A method to reveal the original grain boundary of fe-mn-al-c low density steel

A fe-mn-al-c, low-density steel technology, applied in the field of metallographic detection, can solve the problems of increased difficulty in the original austenite grain size, easy occurrence of mixed crystals, increased corrosion difficulty, etc., to achieve the required The effect of short time, corrosion inhibition and erosion effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

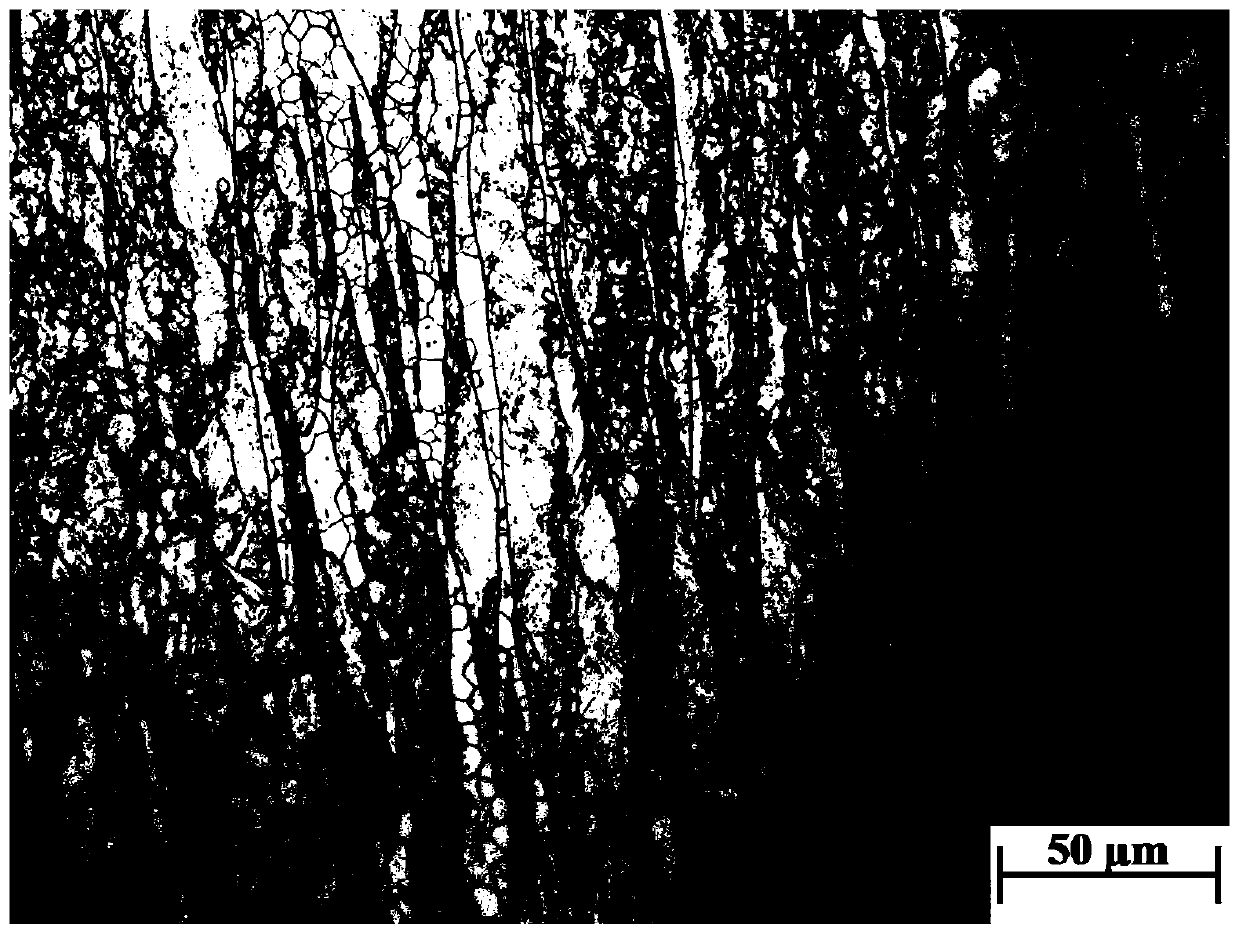

[0033] This embodiment provides a method for displaying the original grain boundaries of Fe-Mn-Al-C low-density steel, such as figure 1 and figure 2 As shown, the method includes: sampling, high temperature deformation, sample preparation, erosion and observation;

[0034] The method operates in the order of sampling-high temperature deformation-sample preparation-erosion-observation;

[0035] The erosion step includes: immersing the metallographic sample obtained in the sample preparation step in an etchant at a temperature T, with the observation surface facing up, and for an erosion time t, when the surface of the observation surface becomes dark, take it out, and put the metallographic sample The surface of the phase sample is wiped clean, and then the metallographic sample is cleaned and dried; the eroded Fe-Mn-Al-C low-density steel corrosion sample is obtained;

[0036] The etching agent formula is: picric acid 1.6g, shampoo 0.26g, hydrochloric acid 0.06ml, anhydrous...

Embodiment 2

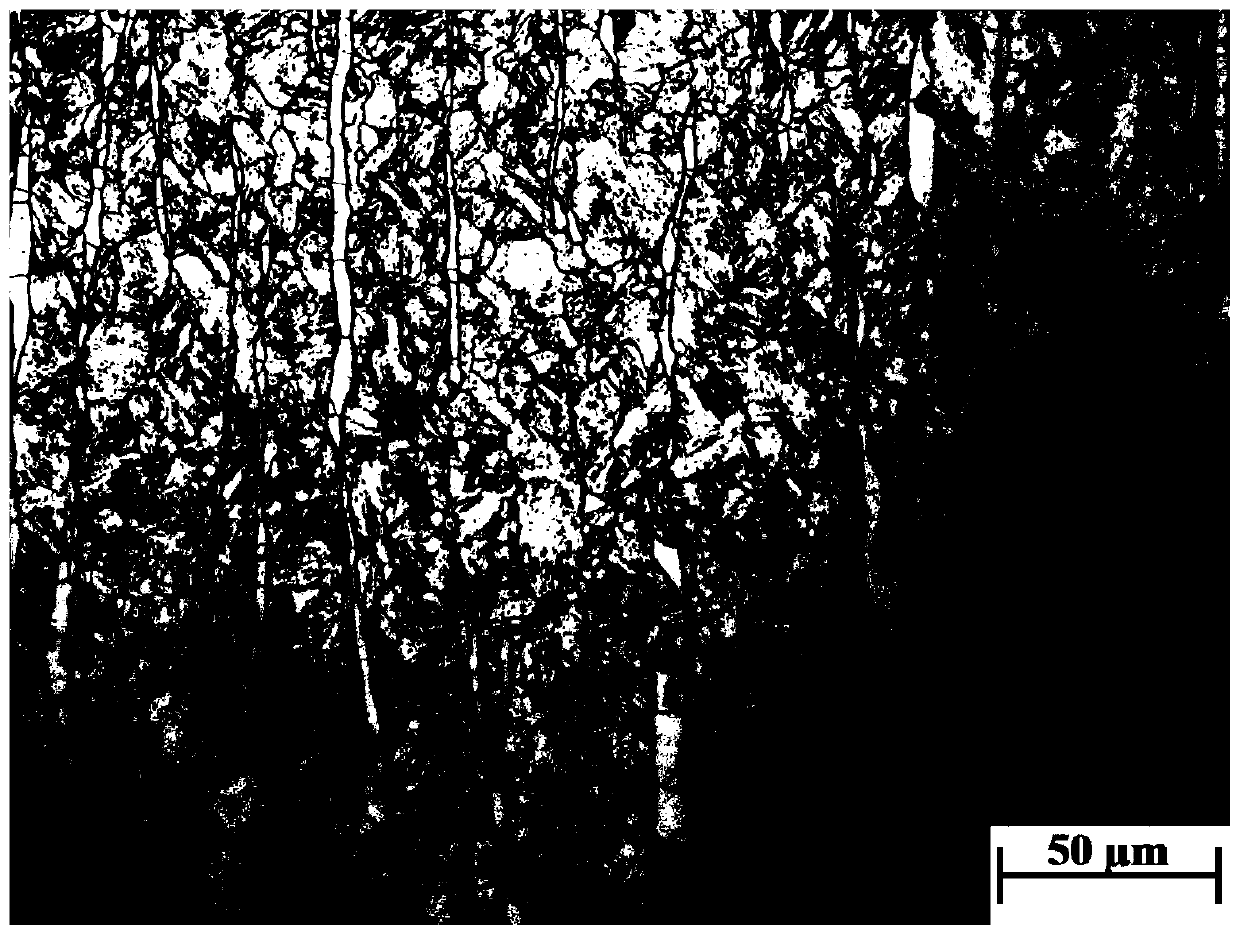

[0051] This embodiment provides a method for displaying the original grain boundaries of Fe-Mn-Al-C low-density steel, such as figure 1 and image 3 As shown, the method includes: sampling, high temperature deformation, sample preparation, erosion and observation;

[0052] The method operates in the order of sampling-high temperature deformation-sample preparation-erosion-observation;

[0053] The erosion step includes: immersing the metallographic sample obtained in the sample preparation step in an etchant at a temperature T, with the observation surface facing up, and for an erosion time t, when the surface of the observation surface becomes dark, take it out, and put the metallographic sample The surface of the phase sample is wiped clean, and then the metallographic sample is cleaned and dried; the eroded Fe-Mn-Al-C low-density steel corrosion sample is obtained;

[0054] The etching agent formula is: picric acid 2.0g, shampoo 0.4g, hydrochloric acid 0.08ml, anhydrous c...

Embodiment 3

[0069] This embodiment is basically the same as Embodiment 1, except that:

[0070] In the high-temperature deformation step, the initial sample is cooled to a deformation temperature of 900°C, and the strain rate is 0.1s -1 compressing said initial sample;

[0071] The erosion temperature T in the erosion step is 68°C, and the erosion time t is 50s;

[0072] The etching agent formula is: picric acid 1.5g, shampoo 0.2g, hydrochloric acid 0.05ml, anhydrous copper sulfate 0.5g, deionized water 200ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com