Method for recovering tungsten and molybdenum from phosphor middling

A technology for mining and crude phosphoric acid, applied in the field of molybdenum and tungsten recovery, to achieve the effect of simple and easy process and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

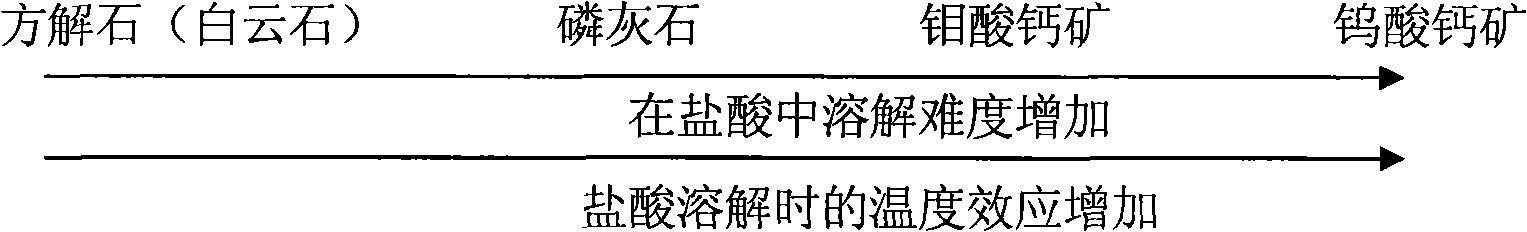

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] with WO 3 17.78%, Mo 5.77% (Mo / WO 3 Mass ratio=32.45%), P 2 o 5 = 18.11% particle size - 200 mesh raw ore 1Kg, no flotation agent removed, C HCl =3.5mol / L, liquid-solid ratio L / T=4 / 1, react at 60°C for 4 hours, and obtain 328g of dry concentrate, which contains WO 3 51.18%, Mo2.51% (Mo / WO 3 =4.90%), WO 3 Direct recovery rate ~ 95%, leachate contains H 3 PO 4 with P 2 o 5 Calculated as ~45g / L.

Embodiment 2

[0034] Raw ore WO 3 25.06%, Mo 4.28% (Mo / WO 3 Mass ratio 17.08%), P 2o 5 =22.57%, without removing flotation agent, leaching process parameter C HCl =4mol / L, L / T=4 / 1 t=70°C

[0035] τ=4hr, the leachate contains H 3 PO 4 with P 2 o 5 Calculated as ~56g / L, the tungsten concentrate contains WO 3 58.76% Mo = 2.957% Mo / WO 3 =5.03%, molybdenum leaching rate 64.97%, tungsten loss rate 1.34%

Embodiment 3

[0037] Raw ore WO 3 21.22%, Mo 2.59%, P 2 o 5 =23.88%, remove flotation agent in advance, leaching conditions: t=55℃, τ=2hr, L / T=6 / 1, C HCl =3.2mol / L, containing H 3 PO 4 Leaching solution is P 2 o 5 Total 39g / L, at the same time get tungsten concentrate containing WO 3 67.65%, Mo 3.16%, Mo / WO 3 Mass ratio 4.67%, WO 3 Dissolution rate 2.7%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com