Long-stroke pneumatic hydraulic cylinder body and its processing method

A pneumatic-hydraulic and processing method technology, applied to cylinders, engine components, mechanical equipment, etc., can solve problems such as poor oil storage capacity, large friction in the cylinder, and short service life, so as to prolong service life, reduce heat, and expand use range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

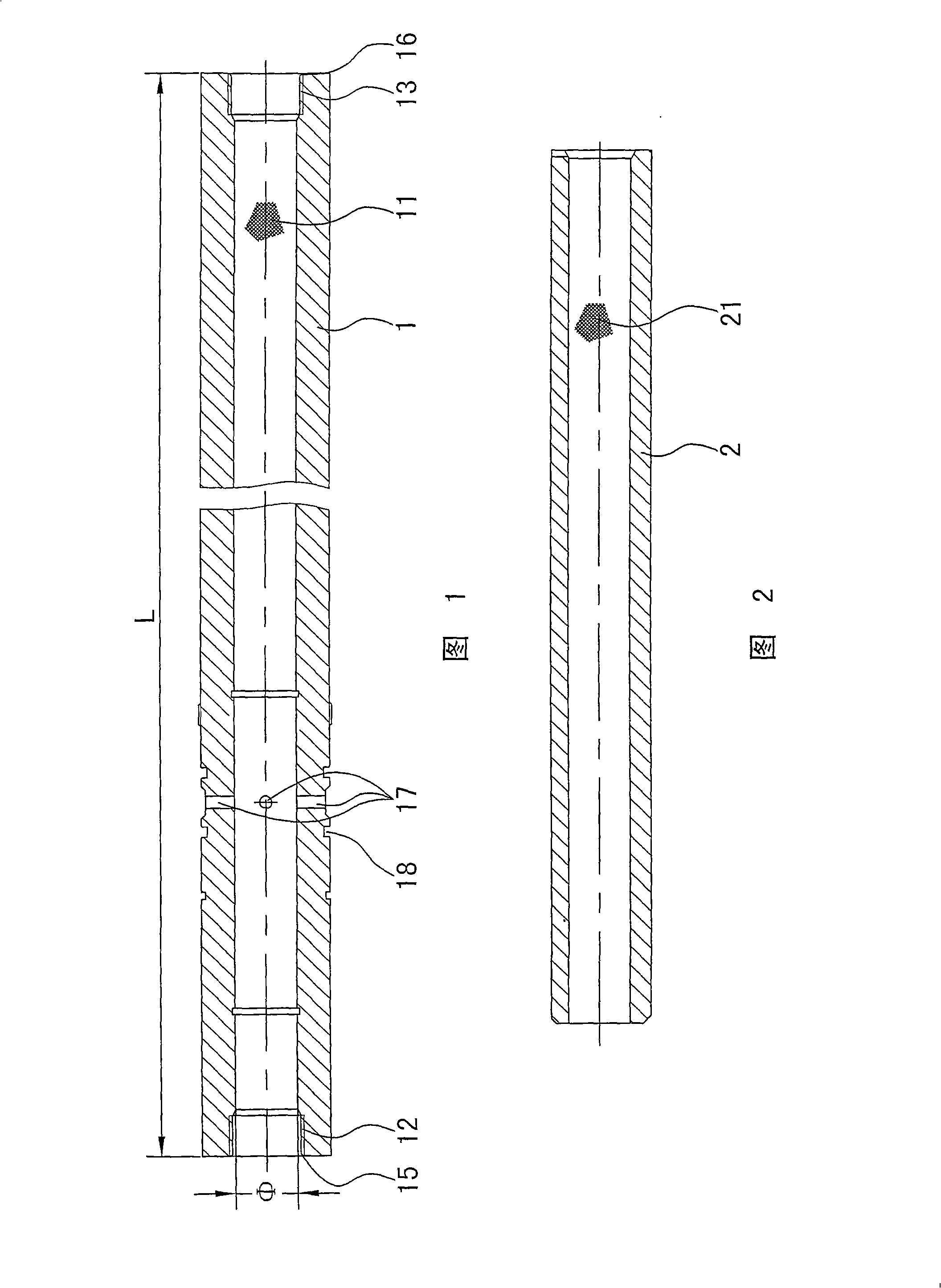

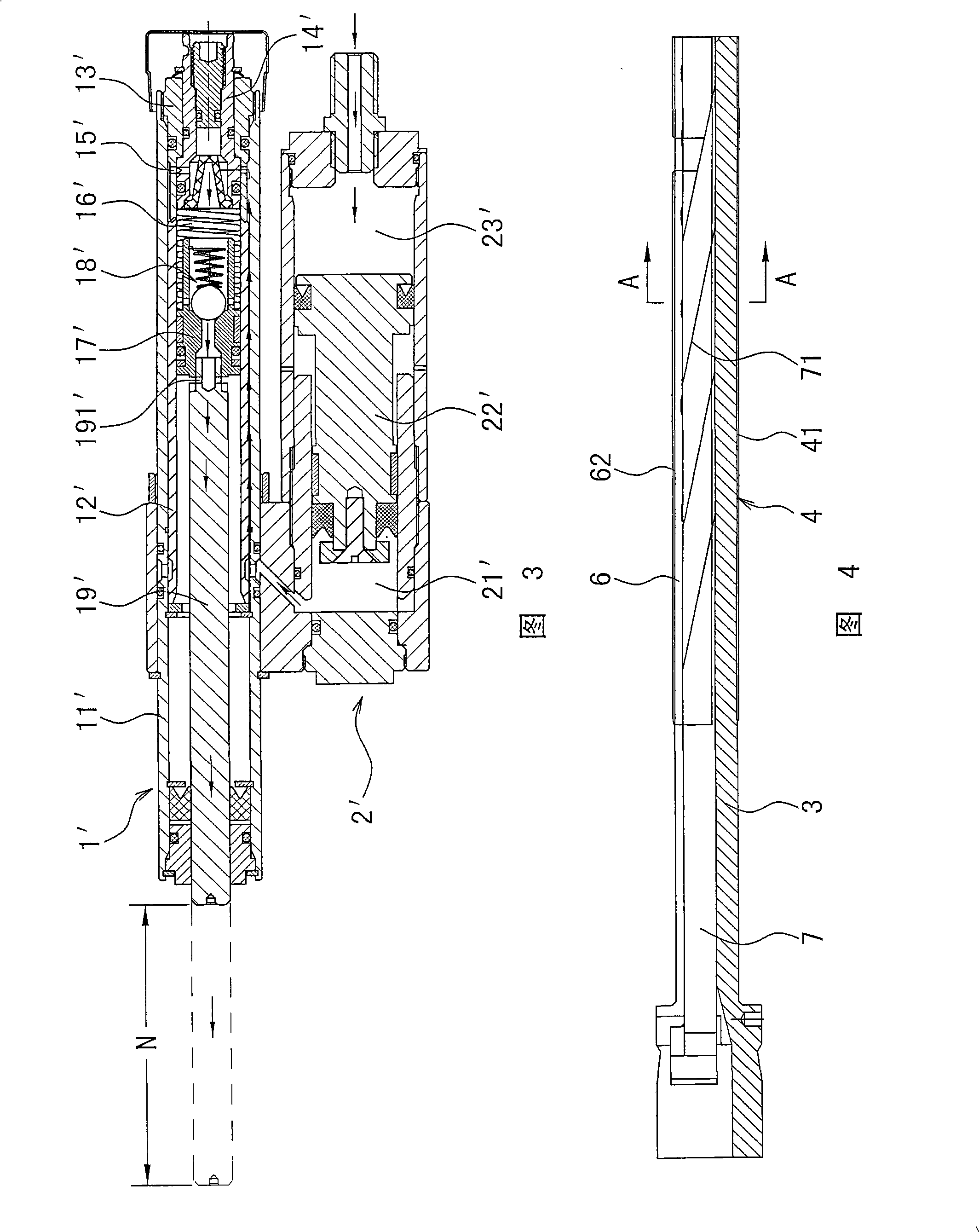

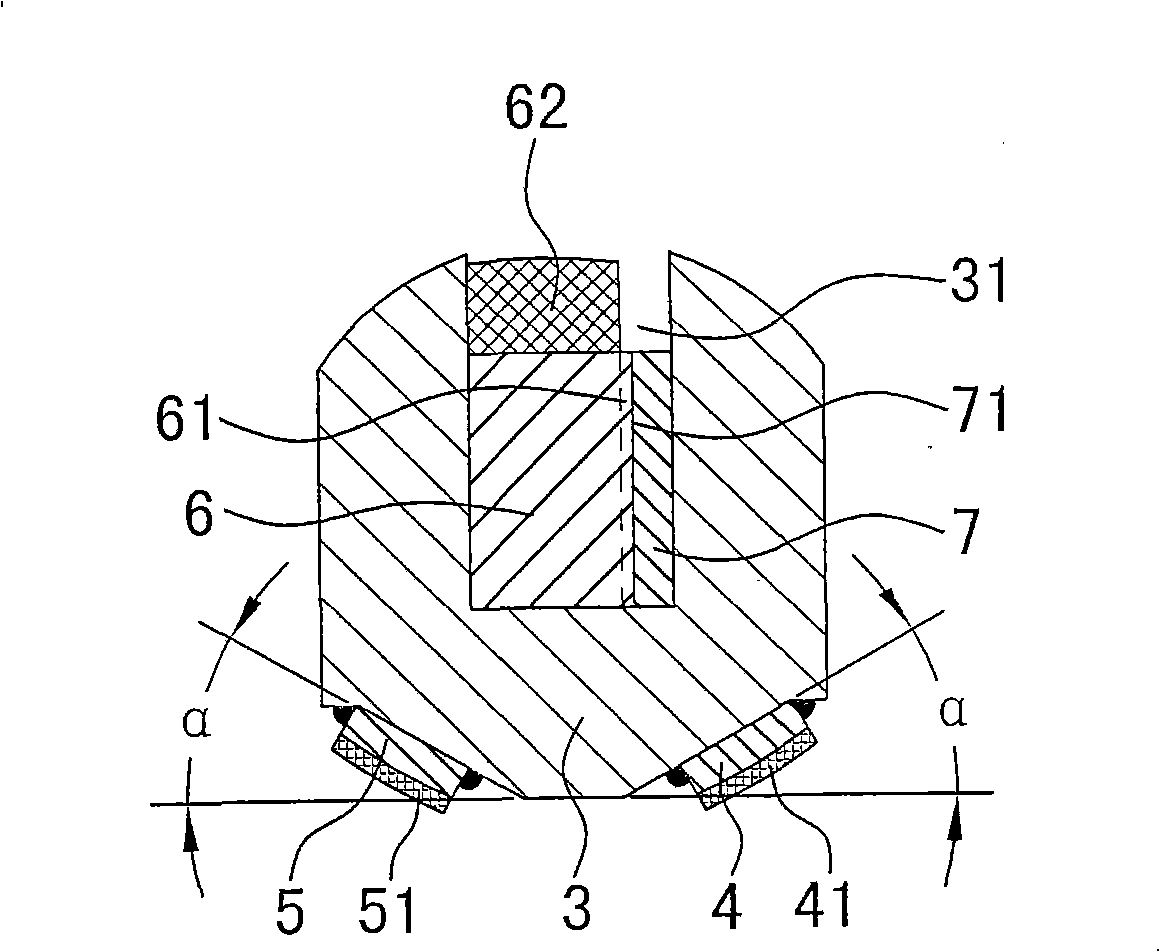

[0027] The invention discloses a long-stroke pneumatic-hydraulic governor, as shown in Fig. 1 and Fig. 2, comprising an outer cylinder body 1 and an inner cylinder body 2 made of circular steel pipes, and the middle part of the outer cylinder body is provided with an oil passage Holes 17, oil through holes communicate with the hydraulic chamber of the cylinder block, and are characterized in that the inner wall surfaces of the outer cylinder body 1 and the inner cylinder body 2 are respectively shaped with grids 11, 21, and the grids 11, 21 are extremely small, It is invisible to the naked eye, but it is still very smooth to the touch. Lubricating oil can be stored in the grids 11 and 21, so that the outer cylinder body 1 and the inner cylinder body 2 can be kept lubricated for a long time, and the friction of parts such as pistons and sealing rings can be greatly reduced. Wear, prolong service life, and reduce heat generated by wear. The length L of the outer cylinder 1 is 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com