Method for determining titanium content in copper alloy

A measurement method, copper alloy technology, applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, etc., can solve the problem of decreased accuracy and color development. Insufficient stability of the agent hydrogen peroxide, color interference and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (verify the best assay condition of the assay method of titanium content in the copper alloy of the present invention):

[0033] Pipette 10.00ml of titanium standard solution into a 50ml measuring flask, add 10.00ml of bottom solution, and add water to about 30ml.

[0034] Then add 1ml of ascorbic acid solution, drop a drop of bromophenol blue indicator, adjust to just blue with ammonia water, immediately adjust to yellow with hydrochloric acid and add 1 drop, add 6ml of acetic acid solution, shake well; accurately add 2.00ml of color-changing acid solution , dilute with water to the mark of the measuring bottle, and shake well.

[0035] Pour the color-developing solution into a 1cm cuvette, add 1-2 drops of ammonium fluoride solution to the remaining solution to remove the color of the complex, and use this as the reference solution.

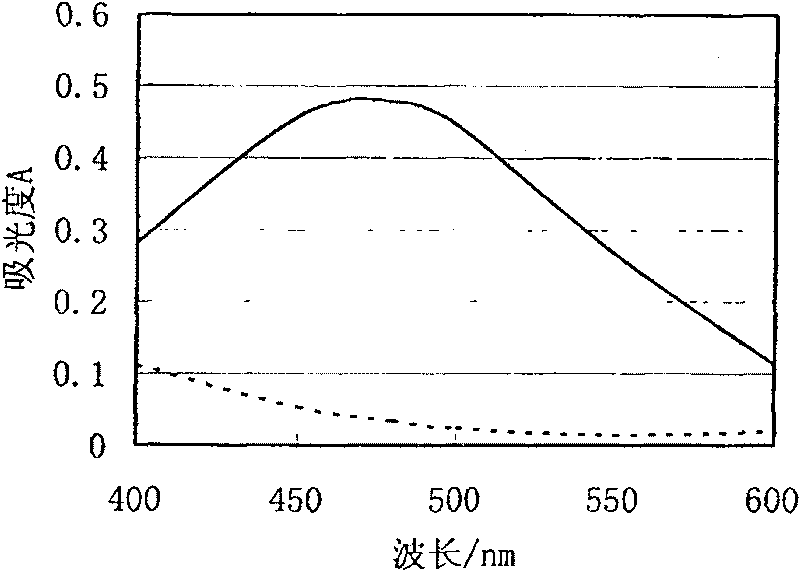

[0036] Use a photometer to read the absorbance of the above-mentioned chromogenic solution and reference solution at diff...

Embodiment 2

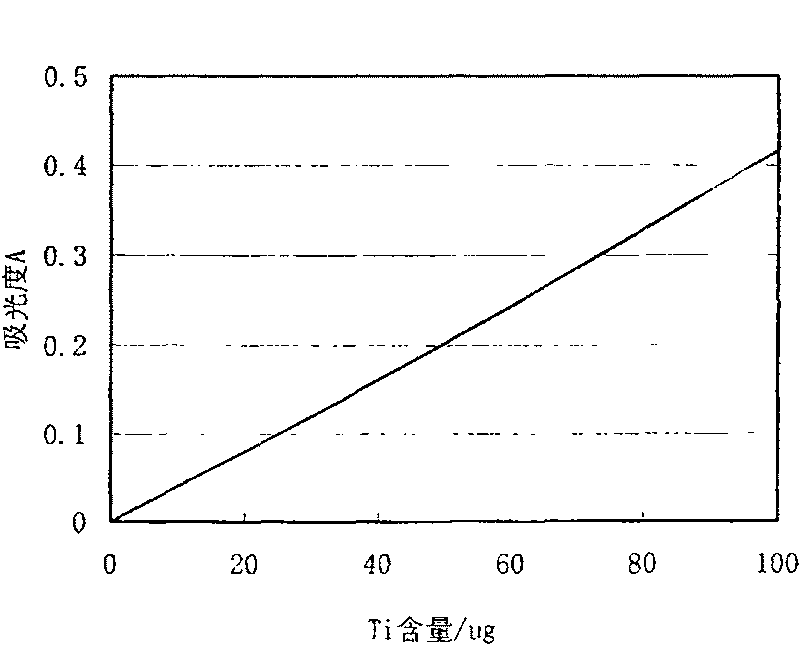

[0039] Embodiment 2 (verify the measurement range of the assay method of titanium content in the copper alloy of the present invention is wide):

[0040] Pipette 0.00ml, 2.00ml, 4.00ml, 6.00ml, 8.00ml, 10.00ml titanium standard solution, place in 6 50ml volumetric flasks, add 10.00ml of bottom solution respectively, operate according to the test procedure of embodiment 1 respectively, read Measure the absorbance and draw the working curve.

[0041] as table 1 and figure 2 As shown, the test results show that under the test conditions, the titanium content obeys Beer's law in the range of 0-100 μg, and it can be concluded that the method for measuring the titanium content in the copper alloy of the present invention has the advantage of a wide range of measurement. However, as shown in Table 2, other measuring methods have relatively narrow measuring ranges.

[0042] Table 1: Ti content / ug~absorption A relationship table

[0043] Ti content / ug

0

20

...

Embodiment 3

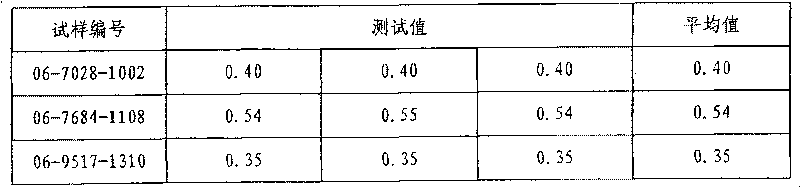

[0046] Embodiment 3 (verify the accuracy of the assay method of titanium content in the copper alloy of the present invention is high)

[0047] Weigh 0.2000 g of the copper alloy standard sample (the standard value of titanium in the copper alloy standard sample is 0.51%) and place it in a 100 ml measuring bottle, add 15 ml of nitric acid, heat to dissolve, add 5 ml of urea solution, cool, and dilute to the scale of the measuring bottle , shake well. Pipette 10.00ml of this solution into a 50ml measuring bottle, add water to about 30ml, then add 1ml of ascorbic acid solution, drop a drop of indicator, adjust to just blue with ammonia water, immediately adjust to yellow with hydrochloric acid and add 1 drop in excess, Add 6ml of acetic acid solution and shake well. Accurately add 2.00ml of color-changing acid solution, dilute with water to the mark of the measuring bottle, and shake well. Pour the chromogenic solution into a 1cm cuvette. Add 1 to 2 drops of ammonium fluoride...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com