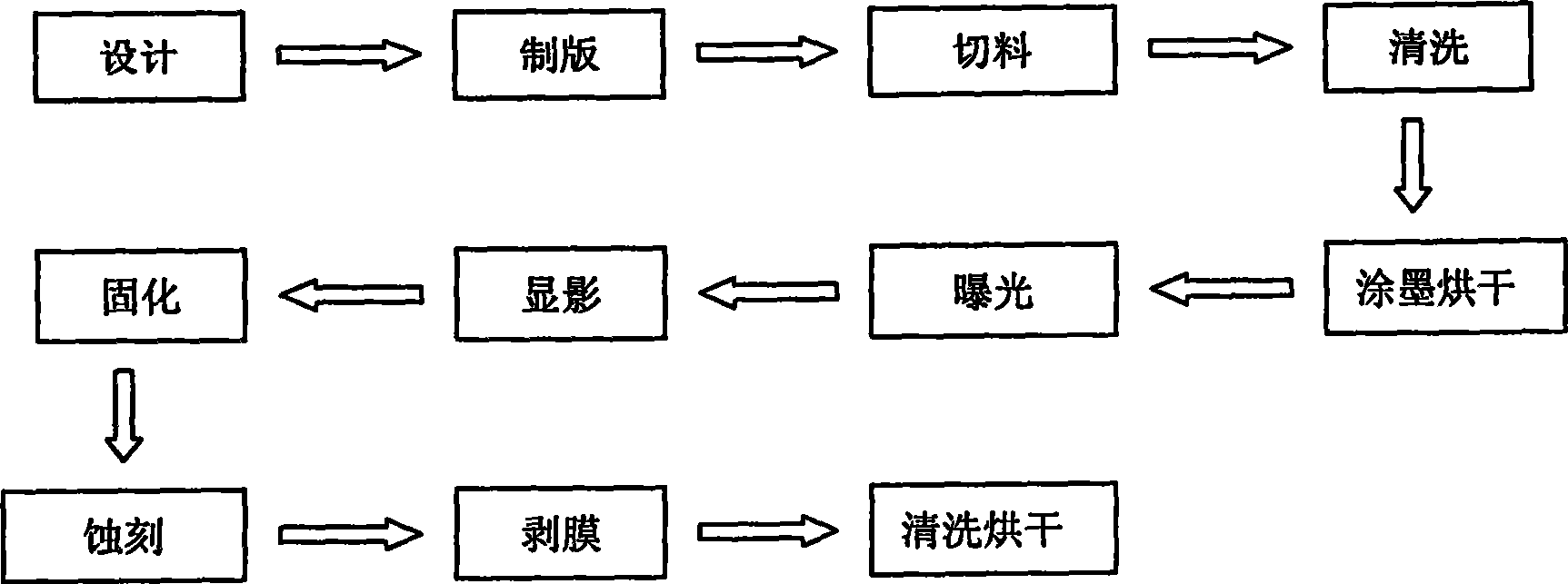

[0030] Referring to accompanying drawing: embodiment technological process of the present invention is:

[0031] 1. Design:

[0032] Using CAD drawing, plate making is calculated according to A=T / 2, where A is the corrosion allowance, and T is the thickness of the raw material;

[0033] 2. Plate making:

[0034] Use a photoplotter to make the film, align it under a 100X microscope, and the alignment deviation does not exceed 5 μm;

[0035] 3. Feeding:

[0036] Use a shearing machine to cut the coiled material into the required plate size for the product;

[0037] 4. Cleaning:

[0038] Degrease the cut plate with cleaning agent, and then wash it with water;

[0039] 5. Photosensitive material coating:

[0040] Ink is applied to the plate after cleaning and drying with a screen process, and the ink layer is photosensitive resist ink. After the ink coating on the first side is completed, it enters the infrared dryer for transmission drying. The temperature range of the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com