Process for preparing n-butyl isocyanate

A technology of n-butyl isocyanate and butyl isocyanate, which is applied in the field of synthesis of organic compounds, can solve the problems of no industrial value, low product content, low yield, etc., and achieve improved conversion rate, improved conversion rate, and reduced side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

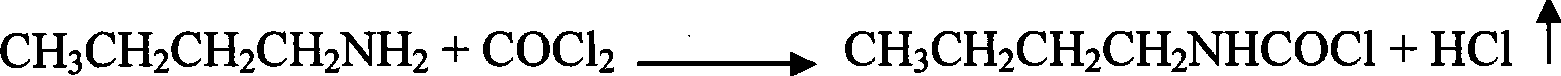

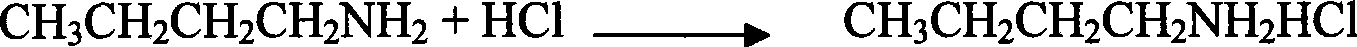

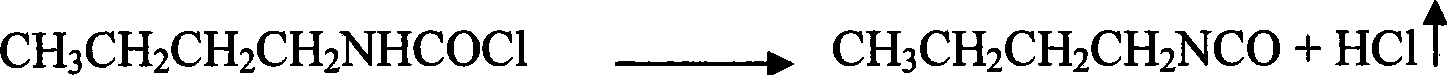

Method used

Image

Examples

Embodiment 1

[0022] Slowly dissolve 10,000 kilograms of n-butylamine in 30,000 kilograms of m-dichlorobenzene to form a solution, and continuously send it to the phosgenation reaction tower from the top of the tower at a flow rate of 500 kilograms / hour through a metering pump; Hours of phosgene is continuously fed into the phosgenation reaction tower from the bottom of the tower; by adjusting the flow rate of coolant or steam in the shell side of the phosgenation reaction tower, the reaction temperature is controlled in 5 stages from the top of the tower to the bottom of the tower to be 0 ° C ~ 5 ° C , 10°C to 20°C, 80°C to 90°C, 110°C to 120°C, 140°C to 150°C; the material flowing out from the bottom of the phosgenation reaction tower is rectified to obtain n-butyl isocyanate with a purity of 99.2%. Based on n-butylamine, the total yield was 96.3%.

Embodiment 2

[0024] Slowly dissolve 10,000 kilograms of n-butylamine in 40,000 kilograms of m-dichlorobenzene to form a solution, and continuously send it to the phosgenation reaction tower from the top of the tower at a flow rate of 500 kilograms / hour through a metering pump; Hours of phosgene is continuously fed into the phosgenation reaction tower from the bottom of the tower; by adjusting the coolant or steam flow rate in the shell side of the phosgenation reaction tower, the reaction temperature is controlled in 5 stages from the top to the bottom of the tower to -5°C~0 ℃, 20℃~30℃, 80℃~90℃, 100℃~110℃, 120℃~130℃; the material flowing out from the bottom of the phosgenation reaction tower is rectified to obtain n-butyl isocyanate with a purity of 99.1%. Based on n-butylamine, the total yield is 96.1%.

Embodiment 3

[0026] Slowly dissolve 10,000 kg of n-butylamine in 50,000 kg of m-dichlorobenzene to form a solution, and continuously send it to the phosgenation reaction tower from the top of the tower at a flow rate of 500 kg / hour through a metering pump; Hours of phosgene is continuously fed into the phosgenation reaction tower from the bottom of the tower; by adjusting the coolant or steam flow rate in the shell side of the phosgenation reaction tower, the reaction temperature is controlled in 5 stages from the top to the bottom of the tower to -5°C~0 ℃, 10℃~20℃, 60℃~80℃, 90℃~110℃, 130℃~140℃; the material flowing out from the bottom of the phosgenation reaction tower is rectified to obtain n-butyl isocyanate with a purity of 94.7%. Based on n-butylamine, the total yield is 83.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com