Heat conductive flame-retarding polybutylene terephthalate and preparation method thereof

A polybutylene terephthalate and flame retardant technology, which is applied in the field of polybutylene terephthalate and its preparation, can solve the problem that polybutylene terephthalate flame retardant materials do not have the Thermal conductivity, thermal conductivity of polybutylene terephthalate resin has not been improved, no thermal conductivity, etc., to achieve the effects of good mechanical properties, low viscosity of the system, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

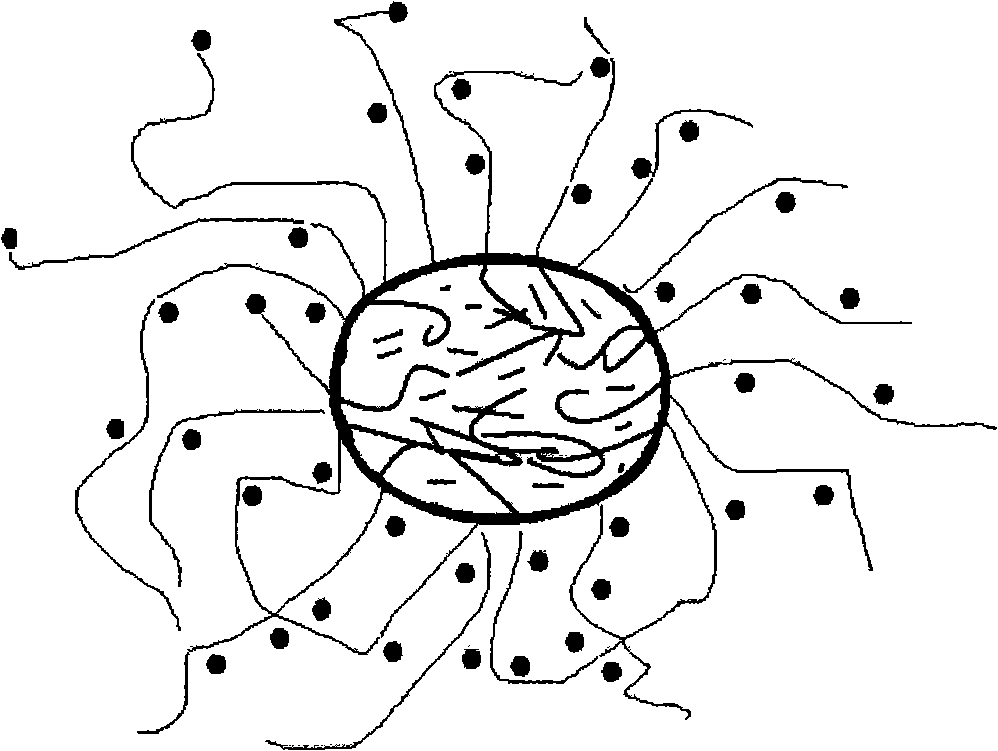

Image

Examples

Embodiment 1

[0024] After fully drying the raw materials, in parts by weight, mix 40 parts of resorcinol-bis(diphenyl phosphate) and 20 parts of polyethylene glycol 6000 monostearate at 5000 rpm to 6000 rpm Perform shearing and stirring for 10 minutes at a rotational speed of rpm, then add 40 parts of magnesium oxide with a particle size of 50nm to 200nm and stir evenly to prepare a thermally conductive flame retardant. Take by weighing 817 grams of polybutylene terephthalate, 150 grams of the above-mentioned thermally conductive flame retardant, 30 grams of compatibilizer ethylene-methyl acrylate-glycidyl methacrylate copolymer (fully dry), 3 grams of Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite in a molar ratio of 1:2 Antioxidant, mix the above components evenly, then extrude, draw, pelletize the obtained mixture in an extruder at 260°C, and inject into samples to make samples. Compatibilizer ethylene-methy...

Embodiment 2

[0029]After fully drying the raw materials, in parts by weight, mix 50 parts of resorcinol-bis(diphenyl phosphate) and 10 parts of polyethylene glycol 6000 monostearate at 5000 rpm to 6000 Perform shearing and stirring for 5 minutes at a rotating speed of rpm, and then add 40 parts of magnesium oxide with a particle size of 50nm to 200nm and stir evenly to prepare a thermally conductive flame retardant. In parts by weight, weigh 781 grams of polybutylene terephthalate, 175 grams of the above-mentioned thermally conductive flame retardant, 40 grams of compatibilizer ethylene-methyl acrylate-glycidyl methacrylate copolymer, 4 grams Composed of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite in a molar ratio of 1:2 Mix the above components evenly, and then extrude, draw, pelletize the resulting mixture in an extruder at 240°C, and inject into samples to perform performance tests. The compatibilizer ethylen...

Embodiment 3

[0031] After fully drying the raw materials, in parts by weight, mix 45 parts of resorcinol-bis(diphenyl phosphate) and 15 parts of polyethylene glycol 6000 monostearate at 5000 rpm to 6000 Perform shearing and stirring for 8 minutes at a rotating speed of rpm, and then add 40 parts of magnesium oxide with a particle size of 50nm to 200nm and stir evenly to prepare a thermally conductive flame retardant. In parts by weight, weigh 745 grams of polybutylene terephthalate, 200 grams of the above-mentioned thermally conductive flame retardant, 50 grams of compatibilizer ethylene-methyl acrylate-glycidyl methacrylate copolymer, 5 grams Composed of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite in a molar ratio of 1:2 Mix the above components evenly, and then extrude, draw, pelletize the resulting mixture in an extruder at 250°C, and inject into samples to perform performance tests. The compatibilizer ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com