Stretch-blow molding apparatus and equipment of plastic material perform and application of ceramic member

A technology of plastic material and stretch blow molding, which is used in the equipment for stretch blow molding into plastic material containers, the device for stretch blow molding into plastic material containers, and the application field of functional components, which can solve the increase of wear and tear of composite plastic materials, etc. problem, to achieve the effect of high degree of stability and low thermal expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

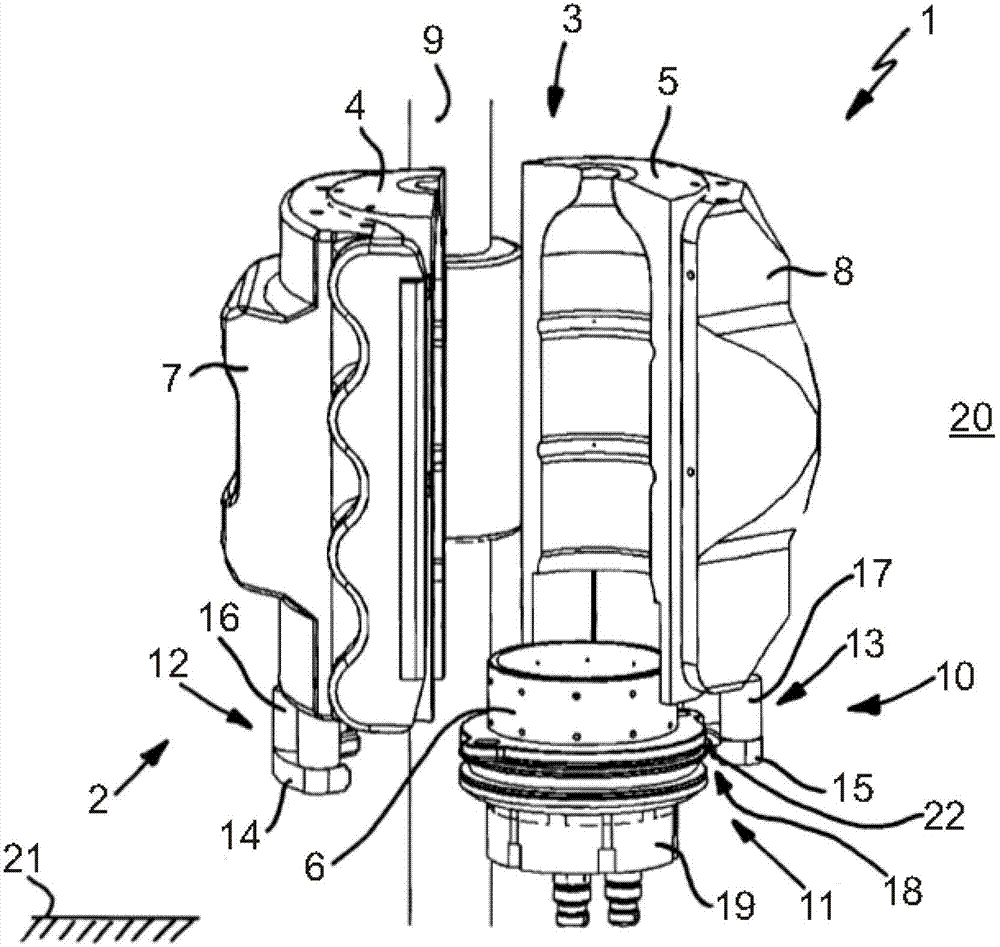

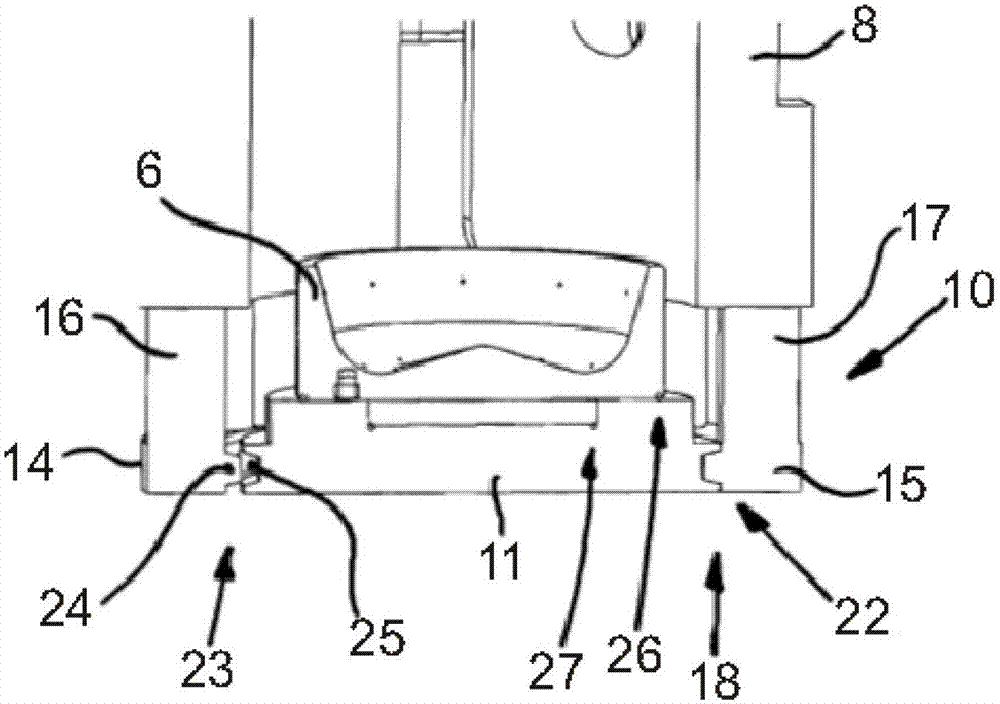

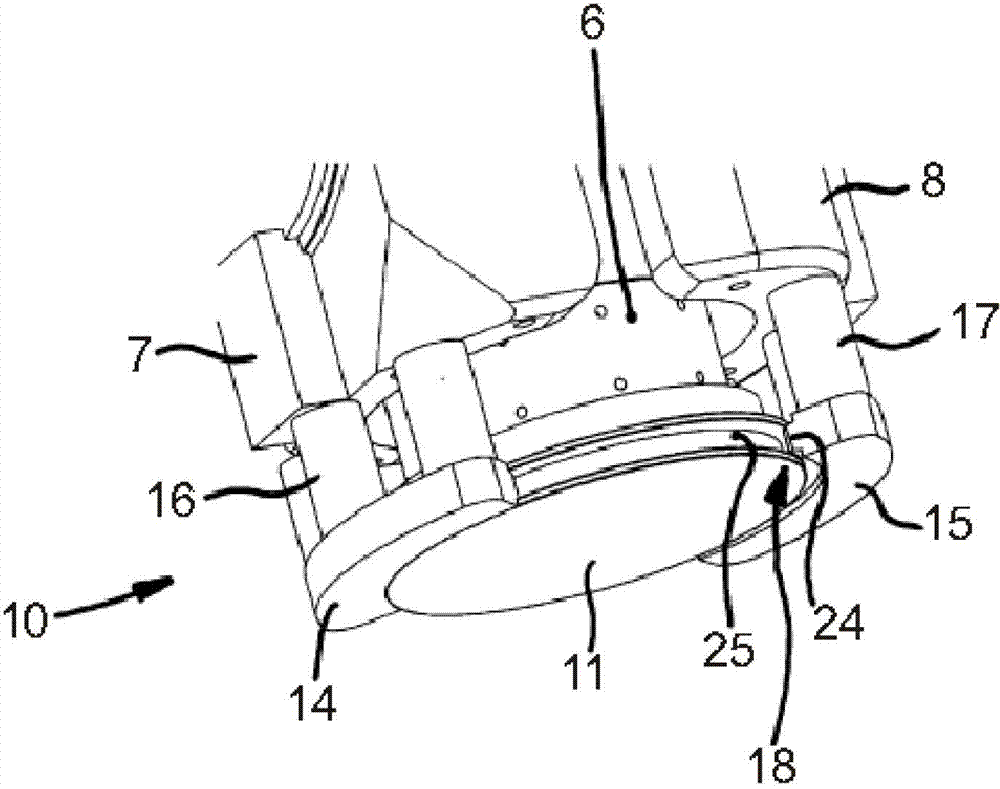

[0049] figure 1 A device for stretch blow molding plastics material pre-forms (not shown here) into plastics material containers (also not shown here) shown in comprises: a carrier assembly 2 for carrying a blow mold 3, The blow mold 3 essentially comprises a first side shell part 4, a second side shell part 5 and a base part 6, the two shell parts 4 and 5 and the base part 6 being used to shape a corresponding plastics material container.

[0050] The carrier assembly 2 is divided into two parts and has a first carrier assembly half 7 for carrying the first side shell part 4 and a second carrier assembly half 8 for carrying the second side shell part 5 . In this case, the two carrier assembly halves 7 and 8 are mounted on a carrier bar 9 so as to be pivotable relative to each other, so that the two side housing parts 4 and 5 can pass through the two carrier assemblies in a known manner. Halves 7 and 8 are opened and closed accordingly.

[0051] A base part clamping assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com