Recording type compact disc production line

A production line and optical disc technology, applied in the direction of optical record carrier, optical record carrier manufacturing, etc., can solve the problems of complex production line structure, large footprint, deformation of optical disc substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

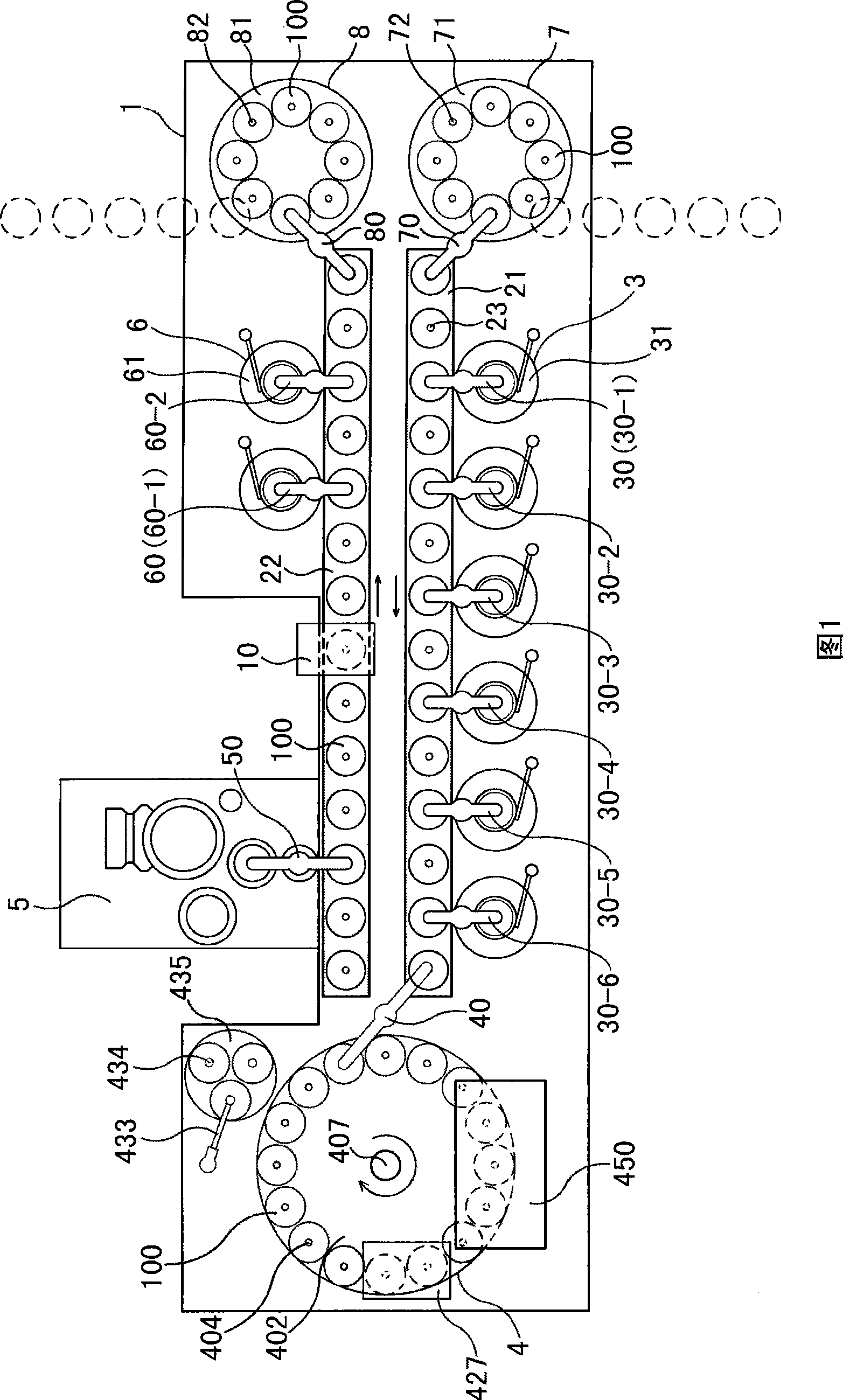

[0045]As shown in FIG. 1 , this recordable optical disc production line includes a frame 1 on which a conveyor belt is arranged. In this embodiment, the conveyor belt includes two conveyor belt sections 21, 22, each of which is composed of a driving pulley, a driven pulley and a transmission belt, and the conveyor belt sections 21, 22 are synchronous gears. shaped belt, the front end of the latter conveyor belt section 22 is continuous with the rear end of the previous conveyor belt section 21, the previous conveyor belt section 21 and the latter conveyor belt section 22 are parallel to each other and arranged side by side, and the latter conveyor belt section 22 transports the optical disc substrate The direction of the sheet 100 is opposite to the previous conveyor belt section 21 (direction as shown by the arrow in Figure 1); the transmission belt is provided with a plurality of disc substrate placement seats 23, and the disc substrate placement seats 23 on each transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com