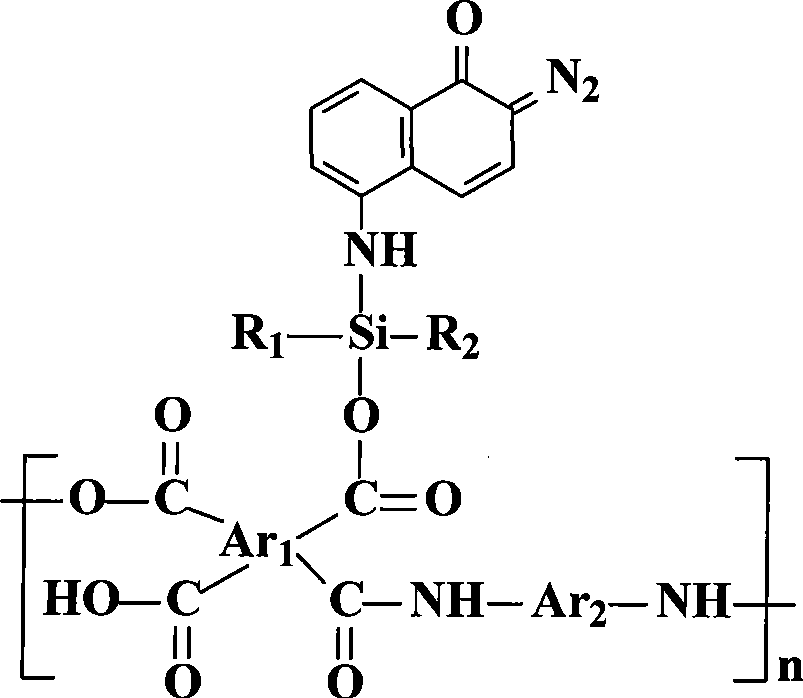

Positive photosensitive polyimide containing silazane chain structure and preparation method thereof

A technology of photosensitive polyimide and chain structure, which is applied in the direction of photomechanical equipment, photographic process of patterned surface, optics, etc., can solve the problems of easy foaming of the coating film, poor film-forming property, and small adhesion, and achieve Strong adhesion, good film-forming property, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

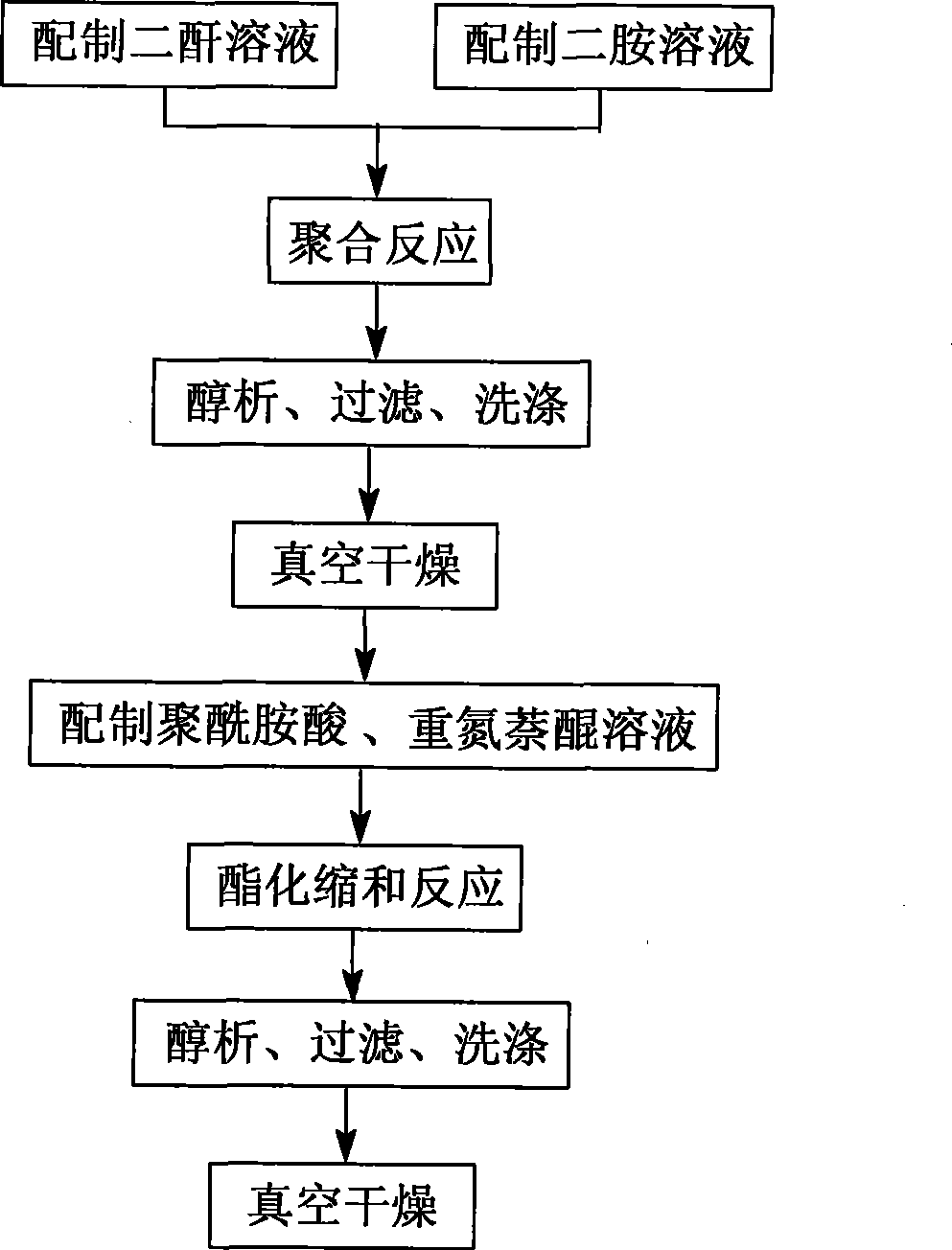

Method used

Image

Examples

specific Embodiment approach 1

[0034] With stirrer and N 2 Add 8.7g of pyromellitic dianhydride and 23ml of N-methylpyrrolidone into the 100ml three-necked flask of the protective device, and stir to dissolve. Add 10ml of N-methylpyrrolidone and 8.0g of 4,4-diaminodiphenyl ether in sequence into a 50ml dropping funnel, shake well until completely dissolved, then add dropwise to pyromellitic acid at a rate of 1-2 drops / second In the dianhydride solution, the reaction was stirred for 6 hours after the dropwise addition was completed. Under vigorous stirring, the reaction solution was poured into 100ml of absolute ethanol, and the solid precipitated after standing still. The obtained solid was filtered, and the filter cake was rinsed with absolute ethanol for 3 times, and then vacuum-dried to obtain 13.2 g of pale yellow solid polyamic acid.

[0035] With stirrer and N 2 Add 4.2 g of polyamic acid, 3.0 g of chlorosilylamino-o-diazonaphthoquinone and 40 ml of N-methylpyrrolidone into a 100 ml brown three-neck...

specific Embodiment approach 2

[0036] With stirrer and N 2 Add 4.4g of pyromellitic dianhydride and 20ml of N,N-dimethylformamide into the 100ml three-necked flask of the protective device, and stir to dissolve. Add 10ml of N,N-dimethylformamide and 4.0g of 4,4'-diaminodiphenylmethane in sequence to a 50ml dropping funnel, shake well until completely dissolved, then add dropwise at a rate of 1-2 drops / second to the homogeneous In the pyromellitic dianhydride solution, stir and react for 4 hours after the dropwise addition is completed. Under vigorous stirring, the reaction solution was poured into 100ml of absolute ethanol, and the solid was precipitated after standing. The obtained solid was filtered, and the filter cake was rinsed with absolute ethanol for 3 times, and then vacuum-dried to obtain 6.1 g of light yellow solid polyamic acid.

[0037] With stirrer and N 2 Add 4.0 g of polyamic acid, 2.8 g of chlorosilylamino-o-diazonaphthoquinone and 40 ml of N-methylpyrrolidone into a 100 ml brown three-ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com