High-speed filtering, high-temperature, high-pressure squeezing and drying flexible tube type solid-liquid processing equipment

A liquid treatment, high temperature technology, applied in high pressure pressing and drying flexible tubular solid-liquid treatment devices, high-speed filtration, high temperature fields, can solve the problems of inability to remove the filter residue attached to the filter membrane, complicated mechanism, improved and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

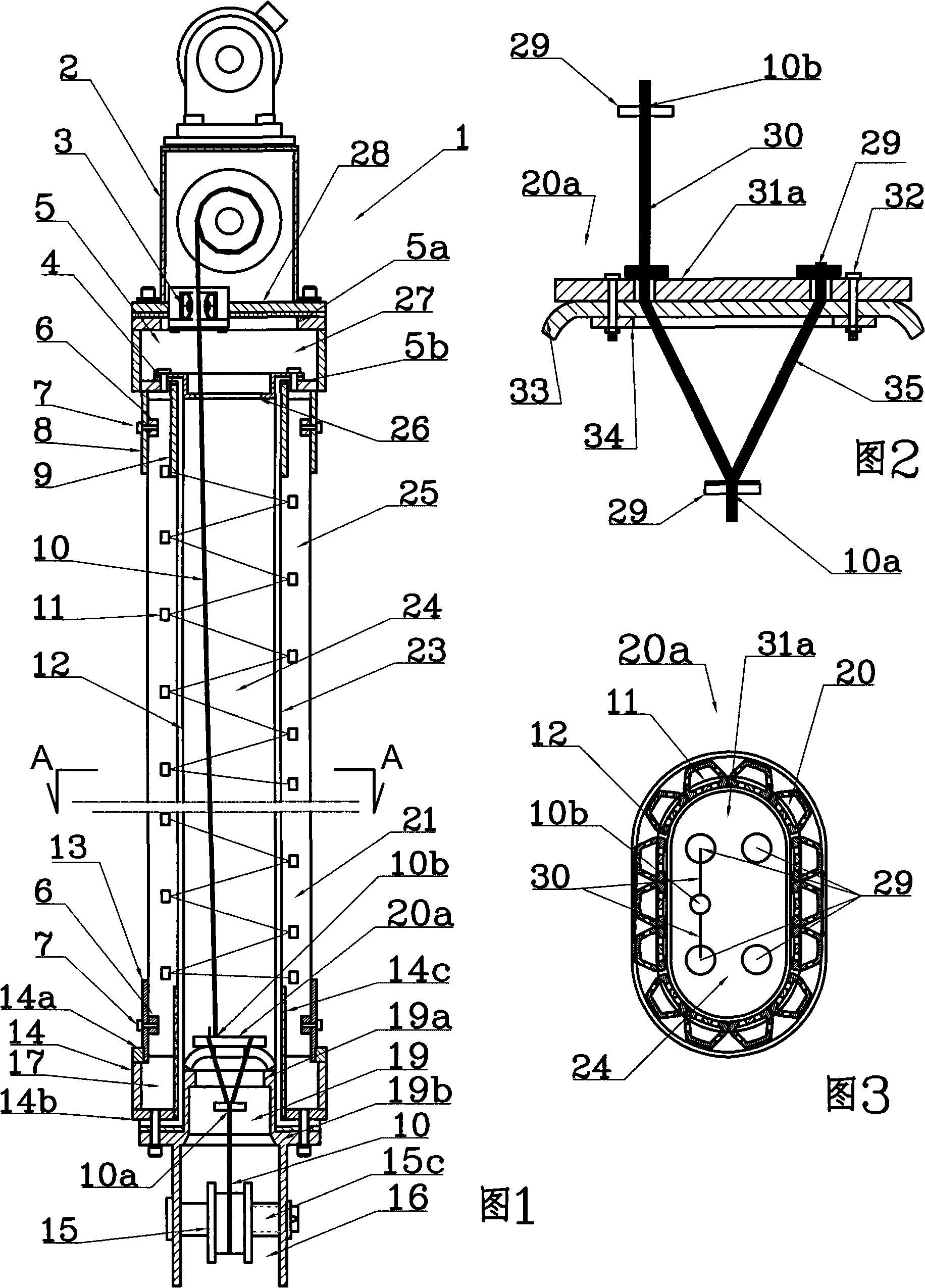

[0056] The described membrane unit 1 of the invention in the present embodiment comprises the following elements of flexibility: a tubular filter membrane 12 and a tubular grid 21, and the long axis centerlines of the tubular filter 12 and the tubular grid 21 coincide and are perpendicular to the horizontal line A circular slurry chamber 24 is formed in the tubular filter membrane 12, and a tubular grid 21 is arranged outside the tubular filter membrane 12; the upper flange chamber 5 is surrounded by a hollow airtight nearly rectangular chamber with plates 5a, 5b, etc. As the stock solution channel 27, the stock solution channel 27 is provided with a feed port G1; the filter slurry chamber 24 of all the membrane units of each membrane module communicates with each other through the stock solution channel 27 of the upper flange chamber; the lower flange chamber 14 uses plates 14a, 14b Etc. is surrounded into a hollow nearly rectangular chamber, forming a horizontal filtrate coll...

Embodiment 2

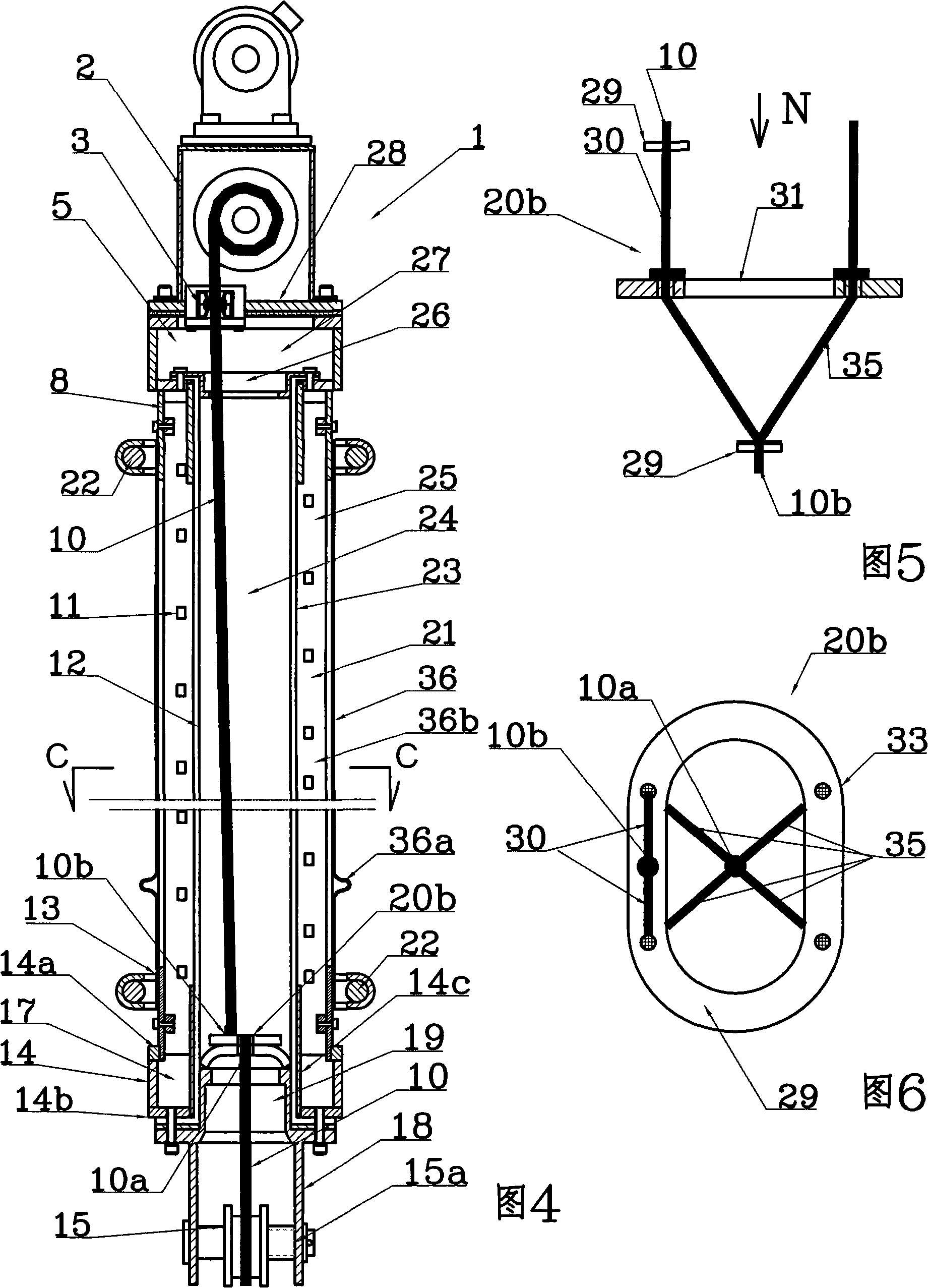

[0062] The difference between this embodiment and Embodiment 1 is that a tubular sealing membrane 36 is arranged outside the tubular grid of the membrane unit, and a closed ring is formed between the tubular sealing membrane 36 and the tubular filter membrane 12, covering the tubular framework 21 to form an annular filter. The liquid collection chamber 36b, the upper end of the tubular sealing membrane 36 is connected and sealed to the branch pipe 8 on the lower end surface of the upper flange chamber 5, the lower end is connected and sealed to the branch pipe 13 on the upper end surface 14a of the lower flange chamber 14, and the annular filtrate collection chamber 36b It communicates with the horizontal filtrate collection chamber 17.

[0063] The tubular closure membrane 36 is a thin-walled tube that is flexible and leak-free; their circular centerlines coincide and are perpendicular to the horizontal. The connection between the upper end of the tubular sealing membrane 36 ...

Embodiment 3

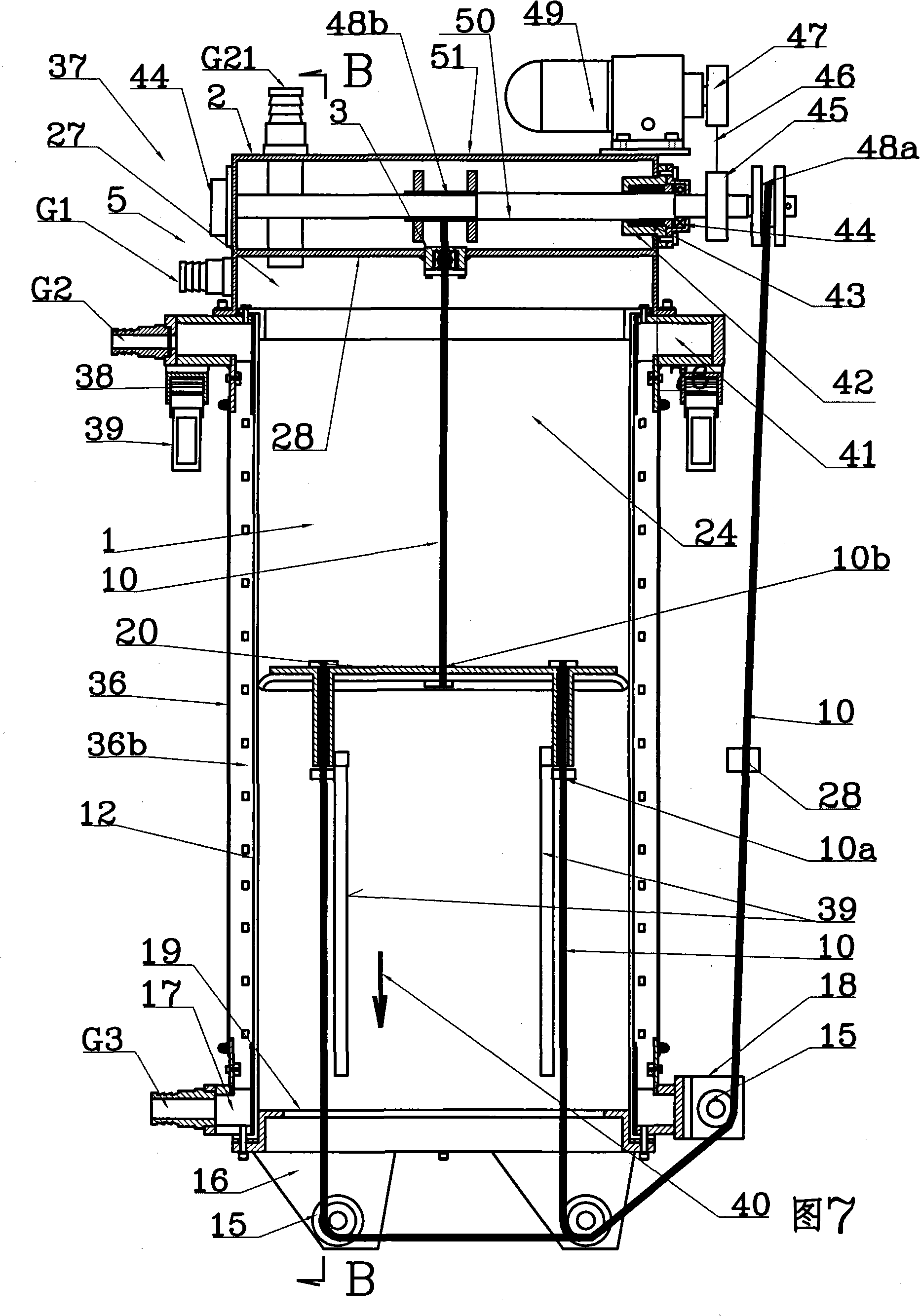

[0066] The inventive equipment in this embodiment includes a filter element and a pressure assembly, each filter element includes four membrane assemblies 37, and each membrane assembly 37 includes a membrane unit 1, an upper flange chamber 5, and a lower flange chamber 14 and mechanical slag discharge assembly; all membrane units 1 of the membrane module are arranged between the upper flange chamber 5 and the lower flange chamber 14; the long axes of the two membrane units 1 of the membrane module 37 are all in a central plane, which plane Respectively coincide with the major axis (row axis) of the upper flange chamber 5 and the lower flange chamber 14 of the membrane assembly's 37 outer flange chambers; the major axes (row axis) of the four membrane assemblies 37 of the filter element are parallel to each other.

[0067] The difference between the membrane unit of this embodiment and Embodiment 2 mainly lies in that: in this embodiment, a fluid combination channel 41 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com