Biomass granule material combustor

A biomass particle and burner technology, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve the problems of not easy to popularize and use, complicated burner structure, easy carbon deposition on the rotating core, etc., and achieves environmental protection. The effect is good, the effect of solving the smoke in the material box and the low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

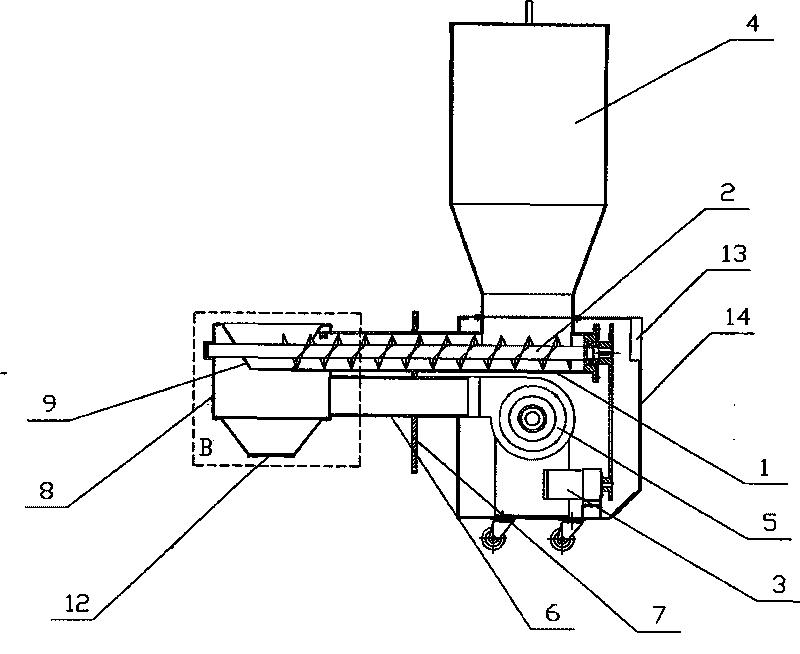

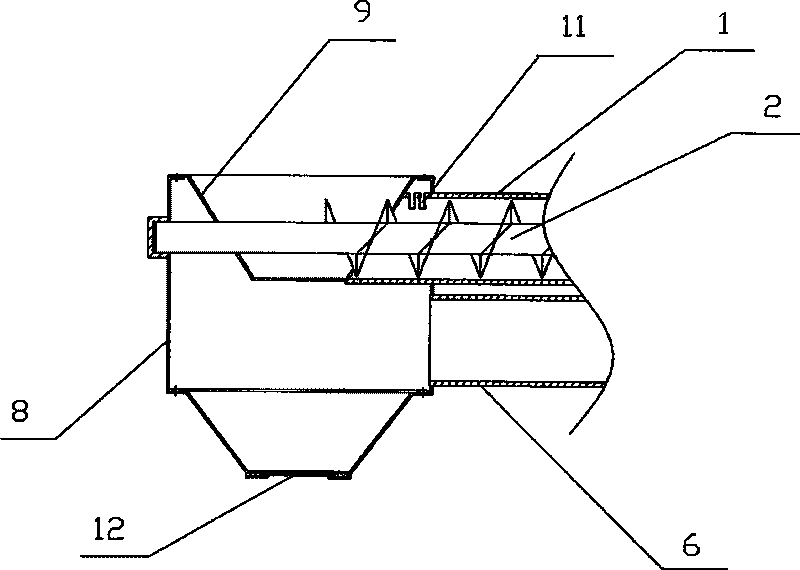

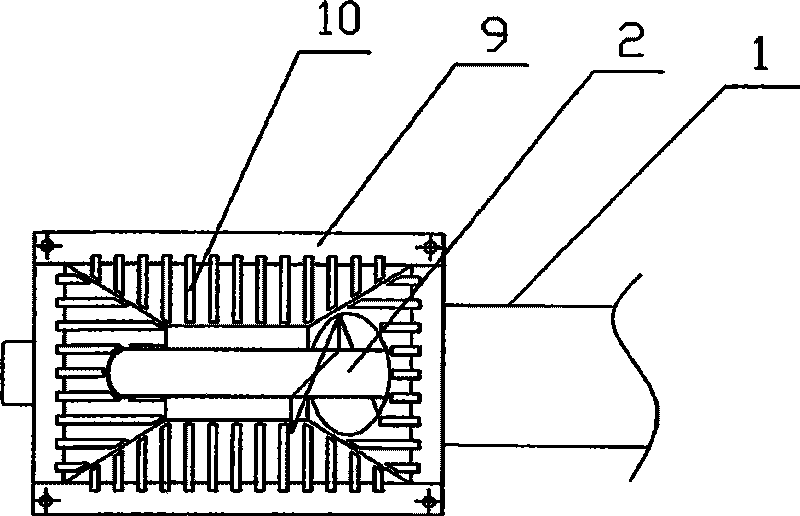

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

[0015] like figure 1 , figure 2 , image 3 In the shown embodiment, a biomass pellet burner includes a feed system, an air supply system, and a combustion system, and the feed system and the air supply system are fixed on the frame 14 . The feeding system includes a material tube 1, a feeding auger 2 installed in the material tube 1, a gear motor 3, and a material box 4. The gear motor 3 drives the feeding auger 2 to rotate and feed in the material tube 1, and the material tube 1 Including a material inlet and a material outlet, the material inlet of the material pipe 1 is arranged at the bottom of the material box 4 and connected through the material box 4 . The air supply system includes a fan 5 and an air supply pipe 6. One end of the air supply pipe 6 is connected to the fan 5, and the other end is an air outlet. The air supply pipe 6 is located below the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com