Copper base sintered slide member

A technology of sliding parts and sintered layers, which is applied in the direction of anti-centrifugal force rotating parts, bearing elements, rolling resistance optimization, etc., to achieve the effect of excellent sliding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

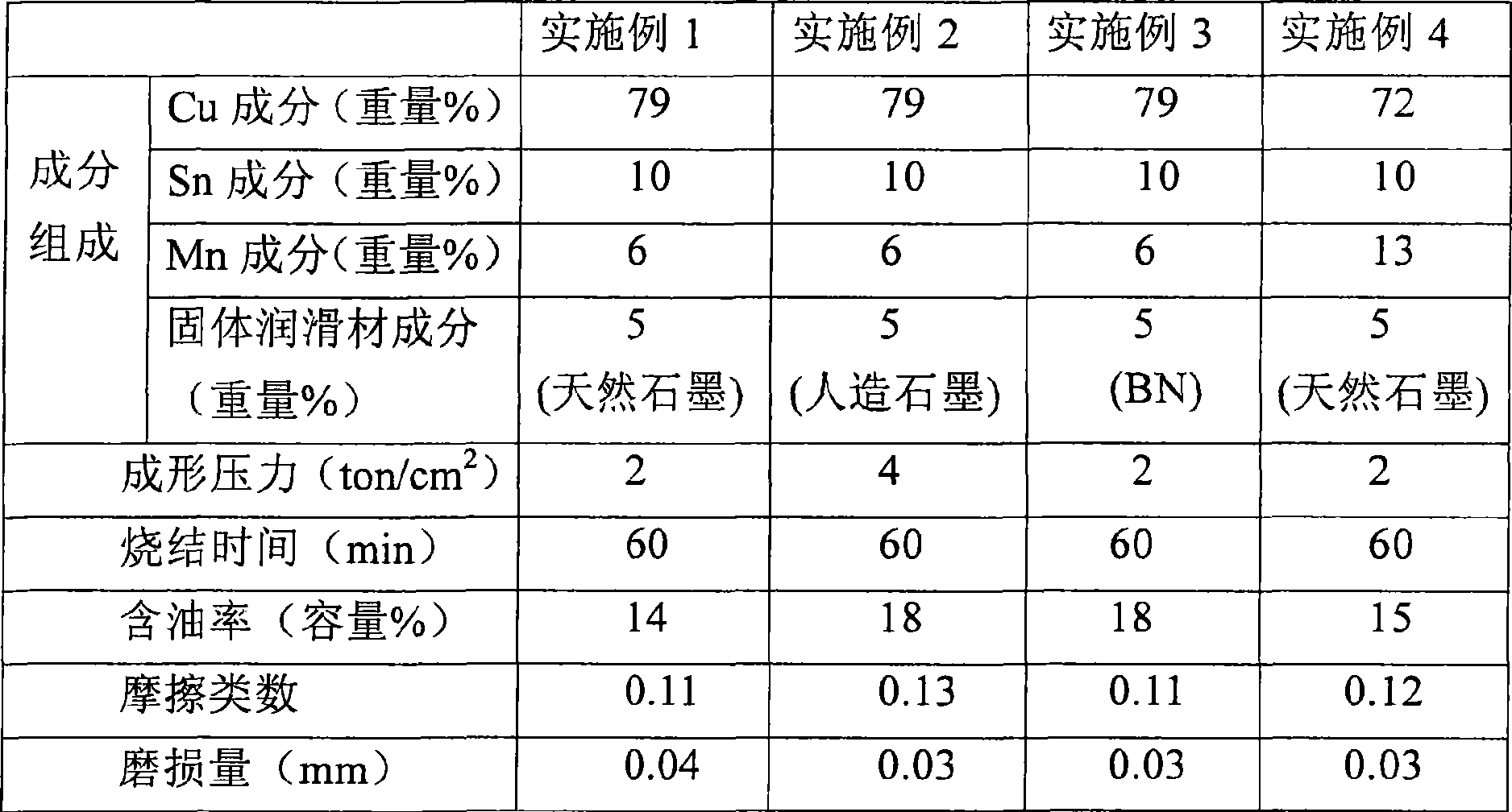

[0024] Among the electrolytic Cu powders with a particle size of 45μm or less, 10% by weight atomized Sn powder with a particle size of 45um or less, Mn powder with a particle size of 45μm or less and 6% by weight, and 5% by weight with a particle size of 150μm or less % Of natural graphite powder is put into the V-shaped mixer and mixed for 20 minutes to make a mixed powder. Fill the mixed powder in a metal mold at a molding pressure of 2ton / cm 2 Under compression molding, a flat plate-shaped compact is obtained. The compact was sintered in a heating furnace adjusted to a hydrogen atmosphere at a temperature of 760°C for 60 minutes. After cooling, it was machined to produce a square sintered sliding part with a side of 30 mm and a thickness of 5 mm. Next, the sintered sliding part is treated with oil to form an oily sintered sliding part.

Embodiment 2~5

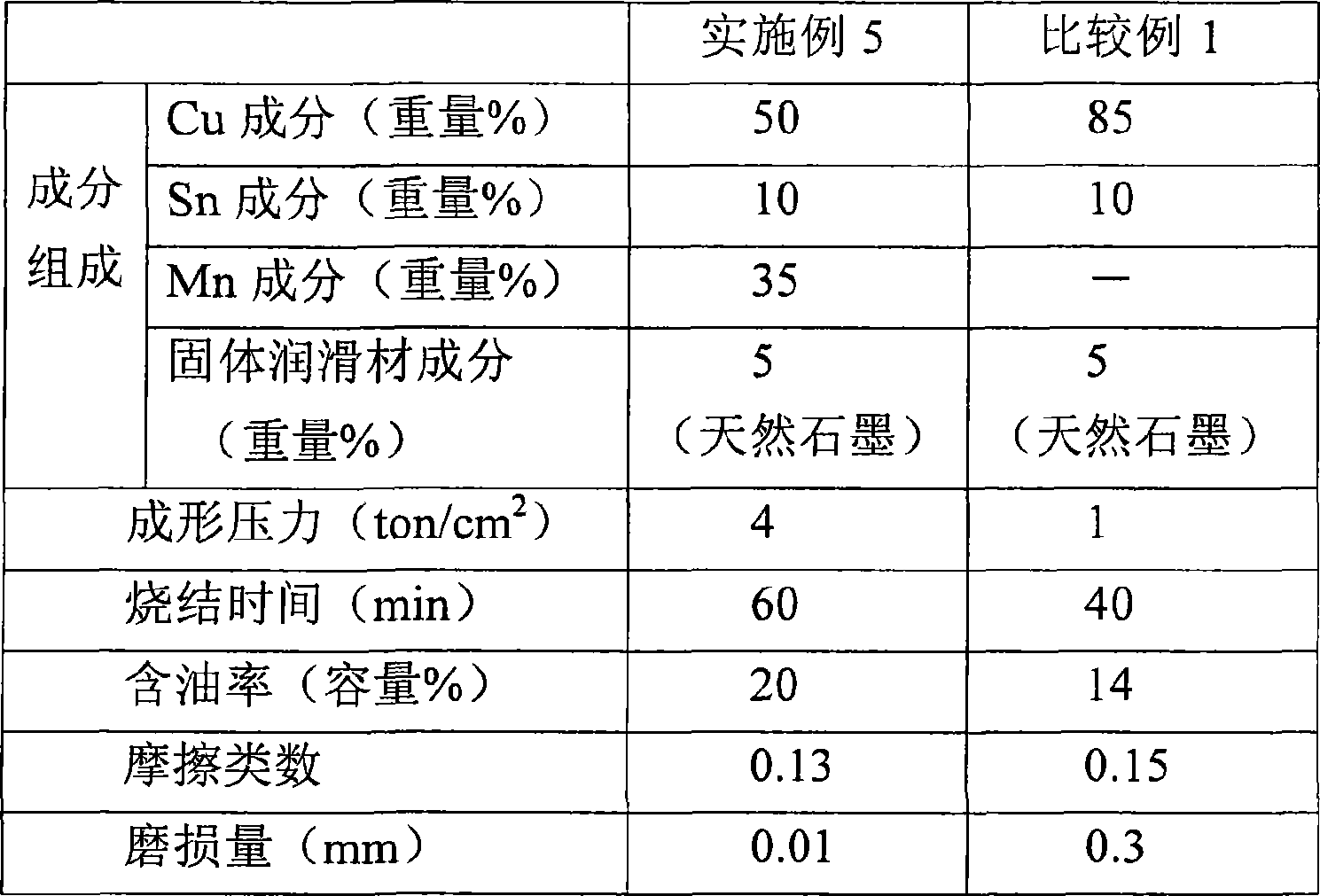

[0026] In Example 1, except for changing the composition as shown in Tables 2 to 3, an oil-impregnated sintered sliding part was produced in the same manner as in Example 1.

Embodiment 6

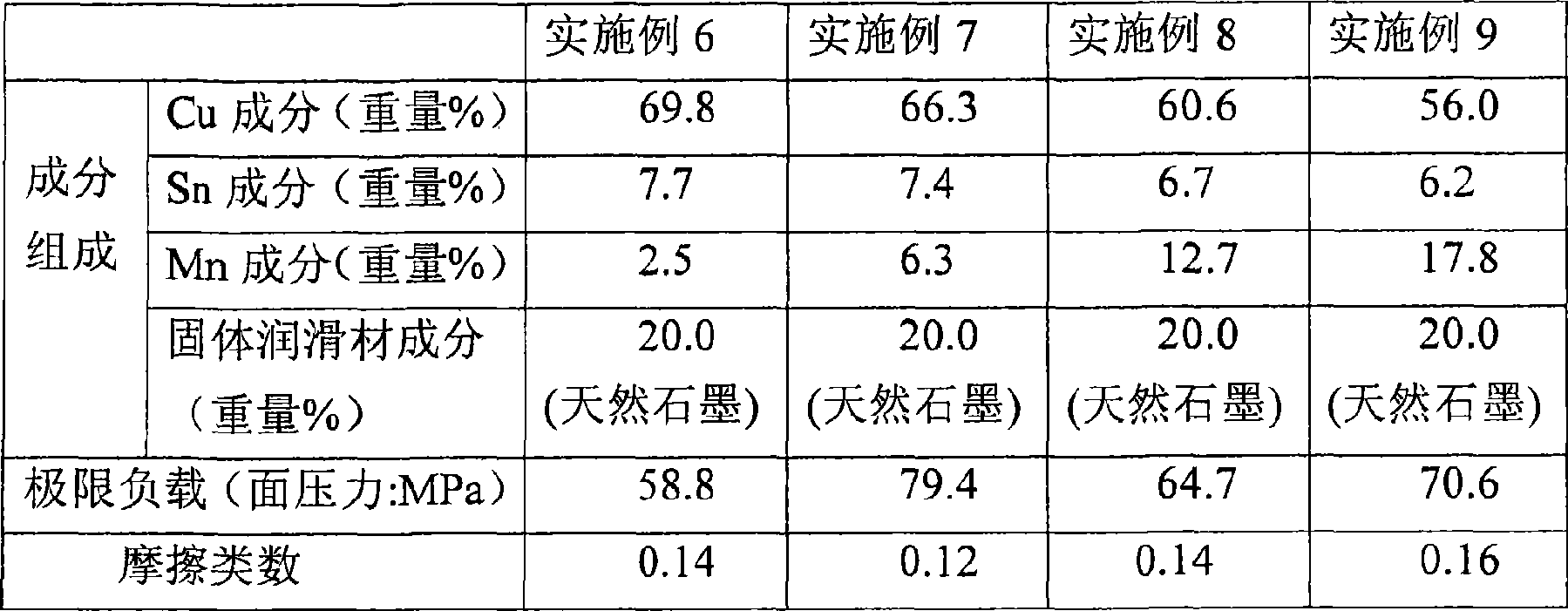

[0042] Put Cu-10wt% Sn atomized alloy powder with a particle size of 45μm or less, 2.5wt% Mn powder with a particle size of 45μm or less, and 20wt% natural graphite powder with a particle size of 150um or less into the V type In the mixer, the mixture was mixed for 20 minutes to prepare mixed powder (Cu: 69.8% by weight, Sn: 7.7% by weight, Mn: 2.5% by weight, and graphite: 20% by weight). Fill the obtained mixed powder in a metal mold at a molding pressure of 4ton / cm 2 Under compression molding, a flat plate-shaped compact is obtained. The compact was sintered in a heating furnace adjusted to a hydrogen atmosphere at a temperature of 760°C for 60 minutes, and after cooling, mechanical processing was performed to prepare a square sintered sliding part with a side of 30 mm and a thickness of 5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com