Use of carbonyl reductase in (S)-4-chloro-3 hydroxy butyric ether production

A technology of ethyl hydroxybutyrate and carbonyl reductase, which is applied in the direction of oxidoreductase, fermentation, etc., to achieve the effects of high yield, low production cost and high optical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

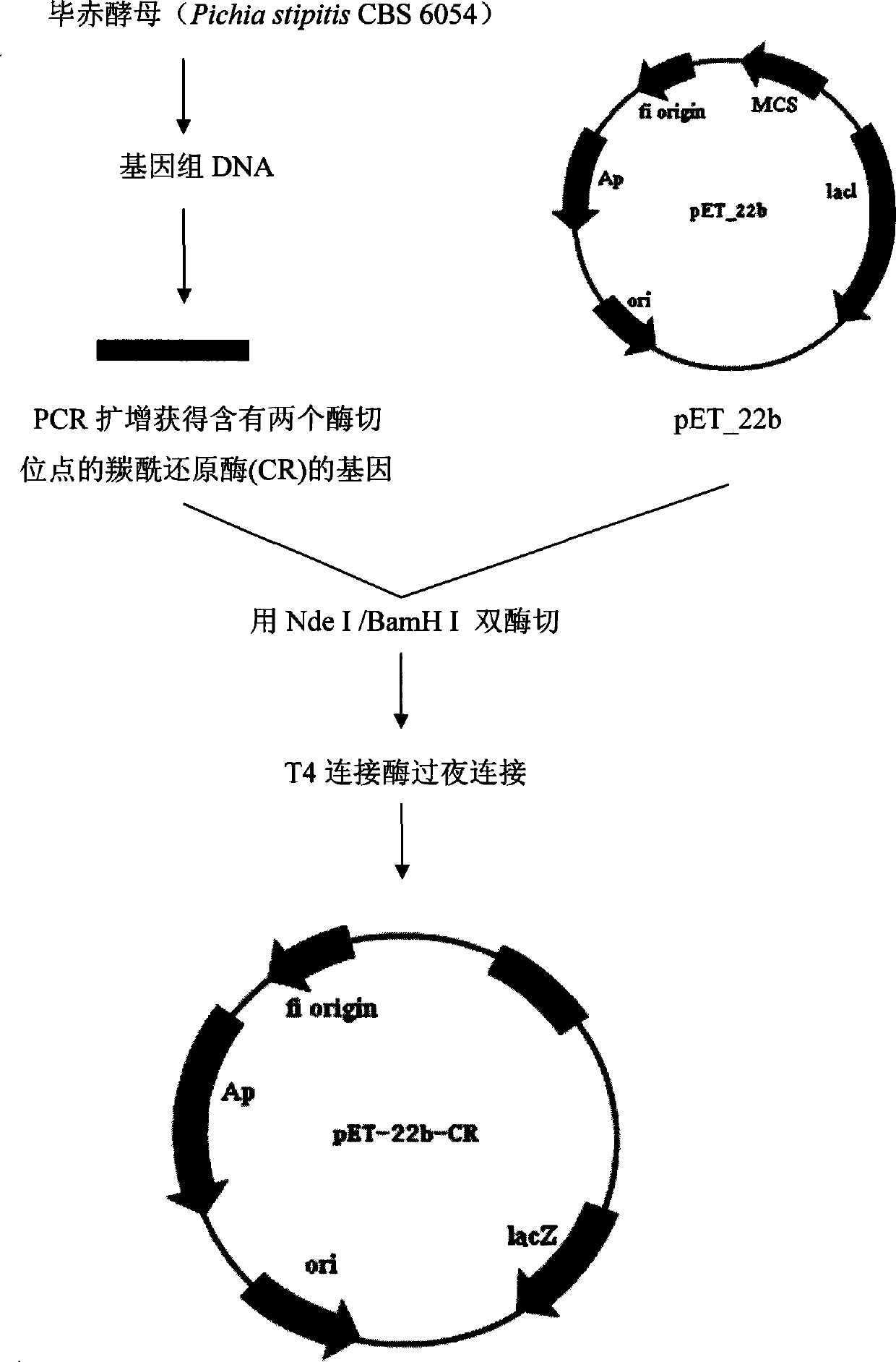

[0026] Example 1: Construction of recombinant Escherichia coli E.coli Rosseta (pET22b-PsCR)

[0027] 1. Acquisition of carbonyl reductase gene

[0028] Pichia Stipitis CBS 6054 (purchased from Centraalbureau voor Schimmelcultures (CBS) Fungal Biodiversiry Centre), medium YPD (g L -1 ): Yeast extract 10g, peptone 20g, glucose 20g, add distilled water to 1L.

[0029] Pichia Stipitis CBS 6054 was inoculated in 5mL LYPD liquid medium and cultured at 30°C to logarithmic growth phase, and the genome was extracted using a genomic DNA extraction kit (Beijing Tianwei Bioengineering Co., Ltd. Yeast Genome Extraction Kit).

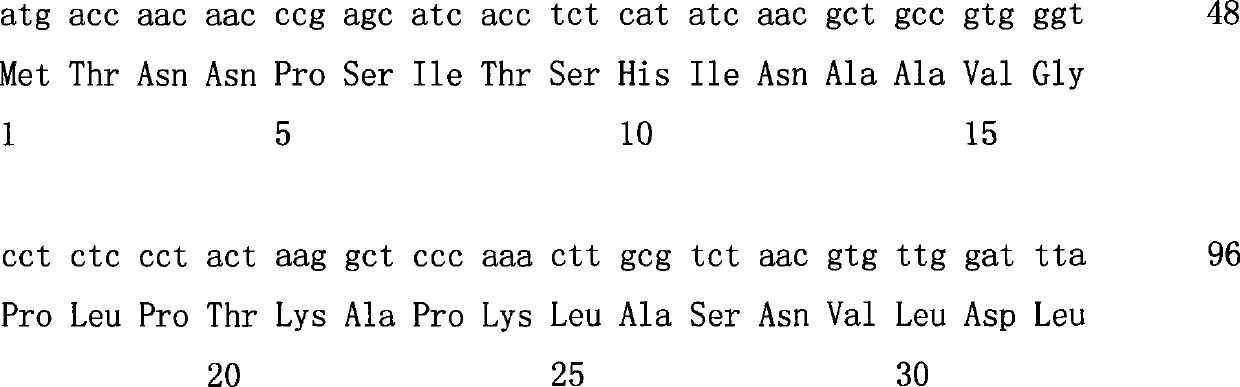

[0030] The primers used to construct the expression vectors are provided with enzyme cutting sites, and the primer sequences are as follows:

[0031] The upstream primer (CR-sense contains Nde I) is: 5'GGAATTC CATATG ACCAACAACCCGAGCAT downstream primer (CR-anti containing BamH I) is: CGC GGATCC CTATGGCGCACAGTAGCCTCC

[0032] All primers were synthesized by Sha...

Embodiment 2

[0041] Embodiment 2: Fermentation of recombinant Escherichia coli E.coli Rosseta (pET22b-PsCR)

[0042] Pick the recombinant bacteria E.coli Rosseta (pET-22b-PsCR) into the LB culture medium containing antibiotics, and cultivate overnight at 37°C with shaking. Then inoculate into fresh culture medium according to 2% inoculum amount, and cultivate to OD at 37°C 600 At about 0.6, add IPTG to a final concentration of 0.8mmol·L -1 , 25°C, 220rpm, after induction of expression for 10h, centrifuge at 8000rpm, 4°C for 10min, discard the supernatant, and precipitate for later use.

Embodiment 3

[0044] The precipitate of Example 2 was washed twice with potassium phosphate buffer (100mmol·L-1, pH 6.5), weighed 0.5g (wet weight) of E. coli sludge, and suspended in 15mL of pH 6.5 potassium phosphate buffer. Cells were sonicated (power 300W, sonication 5s, intermittent 5s, 5min in total), glucose 200mmol / L, COBE 1.5g / L, GDH 50U, NADP 0.05mmol / L, 20°C, 180rpm, 16h. The yield of the product (S)-CHBE was 1.45 g / L, the yield of the product was: 96.7%, and the optical purity e.e% was 100%.

[0045] The detection method of product is as follows (the detection method of product is identical with embodiment 3 in the following examples):

[0046] For the aqueous phase reaction: after the reaction, add an equal volume of ethyl acetate, vibrate vigorously for 10 minutes, then place it for two hours, and centrifuge at 8000rpm for 10 minutes to separate the organic layer and the aqueous layer. Carefully draw the upper layer of ethyl acetate through the organic membrane, add the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com