Ceramic filter

A ceramic filter, ceramic technology, applied in the direction of ceramic products, chemical instruments and methods, membranes, etc., to achieve the effect of reducing the amount of use, preventing the increase of pressure loss, and inhibiting infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

[0033] Examples and Comparative Examples

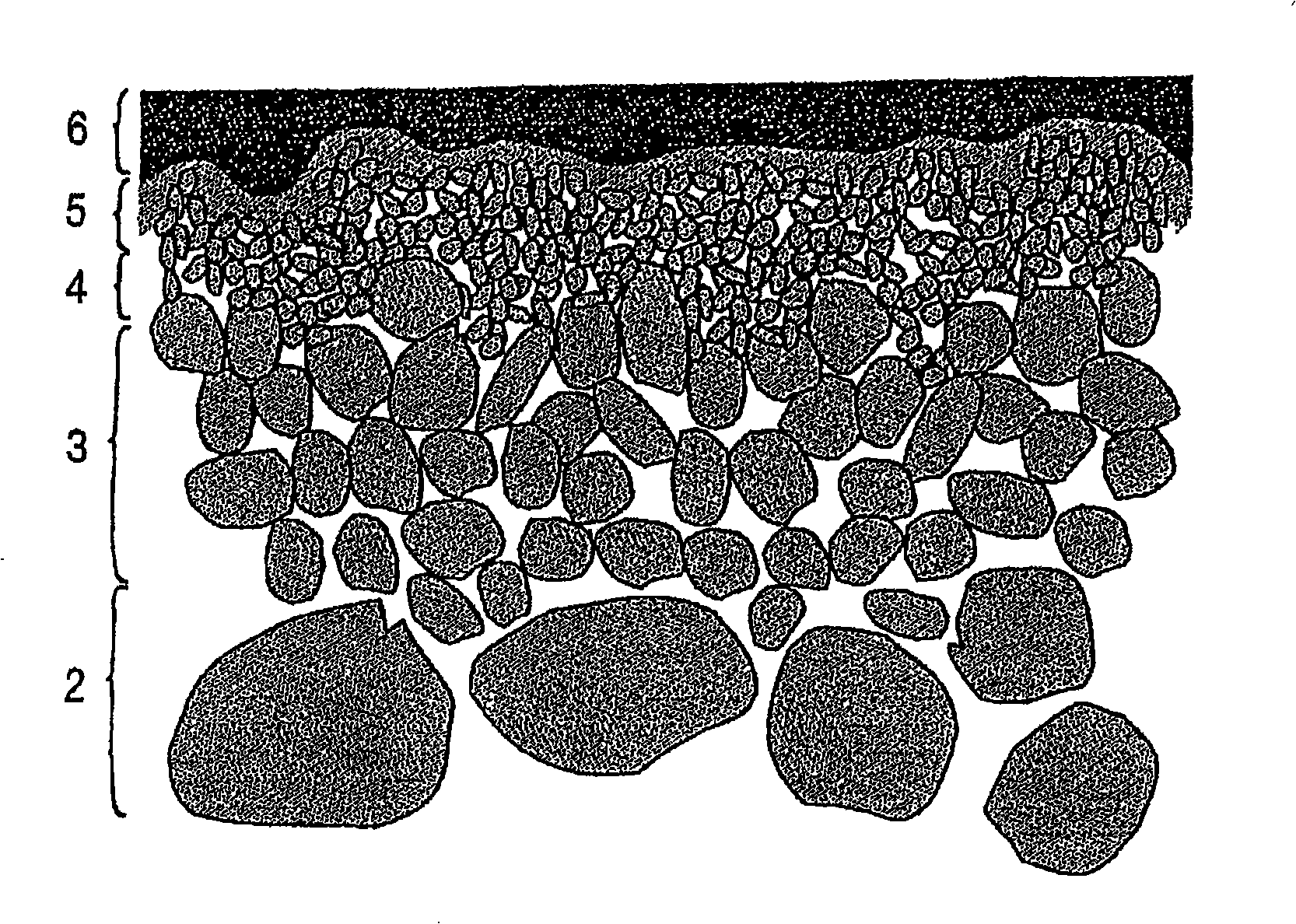

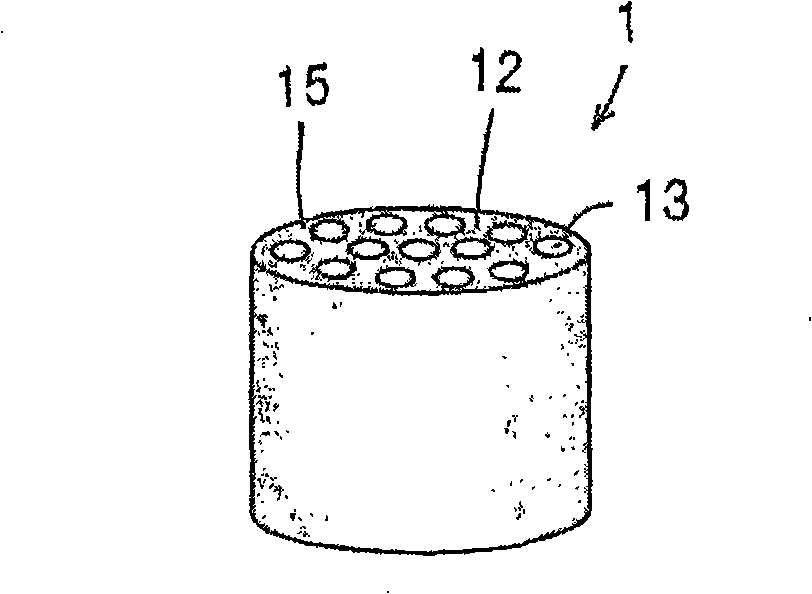

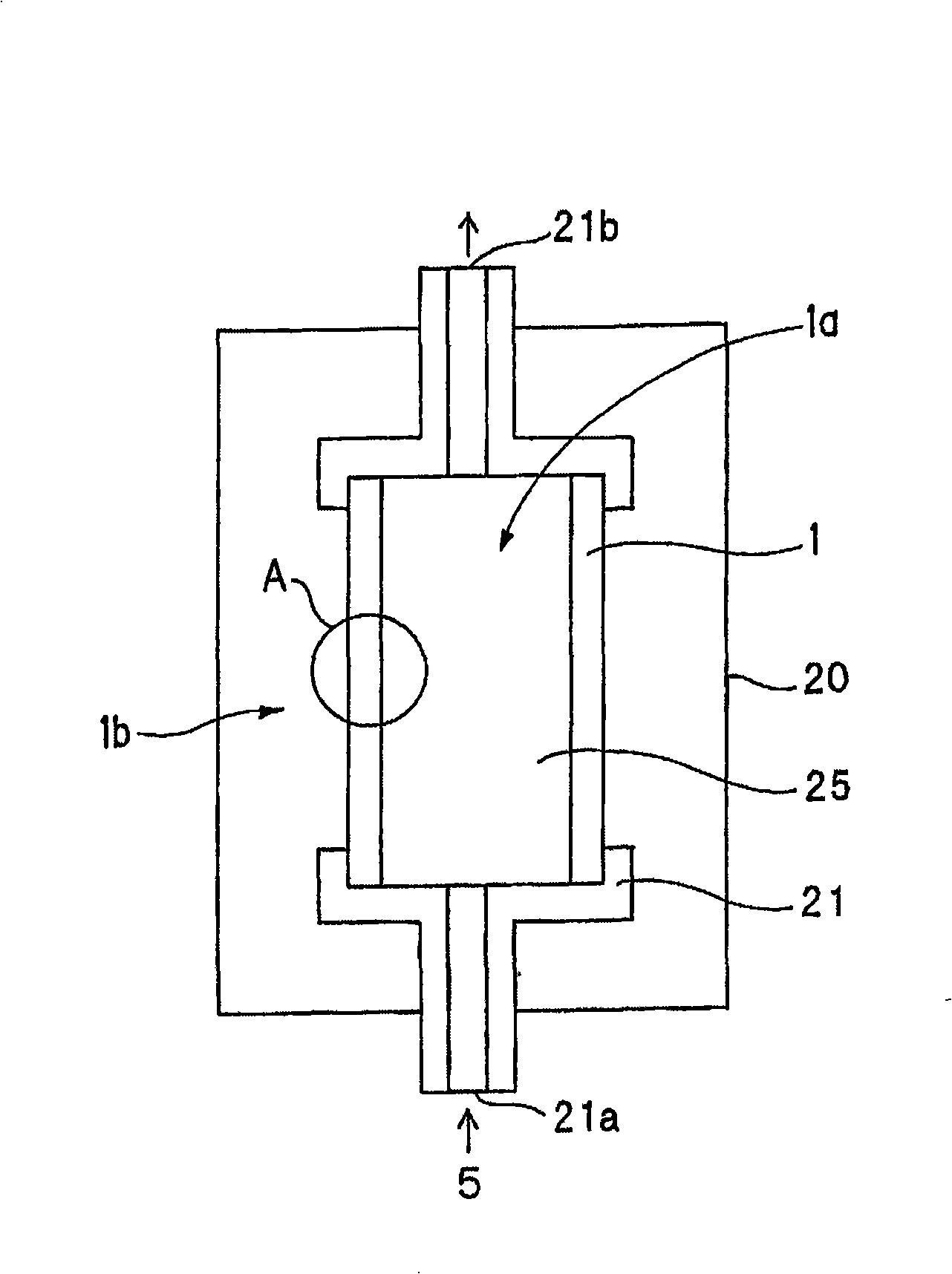

[0034] As described below, a substrate A formed of a monolithic alumina porous substrate, a substrate B on which a first surface dense layer is formed on the substrate A, and a substrate B on which a second surface dense layer is formed Substrate C, substrate D on which the third surface dense layer is formed. In addition, a substrate E similar to the substrate D, which is a cylindrical alumina porous substrate, was formed. Using these substrates A to E, a carbon film layer was formed on the surface of each of the substrates A to E.

[0035] In addition, each base material A-E is demonstrated in detail. The substrate A is a monolithic alumina porous substrate with an average particle diameter of 10 to 100 μm and an average pore diameter of 1 to 30 μm. Substrate B is formed by d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com