Permanent magnetism magnetic pole component for high-power permanent magnet motor

A technology for permanent magnet motors and permanent magnet generators, which is applied in the directions of permanent magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. It can solve the problems of magnetic pole assembly difficulty, cumbersome assembly process, and temperature rise, etc., to achieve Simple and stable magnetic pole interlocking fixed structure, improved corrosion resistance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

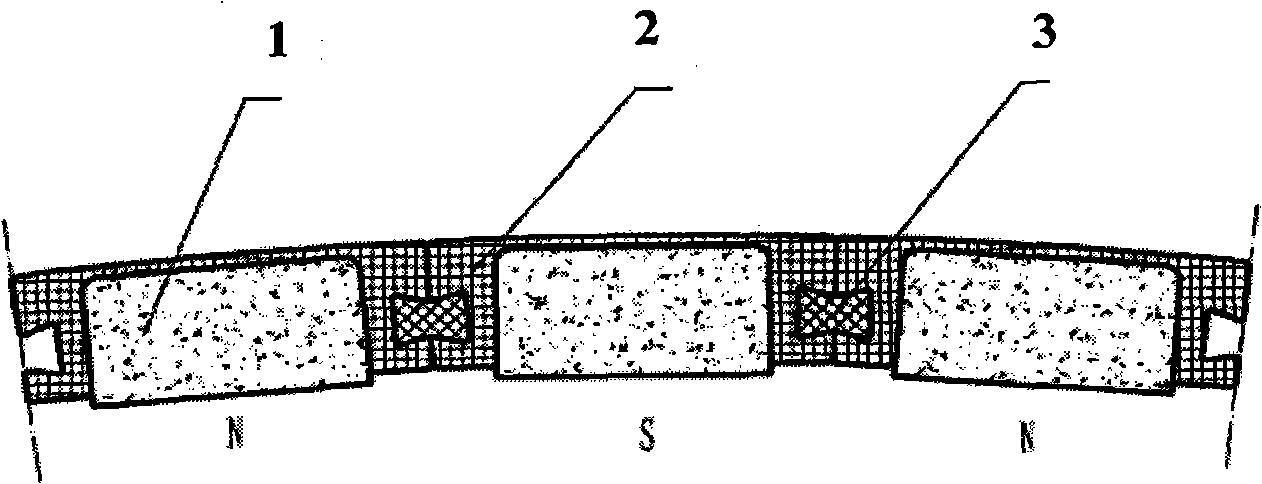

Embodiment 1

[0041] Figure 5 It is a partial view of the stator and rotor of a 2MW direct-drive permanent magnet wind turbine, the inner rotor structure, AC voltage: 690V, speed: 20rpm, multi-pole fractional slot winding, and the magnetic pole form is the same as figure 1 Similarity: the width of permanent magnet 1 is 50mm, and the axial length of permanent magnet 1 is 1200mm. The magnet protection positioning cover 2 is injection-molded as a whole. After magnetization, it is bonded and fixed with the rotor magnet yoke 4 of the motor with epoxy resin adhesive. The radial N and S magnetic poles are alternately arranged on the rotor magnet yoke 4. Splicing of the same polarity, after the adjacent magnetic poles are bonded, the magnetic poles are locked by injection-molded double dovetail-shaped magnetic pole locking pins 3 (with epoxy resin adhesive), and the magnet protection positioning cover 2 and magnetic pole locking pin 3 The material is heat-resistant insulating material-PPS (polyph...

Embodiment 2

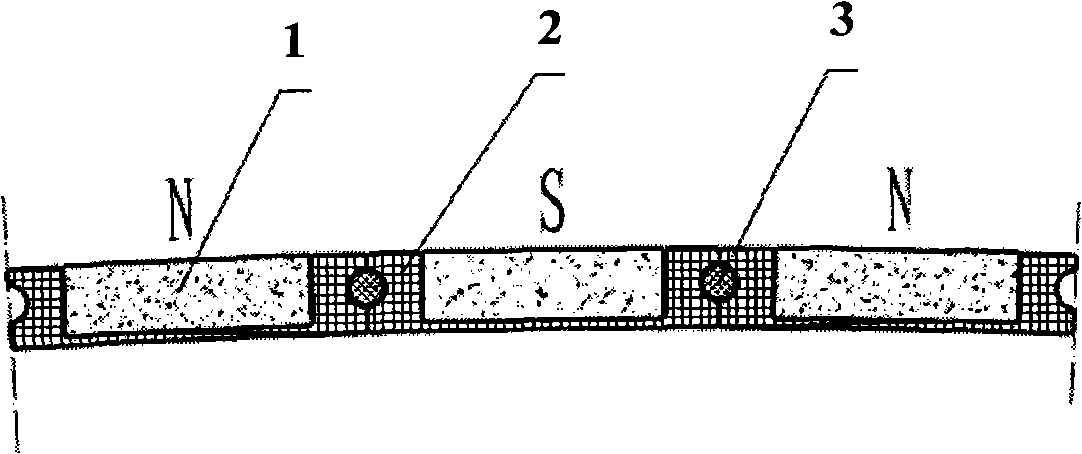

[0043] Figure 6 It is a partial view of the stator and rotor of a 3MW direct-drive permanent magnet wind turbine, the outer rotor structure, AC voltage: 690V, speed: 19rpm, multi-pole fractional slot winding, and the magnetic pole form is the same as figure 2 Similar, the width of permanent magnet 1 is 65mm, and the axial length of permanent magnet 1 is 1000mm. The injection-molded magnet protection positioning cover 2 is bonded as a whole with epoxy resin glue, and after magnetization, the epoxy resin adhesive is used to bond and fix the motor rotor magnet yoke 4, and the radial N and S magnetic poles are alternately arranged on the rotor On the magnet guide yoke 4, the axial direction is spliced with the same polarity. After the adjacent magnetic poles are bonded, the magnetic poles are locked by injection-molded circular magnetic pole locking pins 3 (add epoxy resin adhesive) and the positioning cover is protected by the magnet. 2 and the magnetic pole locking pin 3 ar...

Embodiment 3

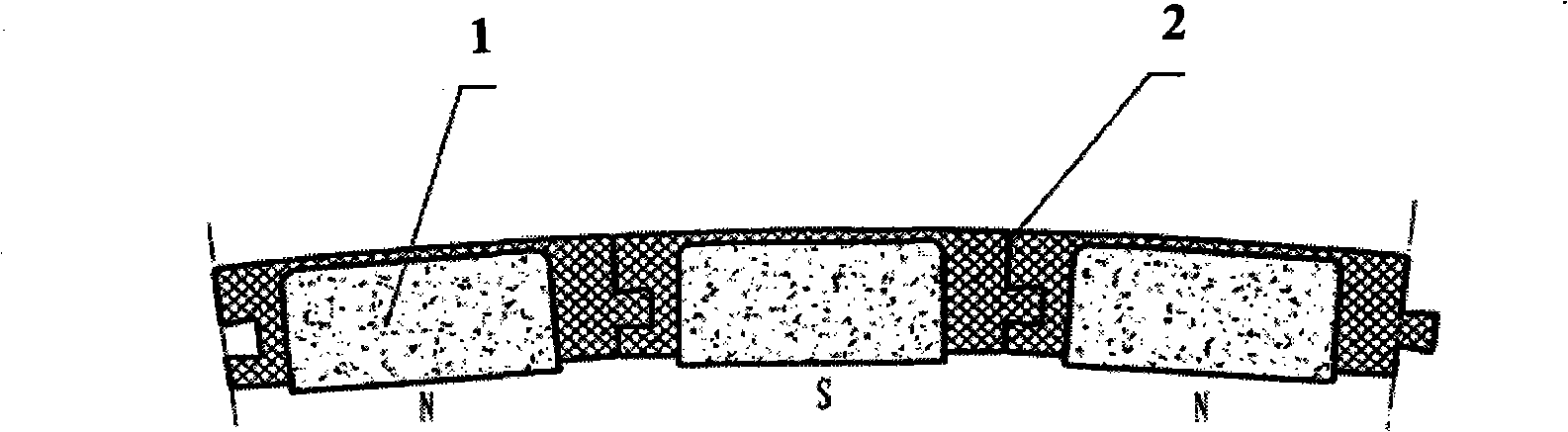

[0045] Figure 7 Partial view of the stator and rotor of the permanent magnet linear motor used for sorting and transmission in the post and telecommunications system, driving voltage: 100V, maximum speed: 3m / sec, multi-pole fractional slot winding, magnetic pole form and image 3Similarly, the width of permanent magnet 1 is 30mm, the length of permanent magnet 1 (axial direction) is 100mm, and the stator (when the linear motor is working, the magnetic pole part is still, called the stator), the permanent magnet 1 is composed of a single piece (10×30×98mm) of neodymium iron The boron permanent magnet block is composed of a single NdFeB permanent magnet block and the injection-molded magnet protection positioning cover 2 bonded together with epoxy resin glue, and the epoxy resin adhesive is used to connect the motor stator magnet guide yoke 4 after magnetization Bonding and fixing, the N and S magnetic poles in the length direction of the motor stator are alternately arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com