Method for displaying high-strength vessel slab original austenite crystal grain

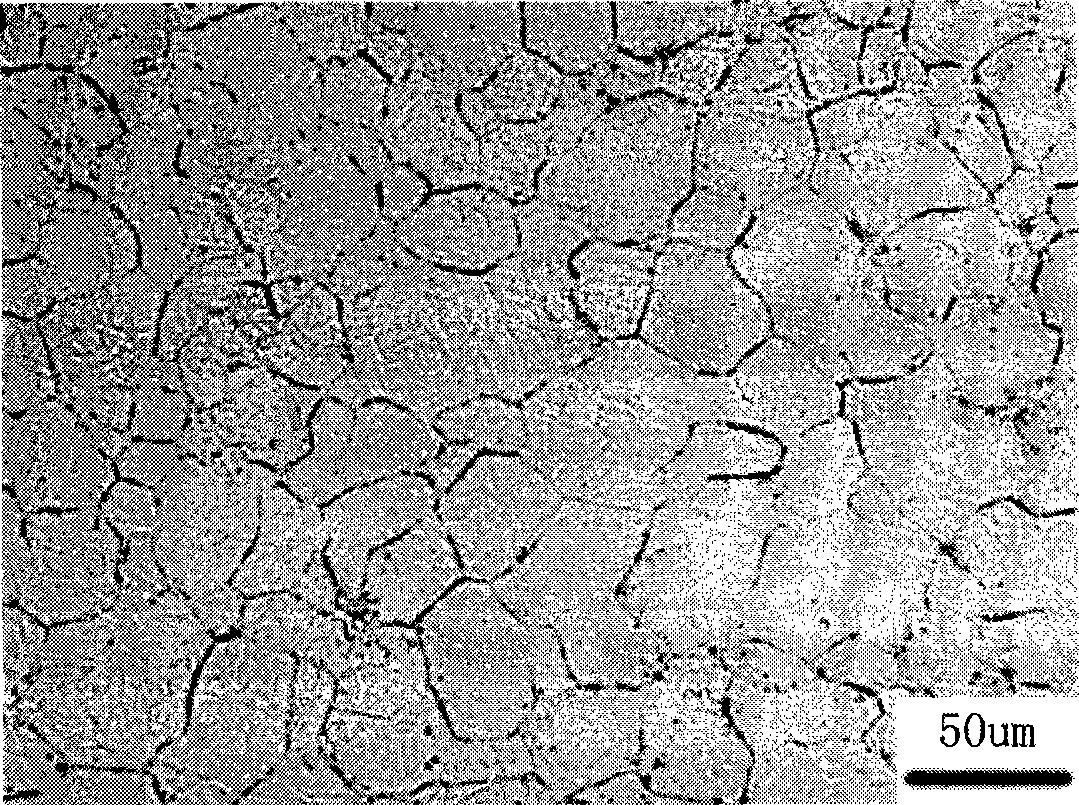

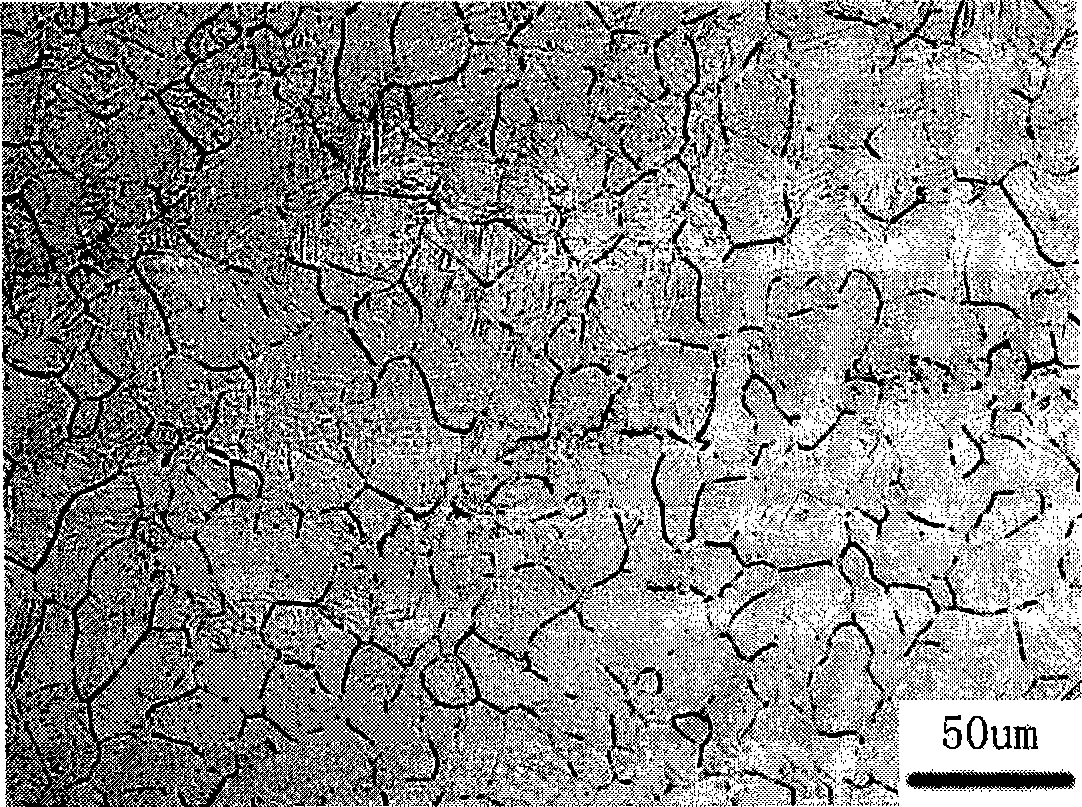

A technology for austenite grains and ship plate steel, which is applied in the field of metallographic sample preparation, can solve the problems of difficult display of austenite grains of high-strength ship plates, and achieves simple and convenient implementation, clear display, and inhibition of matrix structure. and grain boundaries show good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The technological process and steps of the present embodiment are as follows:

[0026] a Heat treatment: heat the sample at 1000°C, keep it warm for 30 minutes, and perform water quenching.

[0027] b Coarse grinding: Grind the sample after quenching on the grinding wheel to remove the surface oxide layer. Grind the polished sample on 0#, 01# coarse sandpaper. Rotate the sample 90° for grinding, and rotate the sample 90° in the same direction when changing the sandpaper, and observe the surface of the sample frequently to ensure that there are no large scratches perpendicular to the grinding direction on the surface.

[0028] c Fine Grinding-Polishing: Grind the coarsely ground sample on fine sandpaper, from 1# sandpaper to 4# sandpaper, the grinding method is the same as that of rough grinding, and make sure that the surface scratches are in the same direction; Wash the sample, and polish it on a polishing cloth. The polishing agent is 1.5 μm diamond polishing paste, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com