Steel scoria processing method

A treatment method and technology for steel slag, which are applied in chemical instruments and methods, wet separation, magnetic separation, etc., can solve the problems of unenvironmental protection and low utilization rate of waste slag treatment, and achieve the effect of large yield, elimination of pollution and high economic benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

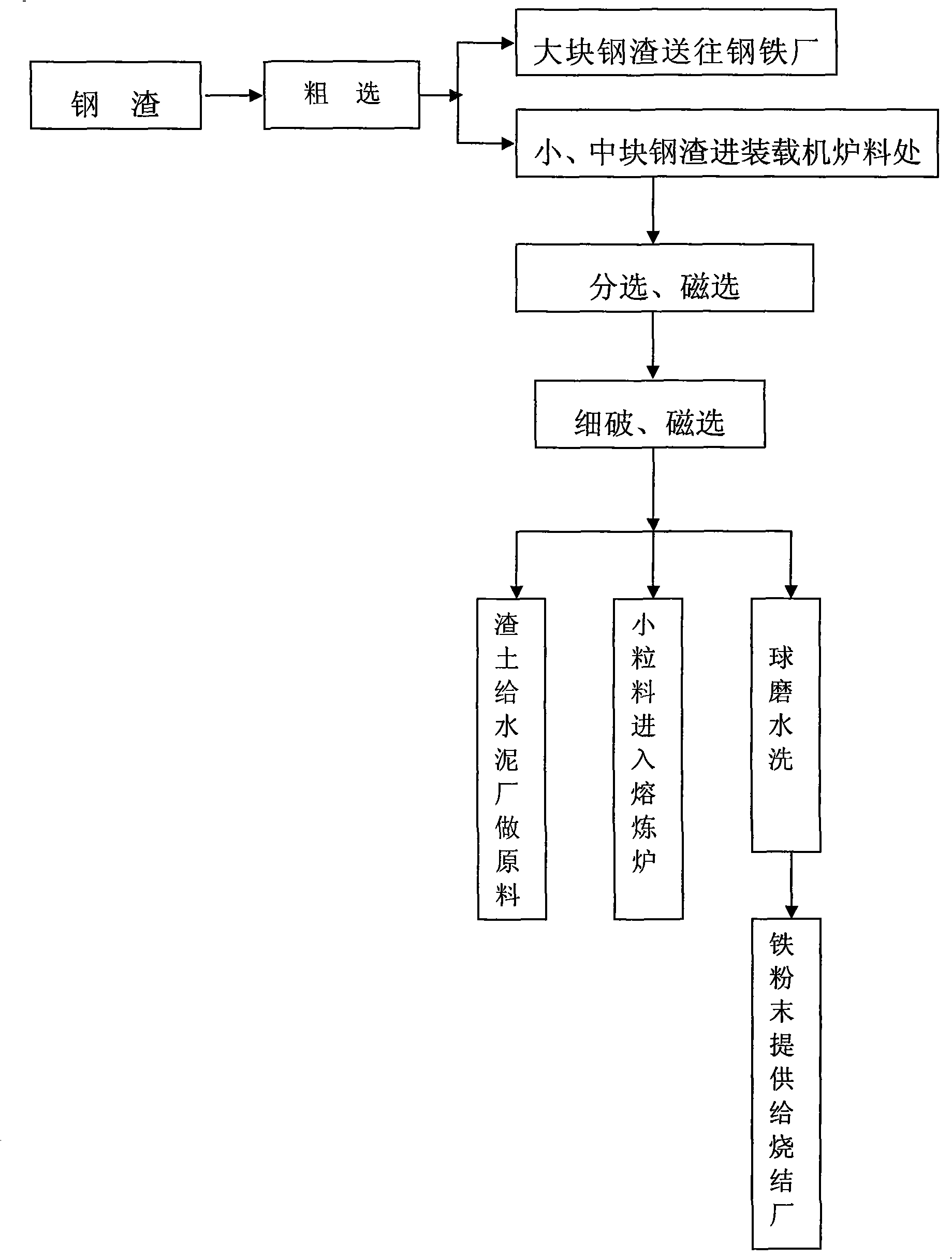

Image

Examples

Embodiment 1

[0014] 1) Rough selection: Load the material into the vibrating screen with a loader for rough separation and vibration separation. The purpose is to distinguish the large steel slag above 150mm from the small and medium steel slag below 150mm. The iron content of large steel slag is 70% The above can be directly sent to the steel mill for re-melting, and the remaining large slag has a low iron content, which is sent to the jaw crusher for crushing, and the particle size of the discharge port is 20-60mm, and mixed with small and medium-sized materials;

[0015] 2) Classify and magnetically separate the medium and small pieces of steel slag mixture. The classification is mainly to treat the steel slag with a particle size of about 50-150mm through a magnetic separator to separate the slag from the iron. After this process, the steel slag with an iron content above 50% The steel slag is sent to the iron factory to return to the furnace, and the remaining part of the slag enters t...

Embodiment 2

[0020] 1) Rough selection: Raw materials enter the vibrating screen, screen out large pieces of steel slag with a particle size of 300mm or more and an iron content of 65-75%, and send them directly to the iron and steel plant for recycling, and send the large pieces of slag with a particle size of 150-300mm to the jaw crusher Carry out coarse crushing, the particle size of the discharge port is 20-60mm, and mix with medium and small pieces of steel slag with a particle size below 150mm, and send it to the magnetic separator and vibrating screen for separation through the conveyor;

[0021] 2) Sorting and magnetic separation: Steel slag with a particle size of 20-150mm, after magnetic separation, the steel slag with an iron content of more than 50% is directly sent to the ironworks for return to the furnace, and the steel slag with a size of 50-80mm is screened out for fine crushing;

[0022] 3) Fine crushing and magnetic separation: the steel slag with a particle size of 50-80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com