Method for preparing biodiesel by catalysis of nano magnetic sulphonated coal

A biodiesel and nanomagnetic technology, applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve problems such as separation and equipment corrosion, and achieve high reaction conversion rate, avoid high pressure state, and low temperature catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing biodiesel from nano-magnetic sulfonated coal catalyzed by catalyzing high-acid-value oil and glycerin with an acid value of 20-140 under the catalysis of nano-magnetic sulfonated coal with a relative oil mass percentage of 2-5% , react at 120-180°C for 2-4 hours, cool to 60°C, place the reaction bottle in a magnetic field with a strength of 0.7-0.8T, the magnetic catalyst will quickly gather at the bottom of the bottle within 5-10 minutes, and the upper liquid will be clarified After being transparent, vacuum absorb the upper layer of transparent liquid to obtain liquid oil with an acid value lower than 3; the low acid value oil, methanol pre-dissolved with basic metal oxides, and co-solvent are respectively in a molar ratio of 1:6:0.3 Put it into a static mixer with a preheating temperature of 30-50°C through a piston pump, and after fully mixing, enter into a pipeline reactor at about 60°C, and circulate for about 10 minutes. Diesel oil, crude g...

Embodiment 2

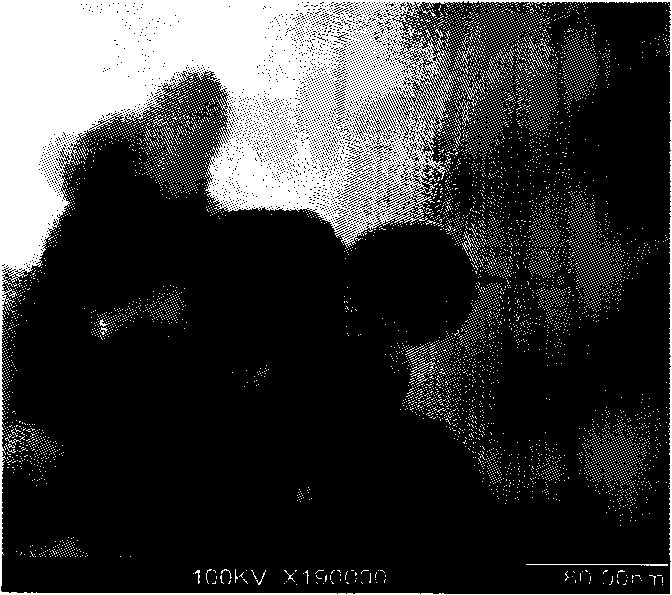

[0027] 100 grams of raw coal, 120 grams of concentrated sulfuric acid with a mass concentration of 98%, reacted for 1 to 2 hours at a temperature of 120 to 150 ° C, filtered, and washed to neutrality, added 50 to 100 grams of distilled water, water milled to slurry, The particle size of the sulfonated coal slurry is controlled at 20-100nm, the solid content is 10%, and stored for later use. 200ml of ferrous sulfate solution with a concentration of 0.02g / ml, within 10 minutes, add 20ml of sodium hydroxide solution with a concentration of 100g / L under stirring, react for 20 minutes, control the particle size of the slurry at 100-1000nm, solidify Content 20%. Add 10 parts by mass of ferrous hydroxide containing 20%wt of ferrous hydroxide with a particle size of 100-1000nm into 100 parts by mass of slurry containing 10%wt of sulfonated coal under constant stirring, heat up at 100°C, and react After 1 hour, spray dry to obtain a 100-1000nm magnetic sulfonated coal catalyst.

[002...

Embodiment 3

[0031]100 grams of raw coal, 120 grams of concentrated sulfuric acid with a mass concentration of 98%, reacted for 1 to 2 hours at a temperature of 120 to 150 ° C, filtered, and washed to neutrality, added 50 to 100 grams of distilled water, water milled to a slurry, and made The particle size of the sulfonated coal slurry is controlled at 20-100nm, the solid content is 10%, and it is stored for future use. 200ml of ferrous sulfate solution with a concentration of 0.02g / ml, within 10 minutes, add 20ml of sodium hydroxide solution with a concentration of 100g / L under stirring, react for 20 minutes, control the particle size of the slurry at 100-1000nm, solidify Content 20%. Add 10 parts by mass of ferrous hydroxide containing 20%wt of ferrous hydroxide with a particle size of 100-1000nm into 100 parts by mass of slurry containing 10%wt of sulfonated coal under constant stirring, heat up at 100°C, and react for 1 Hours, spray-dried to obtain a 100-1000nm magnetic sulfonated coal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com