Hollow porous micro-capsule and preparation method thereof

A technology of capsule preparation and microcapsule, applied in microcapsule preparation, microsphere preparation and other directions, can solve the problems of loss of advantages of nanomaterials, loss of dispersibility and mobility of nanoparticles, and achieve the effect of resisting mechanical shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

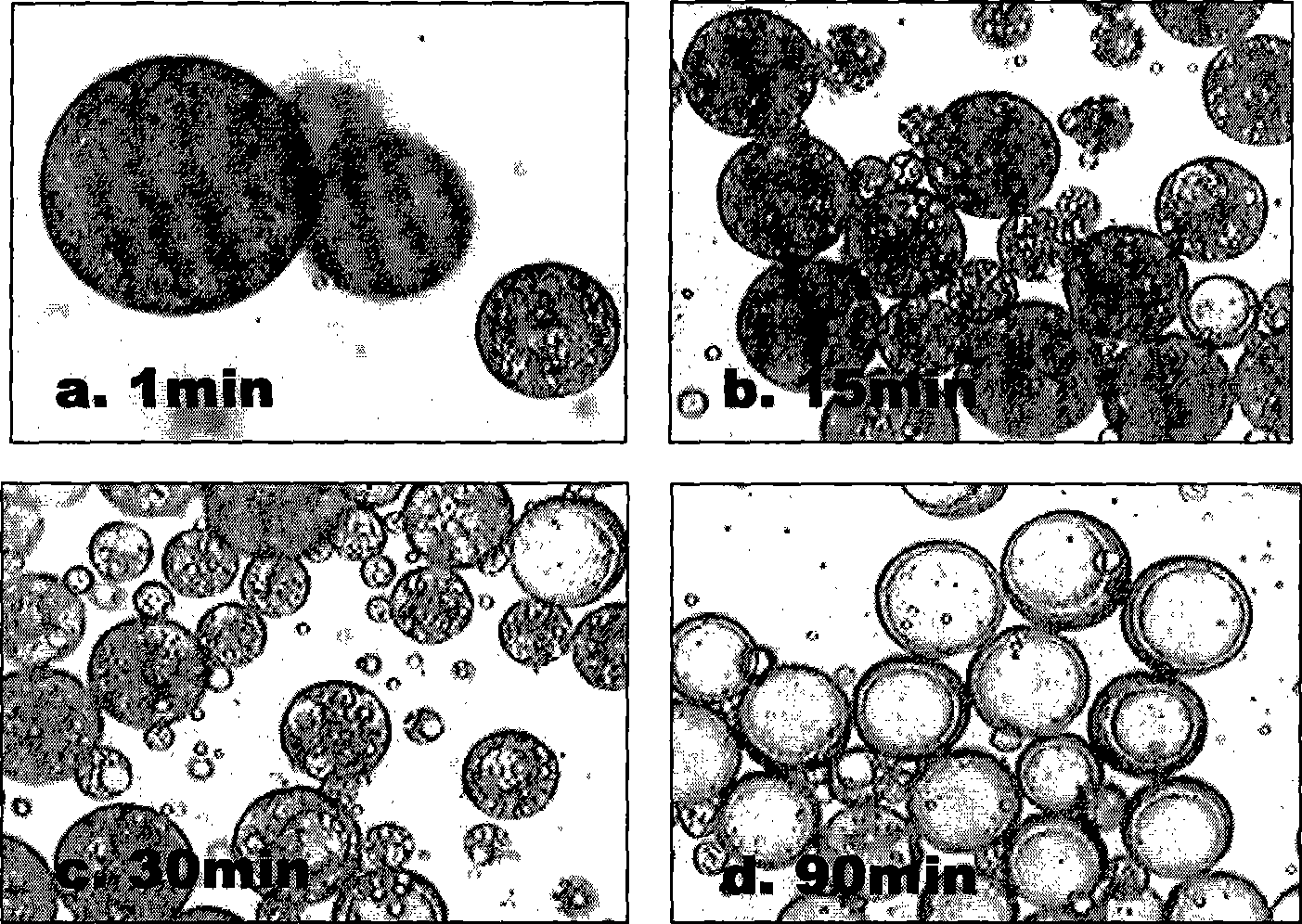

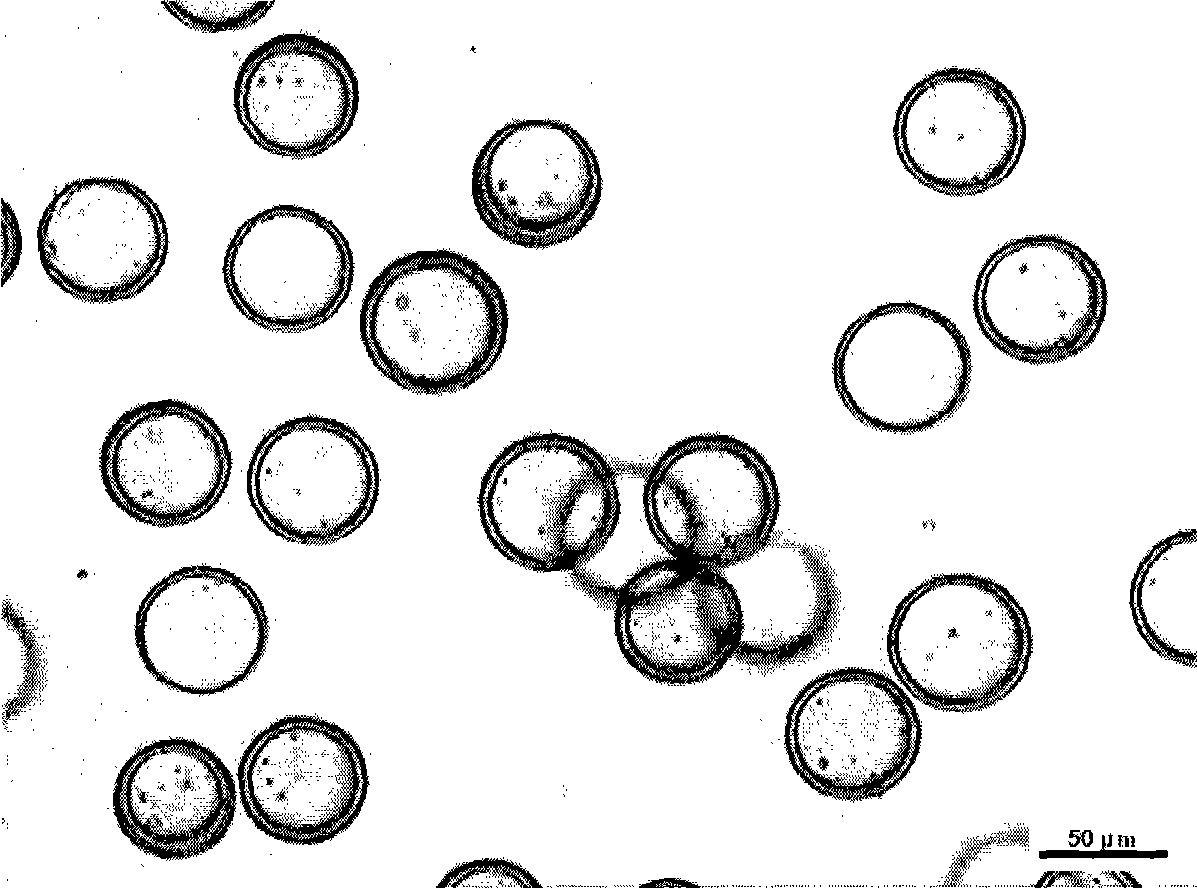

[0030] Embodiment 1: preparation of single cavity capsule

[0031] Table 1 Formula for preparing hollow compound milk capsules

[0032]

[0033] Configure oil phase O and internal water phase W according to the formula in Table 1 1 and external aqueous phase W 2 . First put W 1 Mix with O, ultrasonically break and emulsify for 20 seconds in an ice-water bath, the ultrasonic intensity is 200V, and the interval of each ultrasonic 1 second is 5 seconds. After phacoemulsification, water-in-oil (W 1 / O) primary emulsion, then the primary emulsion is mixed with the external water phase, and mechanical stirring is used to prepare the double emulsion (W 1 / O / W 2 ), the stirring speed is 400rpm, and the emulsification time is 2min. After the double emulsion was prepared, put it into the reactor, under normal pressure and nitrogen protection, adjust the stirring speed to 100rpm, and stir at room temperature for 2 hours; during this process, the double emulsion droplets will gr...

Embodiment 2

[0034] Embodiment 2: Capsule loaded TiO2 nanometer catalyst

[0035] Table 2 Formula for preparing entrapped TiO2 nanopowder capsules

[0036]

[0037] Configure oil phase O and internal water phase W according to the formula in Table 2 1 and external aqueous phase W 2 . Taking Degussa Nano TiO 2 The powder P250 is the loading target. First, the target powder is dispersed into the inner aqueous phase solution by ultrasonic crushing, W 1 The solid content is controlled at 3%. Will W 1 Mix with O, ultrasonically emulsify in an ice-water bath for 60 seconds, and ultrasonic power 200V. Then the primary emulsion is mixed with the external water phase, and the double emulsion is prepared using mechanical stirring (W I / O / W 2 ). After the double emulsion is prepared, put it into the reactor, protect it with nitrogen under normal pressure, control the stirring speed at 100 rpm, and stir at room temperature for 2 hours; the double emulsion droplet will gradually evolve into...

Embodiment 3

[0038] Example 3: Capsules loaded with superparamagnetic particles

[0039] Table 3 Formula for preparing capsules embedded with magnetic particles

[0040]

[0041] Use superparamagnetic particles as the embedding target, and the surface of the target particle is SiO 2 The material contains superparamagnetic nano-cores, and the average size of the particles is 1-2 μm. Configure oil phase O and internal water phase W according to the formula in Table 3 1 and external aqueous phase W 2 . Will W 1 Mix with O, ultrasonically emulsify in ice-water bath for 60 seconds, ultrasonic power 200V. After phacoemulsification, water-in-oil (W 1 / O) primary emulsion, then the primary emulsion is mixed with the external water phase, and mechanical stirring is used to prepare the double emulsion (W 1 / O / W 2 ), the stirring speed is 400rpm, and the emulsification time is 2min. After the double emulsion was prepared, put it into the reactor, under normal pressure and nitrogen protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Lumen diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com