Flue gas catalytic oxidation denitration technique and catalyst thereof

A catalytic oxidation and catalyst technology, which is applied in the fields of coal combustion, flue gas catalytic oxidation and denitrification process and its catalyst, oil-fired boilers and industrial furnaces, to achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

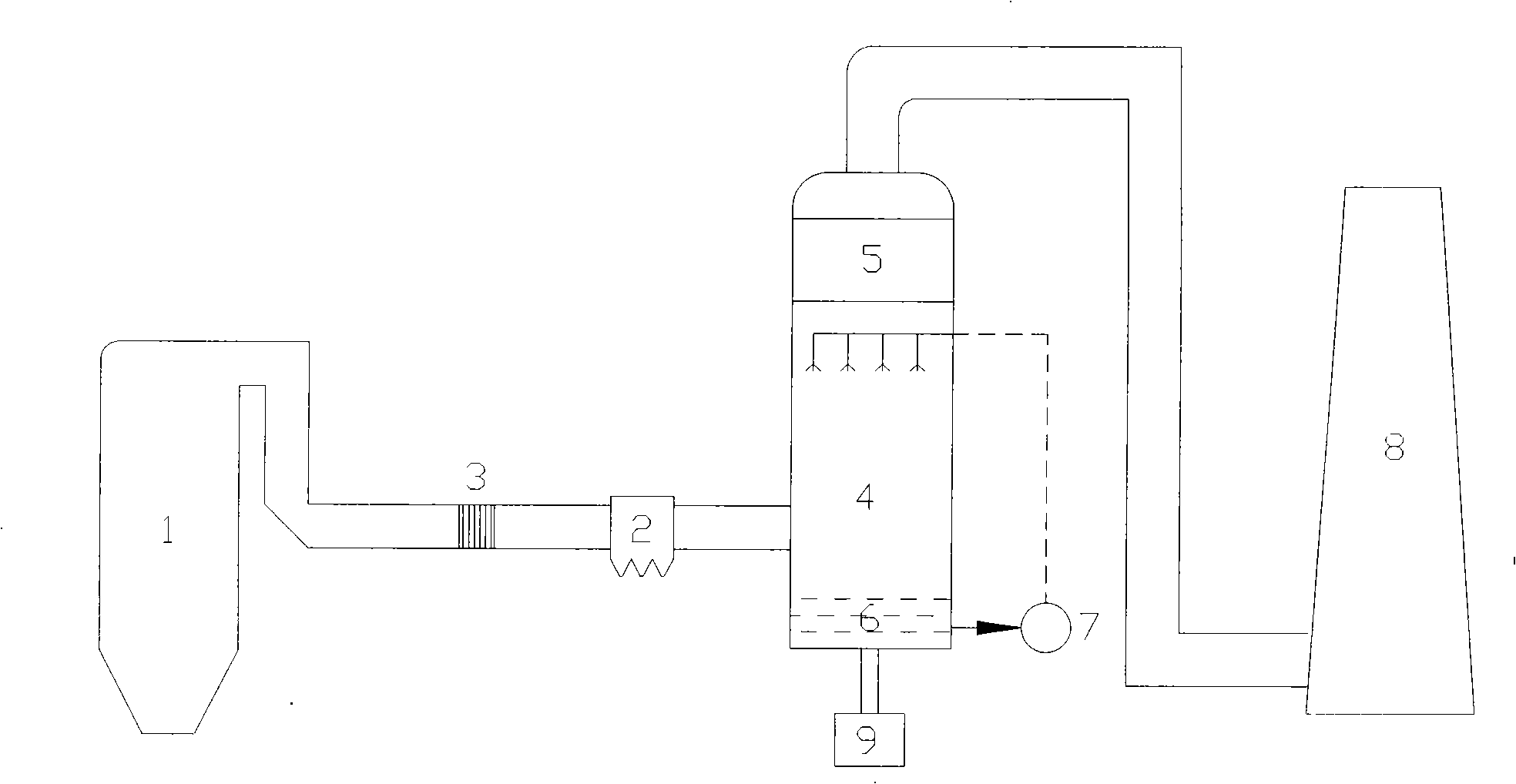

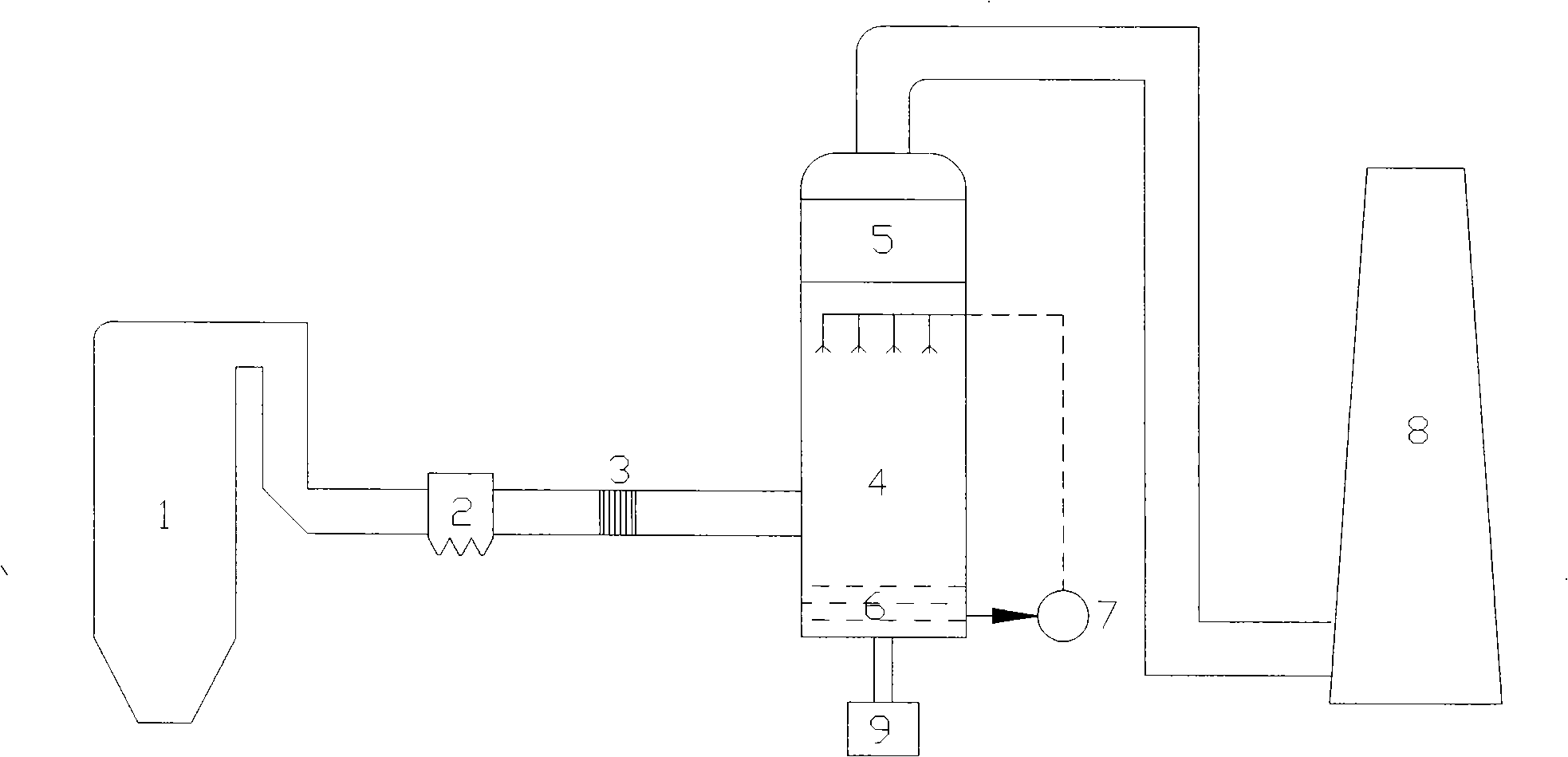

Method used

Image

Examples

Embodiment 1

[0025] 1) Preparation of catalyst CoO by sol-gel method x / TiO 2

[0026] Using n-butyl titanate, ethanol, water, and acetic acid as raw materials, the volume ratio of each component is as follows, n-butyl titanate: ethanol: water: acetic acid = 1: 1.5: 0.5: 0.5, and the amount of cobalt nitrate added is Co : Ti (molar ratio) = 0.1, mixed, after the sol is transformed into a gel, dried, ground, and calcined at 500° C. to obtain a catalyst.

[0027] 2) Denitrification process

[0028] Treat flue gas O 2 Concentration 3%, GHSV (gas space velocity per hour) = 30000h -1 , the catalytic reactor is installed upstream of the dedusting device, the reaction temperature is 300°C, and the reactor outlet is NO 2 / (NO+NO 2 ) ratio of about 40%-60%, the oxidized flue gas enters the spray tower, and the SO 2 with NO x Remove together, the desulfurization efficiency is 90%, and the denitrification efficiency is 75%.

Embodiment 2

[0030] 1) Preparation of catalyst CoO by impregnation method x / TiO 2

[0031] Cobalt nitrate was added to commercial titanium dioxide slurry, stirred for 48 hours, dried at 100°C, calcined at 500°C for 2 hours, and ground to obtain a catalyst. The amount of cobalt added is Co:Ti (molar ratio)=0.05.

[0032] 2) Denitrification process

[0033] Treat flue gas O 2 Concentration 5%, GHSV (gas space velocity per hour) = 50000h -1 , the catalytic reactor is installed upstream of the dedusting device, the reaction temperature is 350°C, and the reactor outlet is NO2 / (NO+NO 2 ) ratio of about 40%-60%, the oxidized flue gas enters the packed tower, and the SO 2 with NO x Remove together, the desulfurization efficiency is 95%, and the denitrification efficiency is 80%.

Embodiment 3

[0035] 1) Preparation of catalyst CoO by sol-gel method x / ZrO 2 -TiO 2

[0036] Using n-butyl titanate, ethanol, water, and acetic acid as raw materials, the volume ratio of each component is as follows, n-butyl titanate: ethanol: water: acetic acid = 1: 1.65: 0.05: 0.07, and the amount of cobalt nitrate added is Co : Ti=0.05, the addition of zirconium nitrate is Zr:Ti (molar ratio)=0.1, mixed, after the sol is converted into gel, dried, ground, and roasted at 600°C to obtain the catalyst.

[0037] 2) Denitrification process

[0038] Treat flue gas O 2 Concentration 8%, GHSV (gas space velocity per hour) = 40000h -1 , the catalytic reactor is installed downstream of the dedusting device, the reaction temperature is 200°C, and the reactor outlet is NO 2 / (NO+NO 2 ) ratio of about 40%-60%, the oxidized flue gas enters the swirl plate tower, and the SO 2 with NO x Remove together, the desulfurization efficiency is 90%, and the denitrification efficiency is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com