Method for improving aeolotropism magnetic resistance permalloy film performance

An anisotropic magnetic and permalloy technology, which is applied in the manufacture/processing of electromagnetic devices, metal material coating technology, ion implantation plating, etc., can solve problems such as unfavorable AMR device applications, and achieve low crystal anisotropy , high anisotropic magnetoresistance value, low coercive force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

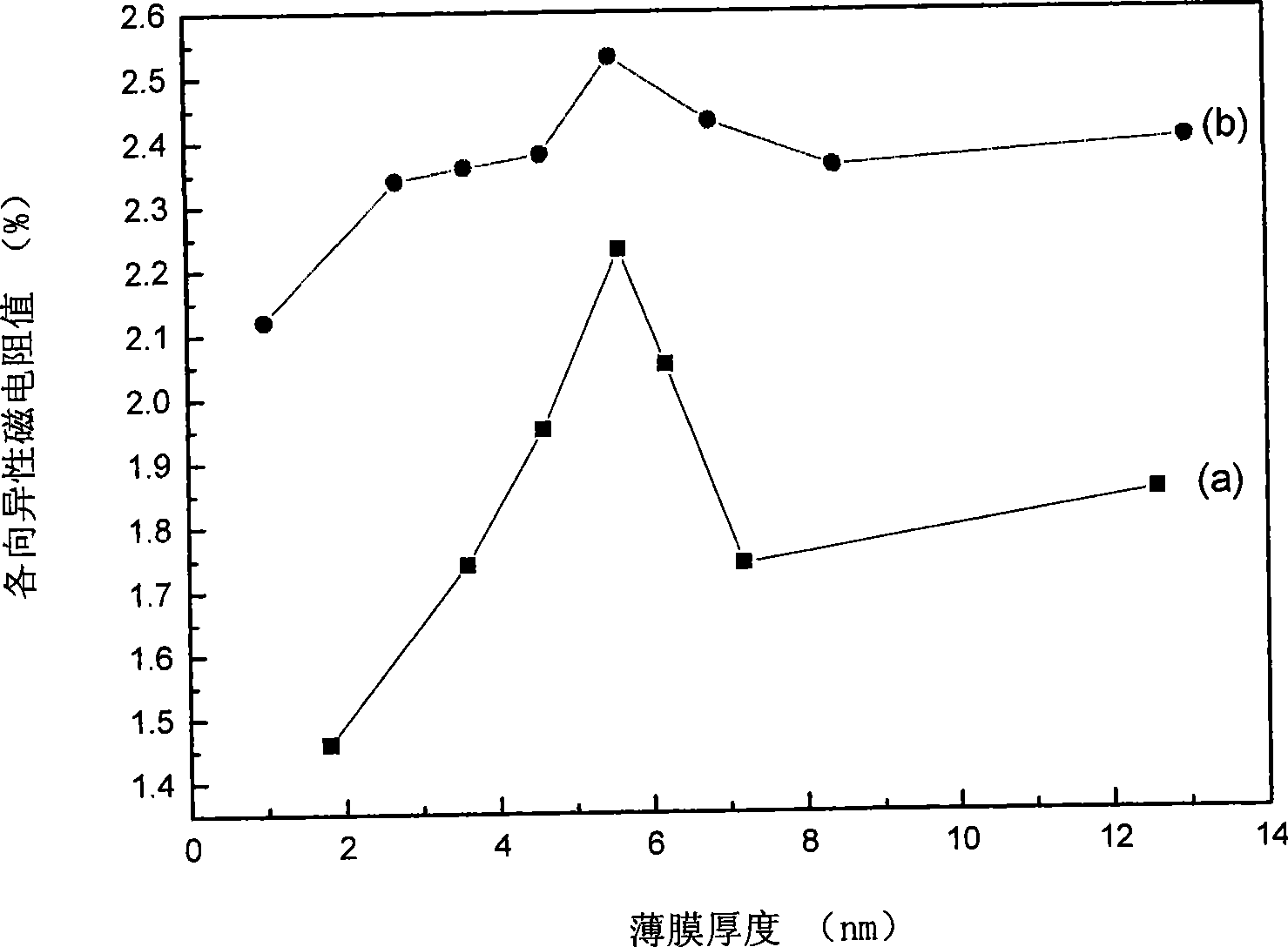

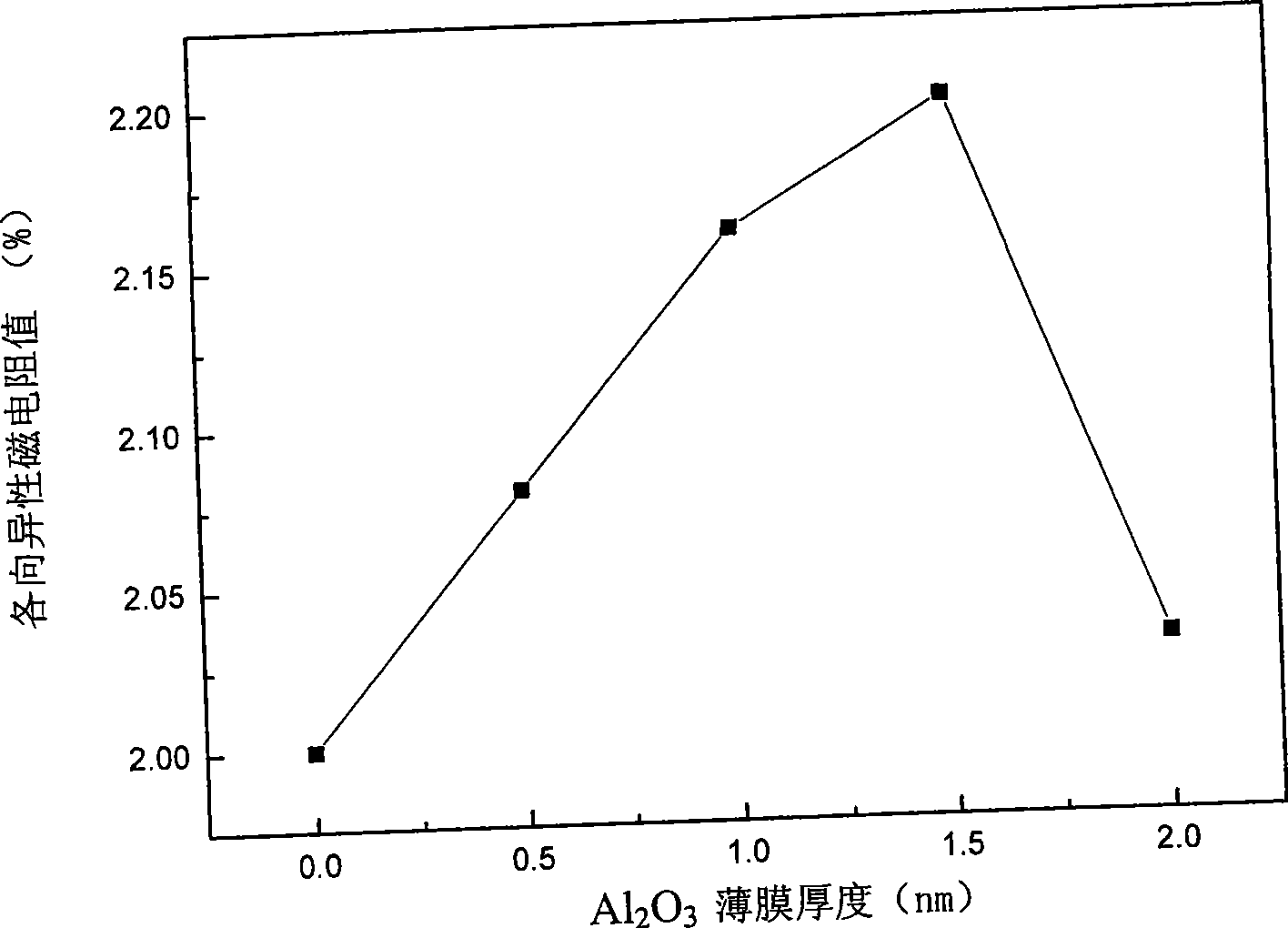

specific Embodiment approach

[0012] Specific embodiments: anisotropic permalloy Ni is prepared in a magnetron sputtering apparatus 81 Fe 19 film. First, the glass substrate is ultrasonically cleaned with organic chemical solvents and deionized water, and then placed on the sample base of the sputtering chamber. The substrate is cooled with circulating deionized water, a magnetic field of 250 Oe is applied parallel to the direction of the substrate, and the substrate is always rotated at a rate of 18 revolutions per minute, and the sputtering deposition rate is 0.17 nm / min. Sputtering chamber background vacuum 4×10 -5 Pa, 99.99% pure argon gas was passed into the coating chamber for 0.5 hours before sputtering, and the pressure was maintained at 0.3Pa. Deposit 6nm-thick Ta / 50.0nm-thick Ni sequentially under the condition of high-purity argon gas with 99.99% purity during sputtering at a pressure of 0.4Pa y Fe 100-y . by 50.0nmNi y Fe 100-y Chemical analysis to find out the corresponding Ni when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com