Large-size corrosion resisting neodymium iron boron permanent magnetic material and manufacturing process thereof

A technology of permanent magnet material and manufacturing method, applied in the direction of magnetic material, inorganic material magnetism, magnetic object, etc., can solve the problems of small size, poor corrosion resistance of NdFeB permanent magnet material, etc. Corrosion improvement and effect of increasing critical temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

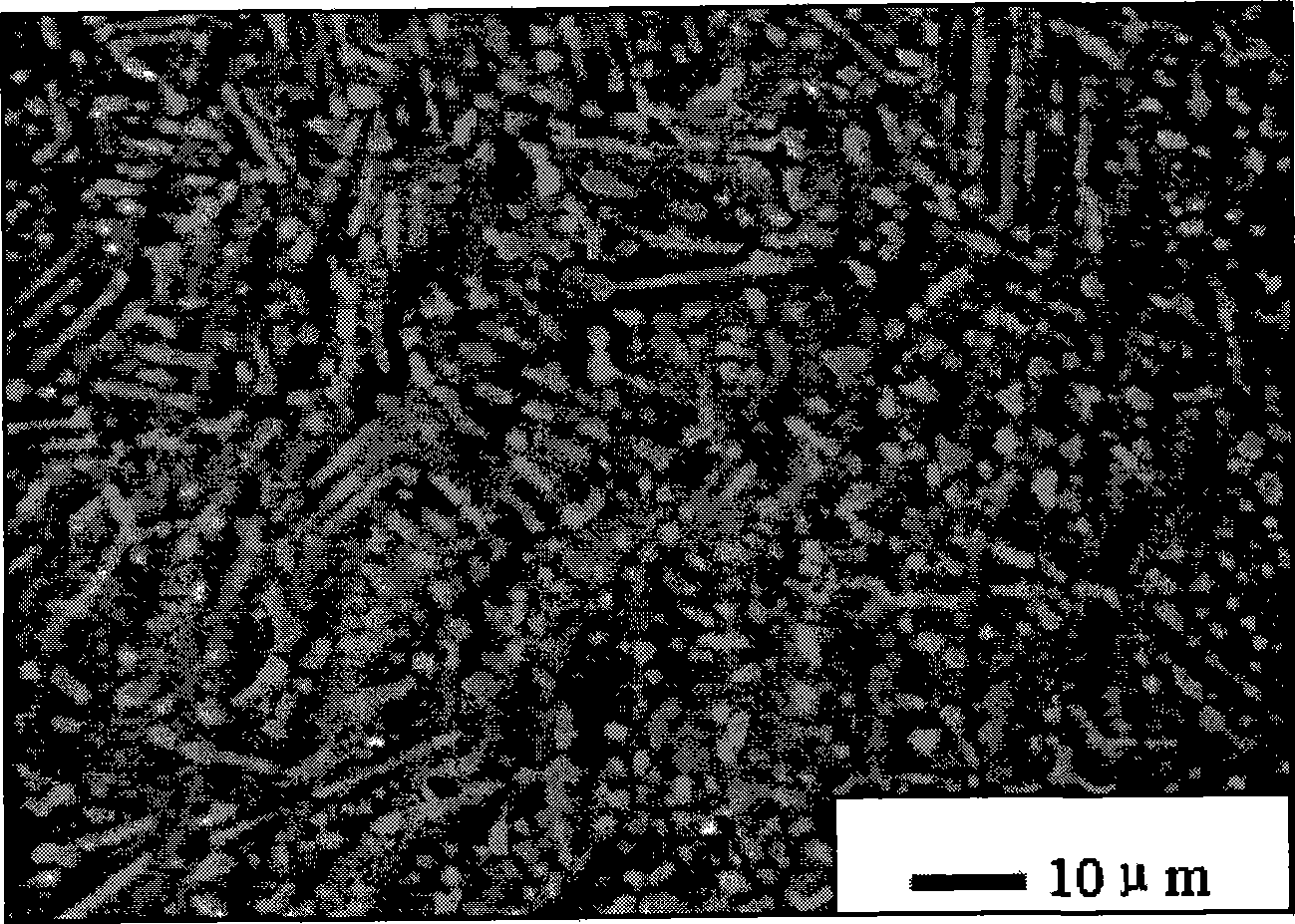

Image

Examples

Embodiment 1

[0038] Example 1: The metal elements are mixed according to the following weight ratios, and prepared into flakes using the quick-setting thin strip process: Nd: 20%, Dy: 6%, Tb: 3%, Pr: 4%, Fe: 55%, Co : 10%, B: 1.1%, Cu: 0.5%, Al: 0.4%, the alloy is crushed by hydrogen gas, crushed by jet mill to make X50=6μm; X90 / X10=5 powder, and formed under the vertical magnetic field press, wherein The orientation field is 15KOe, the pole head of the vertical field press is 200mm, and then isostatic pressing is carried out, and the isostatic pressing pressure is 250MPa; then sintering is carried out at 1060°C for 3 hours, and heat treatment is carried out after sintering. The primary temperature is 850°C, the time is 2.5 hours, the secondary temperature is 500°C, the time is 2.5 hours. The properties of the magnet are:

[0039] Magnetic property: Remanence Br=1.151T

[0040] Intrinsic coercive force Hcj=2278KA / m

[0041] Magnetic energy product BHm=261KJ / m 3 ,

[00...

Embodiment 2

[0046] Example 2: The metal elements are mixed according to the following proportions, and thin sheets are prepared by the quick-setting thin strip process: Nd: 18%, Dy: 10%, Pr: 3%, Fe: 61.4%, Co: 6%, B: 1 %, Cu: 0.15%, Al: 0.3%, Ga: 0.15%, crush the alloy with hydrogen gas, and use jet mill to make X50=4.0μm powder, X90 / X10=4.5, and shape it under vertical magnetic field press, where The orientation field is 20KOe, the pole head of the vertical field press is 300mm, then isostatic pressing is carried out, and the isostatic pressing pressure is 300MPa; then sintering is carried out at 1070°C for 4 hours, and heat treatment is carried out after sintering. The temperature is 900°C for 3 hours, and the secondary temperature is 580°C for 3 hours. The properties of the magnet are:

[0047] Magnetic properties: Remanence Br=1.179T

[0048] Intrinsic coercivity Hcj=2266KA / m

[0049] Magnetic energy product BHm=268KJ / m 3 ,

[0050] Blank size: 127mm×53mm×42mm,

...

Embodiment 3

[0053] Example 3: The metal elements are mixed according to the following proportions, and each thin sheet is made by using the quick-setting thin strip process: Nd: 24%, Tb: 5%, Fe: 67.00%, Co: 2%, B: 0.9%, Cu: 0.1%, Ga: 1%, the alloy is crushed by hydrogen gas, and the powder of 4.5 μm is made by jet milling, X90 / X10=4, and it is formed under a parallel magnetic field press, where the orientation field is 15KOe, and the coil diameter of the parallel field press 250mm, then isostatic pressing, the isostatic pressing pressure is 200MPa; then sintering, the sintering temperature is 1100°C, the time is 2 hours, heat treatment is carried out after sintering, the primary temperature is 850°C, the time is 2 hours, the secondary temperature 600°C for 2 hours. The properties of the magnet are:

[0054] Magnetic properties: Remanence Br=1.210T

[0055] Intrinsic coercive force Hcj=2046KA / m

[0056] Magnetic energy product BHm=282KJ / m 3 ,

[0057] Blank size: 105mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic coercive force | aaaaa | aaaaa |

| Magnetic energy product | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com