Method for synthesizing atosiban acetate from solid phase polypeptide

A solid-phase peptide synthesis, atosi-like technology, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of complex operation, high labor cost, and three wastes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0160] Peptide chain preparation:

[0161] Weigh the amount of Rink Amide AM resin equivalent to 720mmol (200 mesh, 0.80mmol / g), put it into the SHYM-25 peptide synthesizer, soak it in 6000ml DMF to swell the resin, and drain it. Add 6400 ml of a DMF solution with a volume concentration of 25% hexahydropyridine, and shake at 25° C. for 30 minutes. Drain, wash several times with DMF, respectively, and drain.

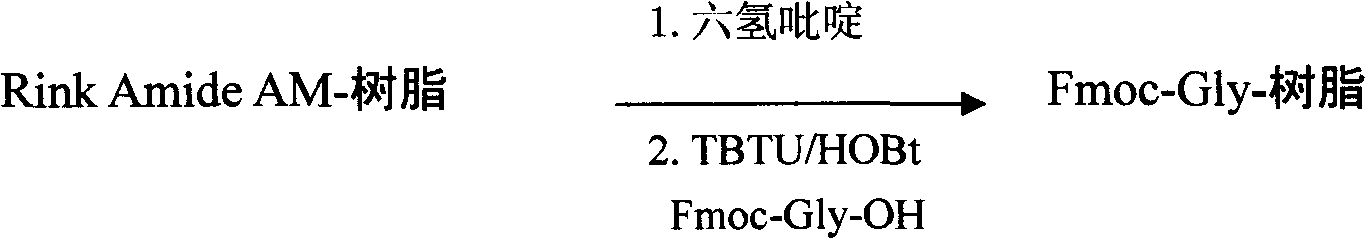

[0162] Preparation of Fmoc-Gly-resin:

[0163] Add Fmoc-Gly-OH (MW: 297.3, 1440mmol) 428g, HOBT (MW: 135.1, 1440mmol) 195g, TBTU (MW: 321, 1440mmol) 462g, NMM 320ml (MW = 101.2), 4000ml DMF, shake the mixture at 25°C Shake for 1.5 hours. Drain, wash with DMF several times, and drain.

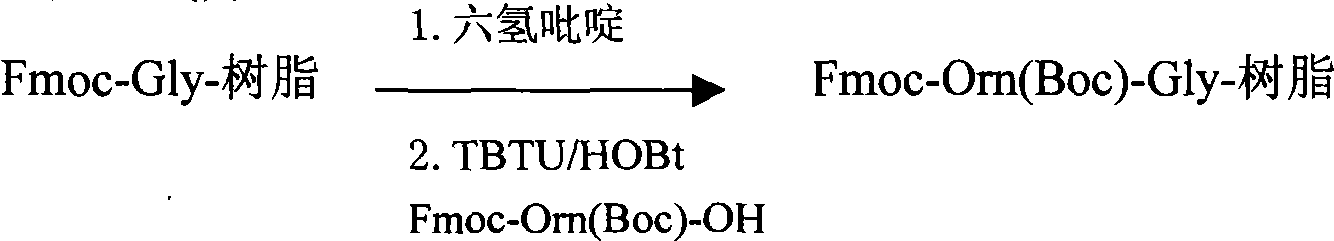

[0164] Preparation of Fmoc-Orn(Boc)-Gly-resin:

[0165] Add 6400 ml of a DMF solution with a volume concentration of 25% hexahydropyridine, and shake at 25° C. for 30 minutes. Drain, wash several times with DMF, and drain.

[0166] Fmoc-Orn (Boc)-OH (MW: 454.5, 1440mmol) 654g, TBTU (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com