Thick coating material purifying air and preparing method thereof

A coating material and air purification technology, which is applied in the field of thick coating materials and interior wall coating decoration materials, can solve problems such as poor durability, low efficiency of harmful gases, and harsh light source requirements, and achieve long-lasting purification effects and good The effect of the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

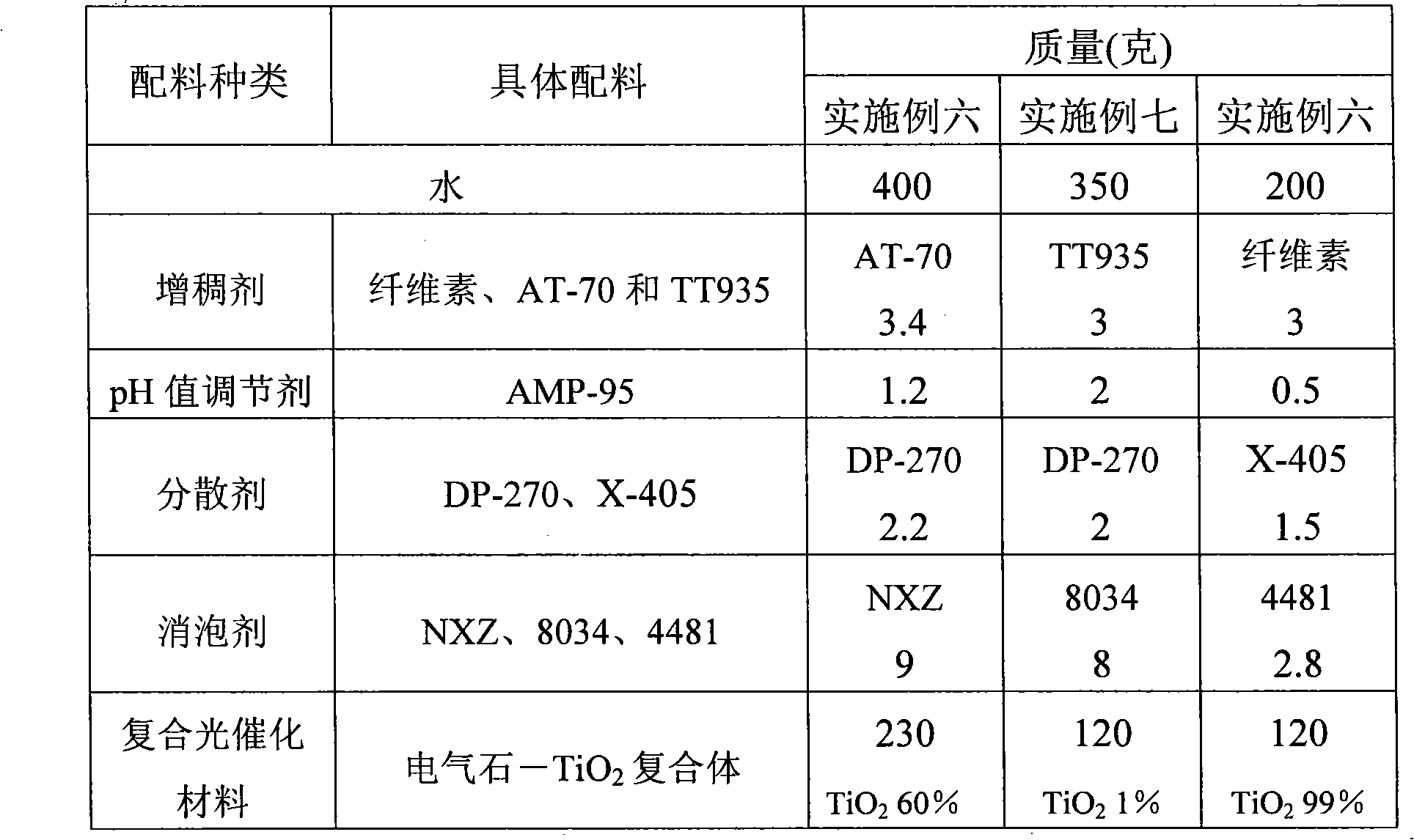

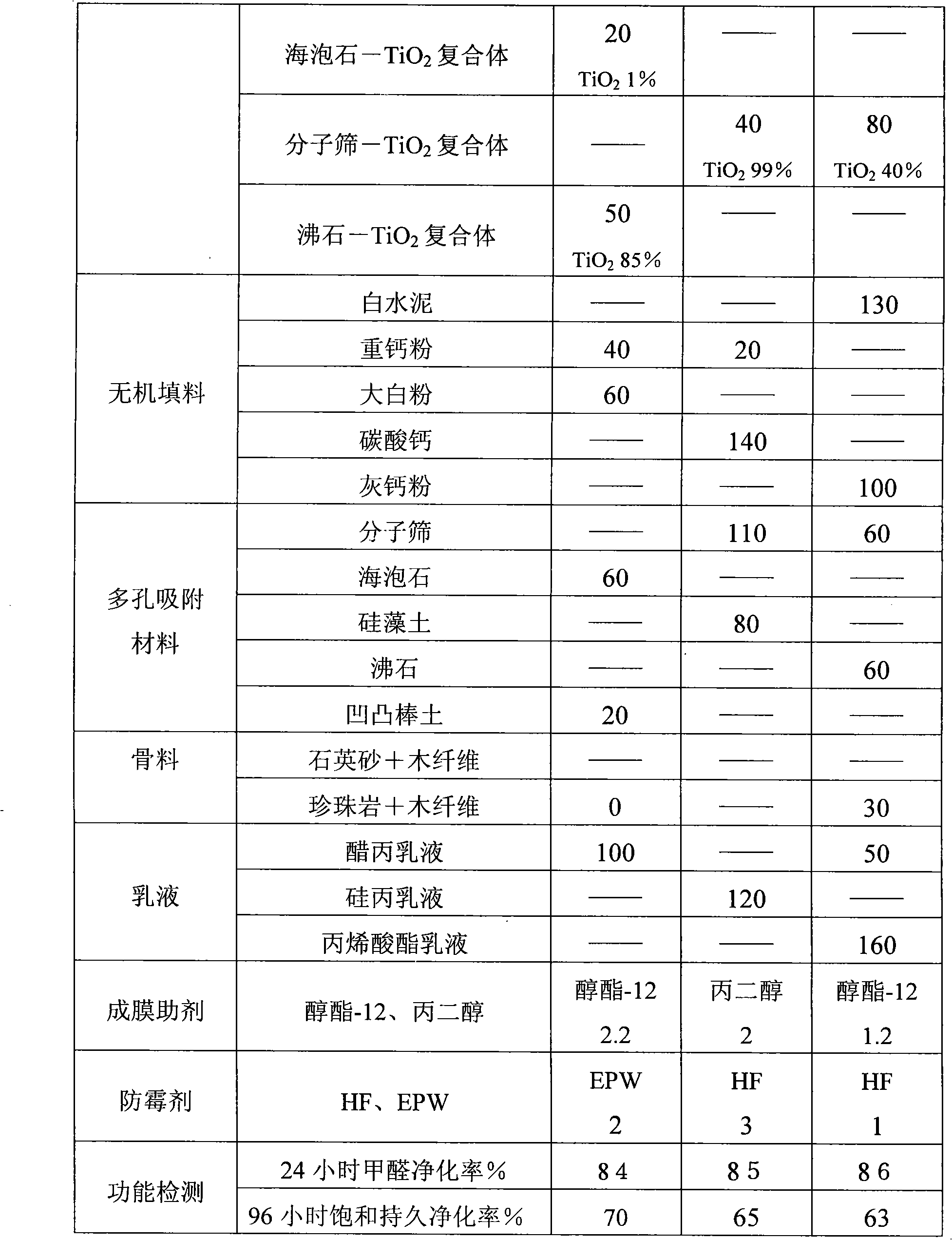

[0041] Embodiment 1: Prepare the coating material of this example according to the following components and the above method.

[0042] Component Quantity (g)

[0043] water 380

[0044] pH regulator AMP-95 1

[0045] Dispersant DP-270 2

[0046] Defoamer 4481 1

[0047] Tourmaline composite TiO 2 180

[0048] (with TiO 2 95%)

[0049] meerschaum 80

[0050] Zeolite 100

[0051] heavy calcium 50

[0052] Talc 70

[0053] Styrene acrylic emulsion 120

[0054] Propylene Glycol 15

[0055] Thickener AT-70 1

[0056] The coating produced by this product was tested for its purification function according to the standard "Purification Performance of Coating Materials with Indoor Air Purification Function" JC / T1074-2008. Paint the sample on one surface of four 500mm×500mm glass plates, let it dry naturally for 7 days and put it in 1m 3 In the sealed chamber, 3 μL of formaldehyde solution was added dropwise, and the purification rate of formaldehyde by the coa...

Embodiment 2

[0057] Embodiment 2: Prepare the coating material of this example according to the following components and the above method.

[0058] Component Quantity (g)

[0059] water 300

[0060] Dispersant X-405 1.5

[0061] pH regulator AMP-95 2

[0062] Ethylene glycol 8

[0063] Thickener B03 5

[0064] Tourmaline composite TiO 2 150

[0065] (with TiO 2 90%)

[0066] Sepiolite composite TiO 2 20

[0067] (with TiO 2 10%)

[0068] Molecular sieve 120

[0069] Quartz sand 64

[0070] wood fiber 16

[0071] Talc 60

[0072] Heavy calcium powder 100

[0073] Styrene acrylic emulsion 150

[0074] Alcohol ester-12 2

[0075] Antifungal agent HF 1.5

[0076] Use the same method as in Example 1 to carry out functional testing on the product of this example. The results show that the purification rate of formaldehyde in the coating reaches 84% in 24 hours, and the saturated and durable purification rate in 96 hours reaches 66%.

Embodiment 3

[0077] Embodiment 3: Prepare the coating material of this example according to the following components and the above method.

[0078] Component Quantity (g)

[0079] water 280

[0080] Cellulose 1.5

[0081] pH regulator AMP-95 1

[0082] Wetting and dispersing agent DP-270 2

[0083] Defoamer 4481 4

[0084] Molecular sieve composite TiO 2 100

[0085] (with TiO 2 80%)

[0086] Molecular sieve 30

[0087] Diatomaceous earth 70

[0088] Perlite 22.5

[0090] Talc 160

[0091] Heavy calcium powder 140

[0092] Styrene acrylic emulsion 180

[0093] Alcohol Ester-12 5

[0094] Thickener RM-8W 1.5

[0095] Use the same method as in Example 1 to carry out functional testing on the product of this example. The results show that the purification rate of formaldehyde in the coating reaches 84% in 24 hours, and the saturated and durable purification rate in 96 hours reaches 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com